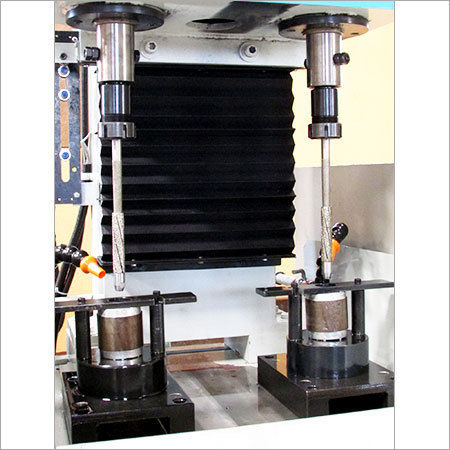

Twin Spindle Honing Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Motor | Servo Motor |

| Guides | Lm Guides |

| Control | Plc Based |

| Drive | Vfd |

| Spindle | Double |

| Tool | Diamond Coated |

| Features | Easy Operation, High Fluency, Long Life, Precise Honing, Improved Finish, High Productivity, Cost Effective |

Product Overview

Key Features

Outfitted with a latest technical setup and highly skilled team of professionals, we are engaged in manufacturing and supplying Twin Spindle Honing Machine. This machine is mainly used to correct the taper and roundness of work piece bore & also to improve the surface finish. We manufacture this machine using high quality steel. This Twin Spindle Honing Machine comprises of servo motor, electric panel and ball screw arrangements. We offer this machine at cost effective prices.

Features:

- Easy to operate

- High operational fluency

- Longer working life

Twin Spindle Single Pass Honing Machine

Honing Process

Honing process is defined that, it is a method of removing the material from work piece bore by pressurizing the honing tool with reciprocating and rotation of honing tool with coolant. Diamond coated single pass tool once passes in the component bore & finish the honing operation.

Honing Process is used to correct the taper, roundness and improve the surface finish of the work piece bore.

It is very productive process and achieves better geometrical accuracy as compared with grinding operation.

Honing Machine Details

The machine structure is steel fabricated and machined for better accuracy. The Honing head is mounted on LM Guide ways & LM Blocks provided on machine column. The spindle is mounted in the honing head and rotated by Electric Motor. The honing head reciprocation is with Ball Screw arrangement and drive with Servo Motor. Servo motor and Gear box are provided to rotate the Index plate. Electric Panel and Control panel is attached to the machine body.

The PLC is used to interface the honing machine operations. It is logically programmed with machine operation sequences and controls the honing operations. Necessary interlocks are provided. PLC is used to minimize the electric material and make compact electric panel. Proximity switches are provided to set the required length of stroke. Variable Frequency Drive (VFD) is used to regulate the speed of Spindle rotation. Servo Motor Drives are used to regulate the speed of reciprocation of the honing head and Index plate.

The Machine is designed for productivity and the same time to achieve the required accuracy of the components. The various components can be honed on the same machine by replacing only honing tool and fixtures. The machine will be provided with required tooling and fixtures. Set up time is very less to reduce operator fatigue and more productivity.

Machines are user friendly and very easy to operate. Special care has been taken in designing and building the machine for smooth working and low noise level.

Machine Features

- Machine structure is steel fabricated and machined for better accuracy.

- PLC is used to control and interface the machine operations.

- Servo motors are used for vertical movements and for Index table.

- LM Guides & Blocks are used to run machine smoothly and low noise level.

- Various components can be honed on the same machine.

- Machine is very compact & designed for productivity and accuracy.

TECHNICAL SPECIFICATIONS

| Parameters | Specifications/ Make |

| Honing Range | |

| Minimum dia. | 6 mm. |

| Maximum dia. | 30 mm |

| Spindle Stroke | 100 mm |

| Honing Length | 50 mm |

| Spindle & Head details | |

| No. of Spindle | Two (2) |

| Spindle Drive | Electric Motor |

| Spindle speed | 0-1000 rpm. Variable with VFD |

| Honing Head reciprocation | Servo Motor |

| Reciprocation Speed | Variable with Servo motor drive. |

| Index Plate rotation | Variable with Servo motor drive. |

| Honing Tool | |

| Single pass honing m/c | Diamond coated single pass honing tools. |

| Honing tool adaption | Floating type. |

| LM Guide Ways & Ball Screw | |

| LM Guides and Blocks | Hiwin/PMI or equivalent |

| Ball Screw & Nut | Hiwin/PMI or equivalent |

| Electrical Material | |

| Operating Voltage | 415 V, 3 phases, 50 Hz |

| Control Voltage | 220V / 24 V |

| PLC | Delta / Omron or equivalent |

| Electric material | Telemechnics/ABB/ Schneider or equivalent |

| Other Details | |

| Lubrication System | Automatic Lubrication |

| Floor Space W x B x H approx | 800 x 800 x 2400mm approx. |

| Machine Weight | 1 ton approx. |

| Color | Firoja Blue and Siemens Gray/ As per re |

Company Details

Focusing on a customer-centric approach, PRAJAKTA ENGINEERS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Machineries in bulk from PRAJAKTA ENGINEERS at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

10

Establishment

2012

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Kolhapur, Maharashtra

Accepts only Domestic inquiries

Proprietor

Mr. Prafull Dhanpal Wardhamane

Address

Unit No. 14, Sai Nagar, Uchgaon, Kolhapur, Maharashtra, 416005, India

double spindle machine in Kolhapur

Report incorrect details