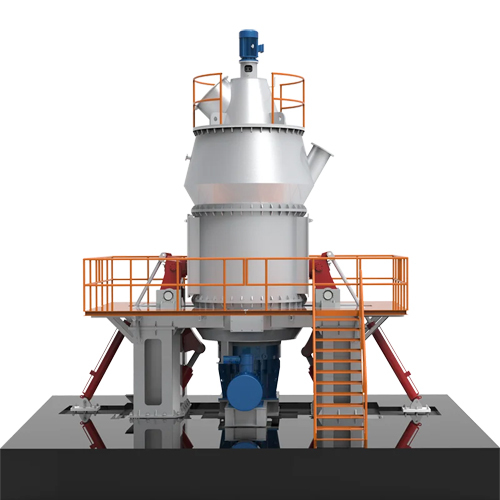

Vertical Roller Mill - Clinker Grinding Efficiency Maximized | Low Power Consumption, Long Wear Parts Life, Optimized Roller And Disc Design

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Variable |

| Power | Variable |

| Capacity | Variable |

| Efficiency | High |

| Weight | Variable |

| Controller | Frequency |

| Features | High Efficiency, Low Energy, Compact Design, Long Lifespan, Easy Operation, Durable Parts, Precise Grinding, Low Vibration, Reliable System |

Product Overview

Key Features

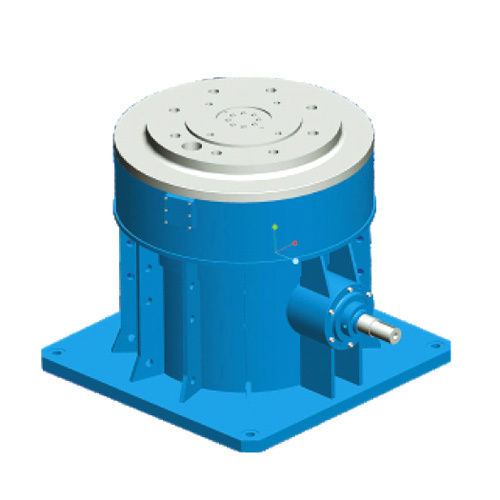

The features of Vertical Roller Mills are: the roller and disc are optimistically designed for higher grinding efficiency and low energy consumption; the powder separator is cage rotor type, the motor is frequency controlled and the powder separating efficiency is improved; the roller rising device is added and low or zero load start is realized; the horizontal buffering device of pressure frame is added to reduce the vibration of the mill; outside material circulating is used to reduce the wear of the mill and the electricity consumption; central feeding and long service lives of wearing parts.

We are also offering::

Copper Mould

Customized Copper Mould

Ball Valve

Blow Off Valve

Control Valve

Thermal Valve

Check Valve

Blast Furnace

Sinter Plant

Silica Bricks

Water Jacket

Graphite Electrode

Company Details

Focusing on a customer-centric approach, CIMM GROUP CO. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Get Machineries from CIMM GROUP CO. LTD. at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Establishment

1998

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Dalian, Liaoning

Marketing Manager / Ge Engineer

Mr. Alex

Address

Zhiye Square Building, 2nd Floor, No. 135#-137#, Guangxian Road, High-tech Park District, Dalian, Liaoning, 116085, China

vertical roller mill in Dalian

Report incorrect details