Two Stage Vacuum Pump - Cast Iron & Stainless Steel Components, 720 Mm Of Hg Maximum Vacuum | Oil Free Exhaust, High Efficiency, Low Maintenance

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Cast iron, SS304 |

| Stages | Two |

| Vacuum Level | 735 mm Hg |

| Usage | Chemical, pharmaceutical, water treatment, beverage industries |

| Power Saving | 50% |

| Efficiency | High |

| Construction | Simple |

| Features | High vacuum, High capacity, Energy efficient, Low maintenance, Oil-free exhaust, Versatile usage |

Product Overview

Key Features

Our

immense domain expertise and market knowledge assist us manufacture, export and supply the finest quality Two

Stage Vacuum Pump

to

the clients.

This

pump is precisely manufactured under the strict guidance of our

diligent technical experts using hiqh quality raw material like cast iron, bronze, SS 304, SS316, Alloy 20, hastalloy - C and Rubber

with the help of cutting-edge technique in accordance with set

industry norms. Offered pump is mainly used in chemical, pharmaceutical,

water treatment, beverage and other allied industries. Moreover, we

provide this Two

Stage Vacuum Pump

in

numerous technical specifications to the clients.

Features:

Moist air, aggressive

gases, vapors & dust laden gases can be handledhigher capacity at higher

vacuum as compare to single stage vacuum pumpNo metallic contact inside

machine, less wear & tearNo contamination of medium

passing throughSimple & Trouble free

operationOil free exhaust

No lubrication

Compression takes place

with small temperature rise.Simple construction

Easy Maintenance

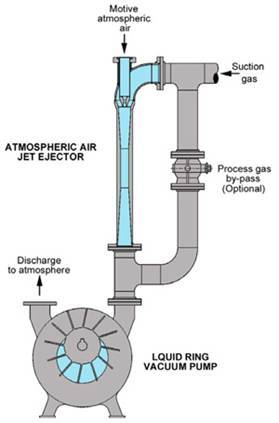

Construction and Working:

Two-stage vacuum pumps develop maximum vacuum of 720

mm of Hg, when sealing water temperature is 30C (755 mm of hg

baro-metric pressure and suction temperature of 30C)and

achieves vacuum up to 735 mm of Hg, when sealing water temperature is

15C to 18C. Due to the latest technology and

design, it so happens that a smaller model may require as compared to

a single-stage vacuum pump. In the conventional Single stage

vacuum pump the performance after 70% vacuum falls down drastically,

whereas the Two stage vacuum pump gives better performance after 70%

vacuum. Normally the vacuum pump requires to run consistently between

70 to 90% vacuum. In first stage, after creating vacuum up to

70% the compressed air / vapor mist with sealing media is led to the

Second stage working chamber via crossover manifold. Second stage

enhances the vacuum generated by the First stage. This way,

Two stage water ring vacuum pump gives nearly 50% more volumetric

efficiency after 70% vacuum with the same electric motor rating. This

results saving of nearly 50% power.

Company Details

Focusing on a customer-centric approach, VINDI VAK PUMP PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Pumps & Pumping Equipment in bulk from VINDI VAK PUMP PVT. LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

100

Establishment

1985

Working Days

Monday To Sunday

GST NO

24AAACV5009R1Z1

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AAACV5009R1Z1

Ahmedabad, Gujarat

Mr. Dinesh Patel

Address

Plot No. 1905, 1906, Phase IV, Near CIPET, GIDC, Vatva, Ahmedabad, Gujarat, 382445, India

vacuum pump in Ahmedabad

Report incorrect details