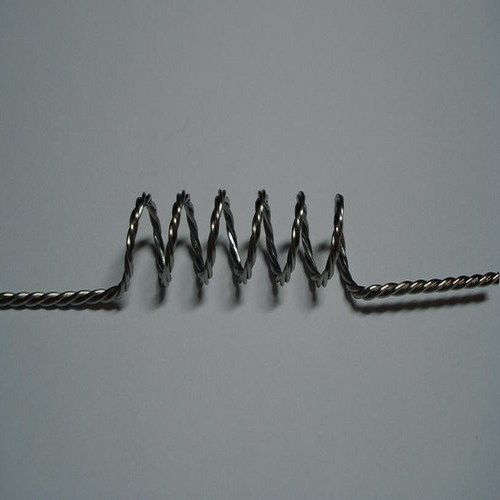

Blue Tungsten Rhenium Resistance Wire

Price Trend: 10.00 - 15.00 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| FOB Port | Shanghai |

| Delivery Time | 5 Days |

| Sample Available | Yes |

| Sample Policy | Within a certain price range free samples are available |

| Packaging Details | Plastic bag inside and carton outside |

| Main Domestic Market | All India |

Product Overview

Key Features

The wires is solid round smooth and be free of weld joints slivers kinks pits or nicks exceeding 5 % of diameter . Tungsten rhenium wire surface is uniformly clean and free of discoloration. The thermo elements is heat treated to provide the specified ductility.

Tungsten rhenium wire is used for heating elements in high temperature furnaces thermocouples and in electronics. Its advantage is its ability to maintain greater ductility compared to tungsten after exposure to extremely high temperatures. Tungsten wire has fiber structure when the temperature reaches 1500-1600a the tungsten filament would turn and cause high-temperature sag. To improve the quality of tungsten wire it is always mixed some additives during sintering procession such as Na2O K2O SiO2 ThO to enhance the capacity of high-temperature creep resistance and high temperature anti-sag of tungsten wire. In order to improve the tenacity of tungsten wire and prevent the deformation under high temperature it usually added some oxides such as silica alumina potassium and so on.

Tungsten rhenium wire is the most common material used to produce heaters for dispenser cathodes. Performance variation may be attributable to a range of factors including cold work and rhenium content variation.

Specification:

Tungsten rhenium wire main specifications are : W-Re1%i W-Re3%i W-Re5%i W-20%ReW-25%RW-26%Re.

Positive thermo element:

The positive thermo element A for the W3RE/W25RE combination have a nominal composition of 97 % tungsten and 3 % rhenium.

The positive thermo element A for the W5RE/W26RE combination have a nominal composition of 95 % tungsten and 5 % rhenium.

The positive thermo element is doped by the addition of potassium silicon and aluminum compounds or otherwise Stabilized by the addition of volatile substances that promote desirable grain structure and workability and maintain ductility after high temperature use.

Negative thermo element:

The negative thermo element for the A W3RE/W25RE combination have a nominal composition of 75 % tungsten and 25 % rhenium.

The negative thermo element for the A W5RE/W26RE combination have a nominal composition of 74 % tungsten and 26 % rhenium.

Diameter: 0.1-1.1mm

Common Uses: Due to its excellent physical properties our high-performance Tungsten Rhenium wire could be used as resistance wire in special fieldscathode filamention source wire and surgical probe used in medical field

Tips of Tungsten Rhenium Wire Use:

A. The positive pole is either WRe3 or WRe5; the negative pole is either WRe25 or WRe26

A. Temperature point: When the cold junction temperature is at 0 the temperature of the hot junction is at 000; the EMF value of the I 0.1mm wire is calibrated at the Palladium(Pd) melting point let q(Pd)=1554we use purity Platinum melting point to calibrate theI 0.1mm wire in a form test let q(Pt)=1769.

A. Uniformity: the non-uniform electromotive force of the single pole thermocouple wire from head to heel should a A 40 mv at 1200.

A. Ductility: After stable anneal the thermocouple wire can wrap itself six circles without cleavage.

A. Supply condition: the thermocouple wire is supplied after stable anneal its silvery white color.

A. Hot junction weld: Make the positive and negative pole of the wire in order use forceps to nip the wire and heating upon an alcohol burner. After twisting 3-5 circles use an argon arc to weld into a ball shape.

Related Products

More Product From This seller

Company Details

Business Type

Manufacturer, Supplier

Employee Count

100

Establishment

1984

Working Days

Monday To Friday

Explore Related Categories

Seller Details

Wuxi, Jiangsu

Sales Manager

Mr Eric

Address

No.18 Nanxin 2nd Road Xinwu District Wuxi Jiangsu 214000 China

corrosion resistant wire in Wuxi

Report incorrect details