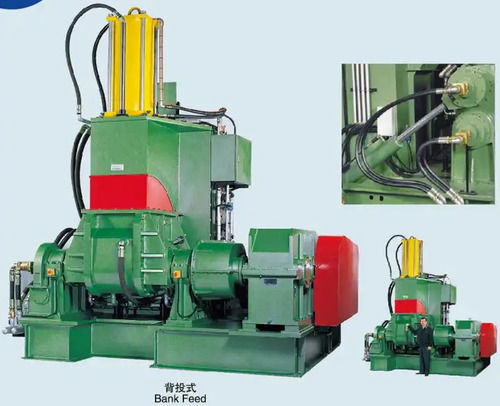

Semi-automatic Two-roll Rubber Butter Mixing Machine

Price: 4000 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Type | Open Mixing Mill |

| Material | Stainless Steel |

| Capacity | 3 Kg/hr |

| Computerized | Yes |

| Automatic Grade | Semi-Automatic |

| Control System | Human Machine Interface |

| Cooling System | Water Cooling |

| Rolller Speed | 19 RPM |

| Max. Diameter | 16 Inch (in) |

| Power Consumption | 5.5 Kilowatt (kW) |

| Voltage | 220 Volt (v) |

| Weight | 690 Kilograms (kg) |

| Dimension(L*W*H) | 1490 * 600 * 1390 Millimeter (mm) |

| Warranty | 12 months |

| FOB Port | Shenzhen |

| Payment Terms | Cash on Delivery (COD), Letter of Credit (L/C), Paypal, Western Union, Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Delivery Point (DP), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA) |

| Supply Ability | 200 Per Month |

| Delivery Time | 20 Days |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | Wood Packaging |

| Main Export Market(s) | Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa |

| Main Domestic Market | All India |

| Certifications | CE |

Product Overview

Key Features

Feature

Introduction:

Two roll mixing machine are engineered to provide unmatched performance for masticating and kneading natural rubber,synthetic rubber , EVA or PVC pellets with various chemical materials,This machine is mainly used to plastic ,hot mill and mixing mill of natural and synthetic rubber for rubber product factory

Application:

Plastic open two roll mixing mill. It is widely used in rubbers and plastics industry for polymer mixing, such as PVC, color master batch. It consists of roll, bearing, gap adjusting device, electric control system, safety device, etc.

Feature:

1. Construction of mill rolls: drilled roll, bored roll, grooved roll

2. We can design speed ratio as per customers' formula and processing requirements.

3. Frame, frame cap and base are welded and treated by annealing for stress relieving.

4. Rolls material is chilled cast alloy iron which hardness is reach to 70HB.

5 Brake and emergency stop device can ensure the safety of personnel and equipment.

6 Auto feeding oil or grease lubrication, it is easy to maintain and protect machine.

7 Human nature designed controlling system ensure labor safety.

8 Methods of adjusting roll nip: manual or electric

Intelligent control panel and PLC control system:

1. Real-time data record and export of kneading time, temperature (mixing chamber and front/rear rotors), ram pressure, current, torque and recipe code.

2. The control system can be set up to 20 mixing steps, save 20 recipe spaces.

3. The control system is capable of remote import of the process recipe and data monitoring, communicating with MES via Ethernet communication interface.

4. An Ethernet communication interface and 20% of the control points are reserved. Touch screen is provided.

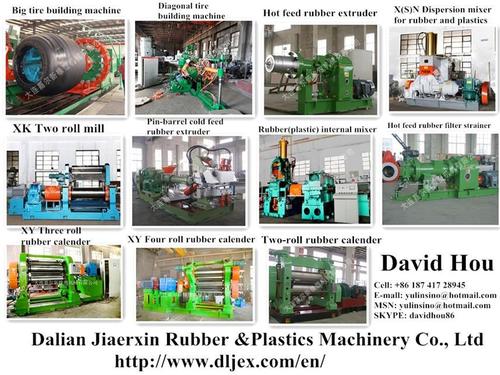

Related Products

More Product From This seller

Company Details

Business Type

Exporter, Manufacturer, Supplier, Wholesaler, Producer

Employee Count

22

Establishment

2002

Working Days

Monday To Saturday

Payment Mode

Telegraphic Transfer (T/T)

Explore Related Categories

Seller Details

Dongguan, Guangdong

Sales Manager

Mr Judeon Zhou

Address

Gangkou Rd, Luo Yong Country, Xinhe, Wanjiang, Dongguan, Guangdong, China

rubber mixers in Dongguan

Report incorrect details