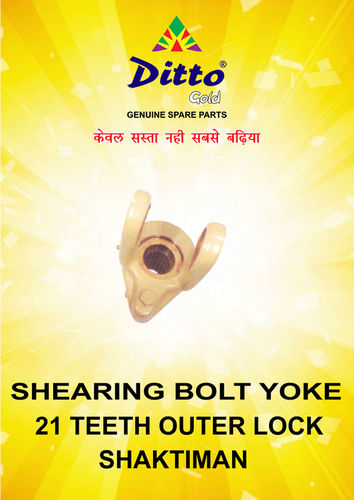

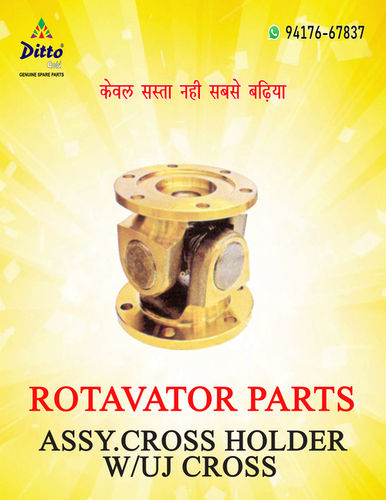

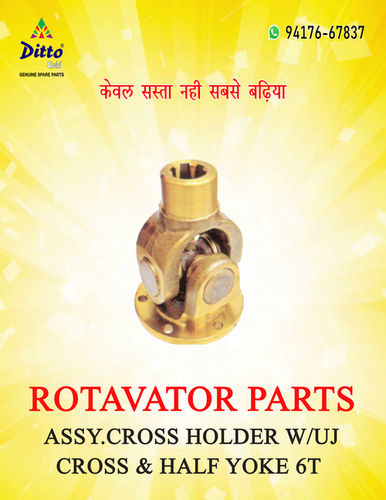

Uj Cross Lock - Metal Design | Durable Construction, Versatile Locking Mechanism For Secure Applications

Price: 2.11 INR / Piece

Get Latest Price

Minimum Order Quantity :

12 Piece

Brand Name :

Ditto Gold

In Stock

Product Specifications

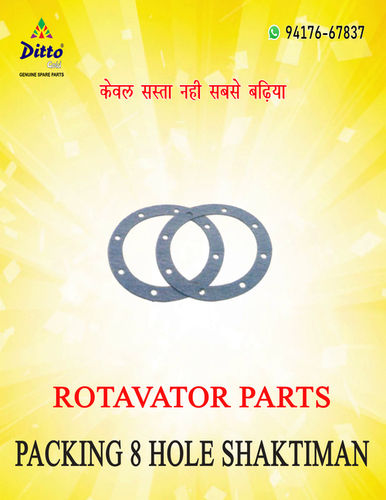

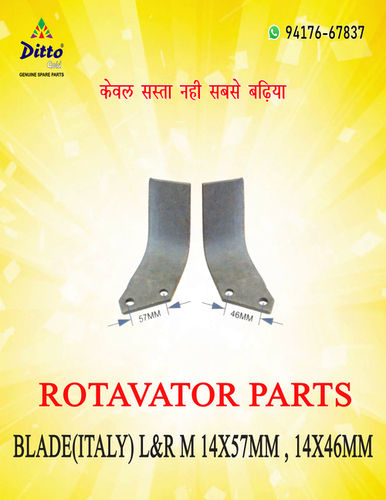

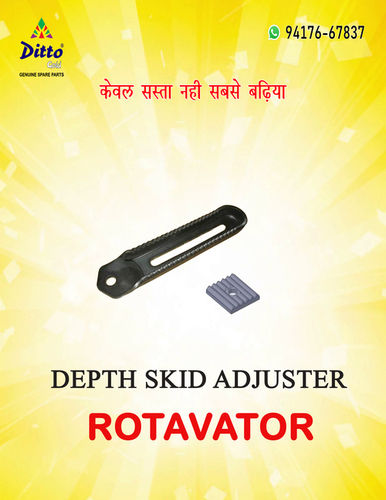

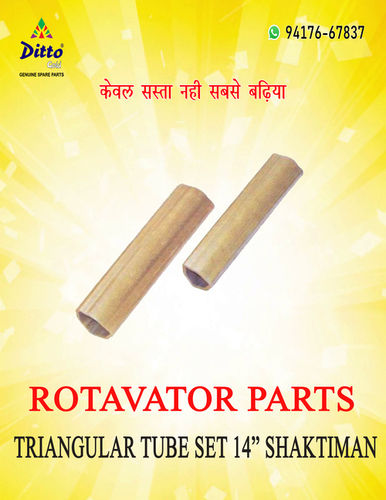

| Product Type | Rotavator Part |

| Material | Metal |

| Supply Ability | 100 Per Week |

| Delivery Time | 1-2 Days |

Company Details

Business Type

Manufacturer, Supplier

Employee Count

32

Establishment

1973

Working Days

Monday To Sunday

GST NO

03AAUPG5293P1ZZ

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 03AAUPG5293P1ZZ

Ludhiana, Punjab

Director

Mr Vishnu Vishnu Aggarwal

Address

11230, Partap Nagar, St.No.5, Near Shiv Mandir, Ludhiana, Punjab, 141003, India

uj cross in Ludhiana

Report incorrect details