- Tradeindia

- Shredding Machine

- Mobile Crushers

Mobile Crushers

(148 products)Steel Industrial Static Crusher

Price: 1800000 INR/Unit

MOQ10 Unit/Units

General UseIndustrial

MaterialSteel

AutomaticYes

Control SystemManual

Wheel Type Mobile Crusher Mobile Jaw Crusher for Mining Quarry

Price: 12500.0 USD ($)/Set

MOQ1 Set/Sets

Product TypeStone Crusher

General UseStone Crusher

Capacity90-180 t/h T/hr

ComputerizedYes

CNC Or NotCNC

Control SystemPLC Control

Yellow Mobile Stone Crusher

Price: 4000000 INR/Piece

MOQ1 Piece/Pieces

ColorYellow

Weight5000 to 10000 Kilograms (kg)

UsageRoad construction work, metallurgical, construction

ConditionNew

MaterialMild Steel

Power SourceElectric

Yellow Mobile Jaw Crusher 200 Tph

Price: 4500000 INR/Piece

MOQ1 Piece/Pieces

ColorYellow

Product TypeJaw Crusher

MaterialMild Steel, Other

Capacity200 T/hr

ComputerizedYes

AutomaticYes

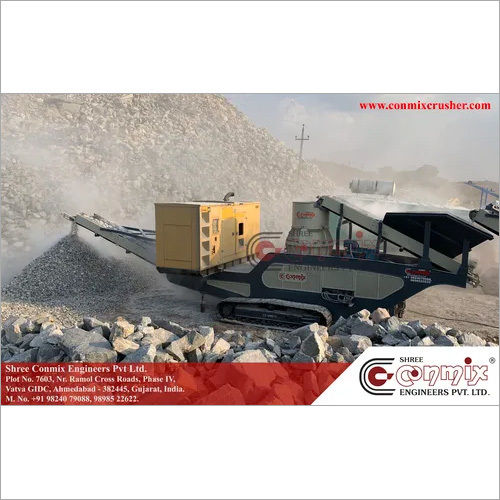

Mobile Crusher

Price: 5500000 INR/Unit

MOQ1 Unit/Units

Product DescriptionMobile Crusher

Semi-Automatic Mobile Crusher Machine

Price: 6300000 INR/Unit

MOQ5 Unit/Units

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

CNC Or NotNormal

Power SourceElectricity

Mobile Crusher Plant - Color: Gray

Price: 450000 INR/Unit

MOQ1 Unit/Units

ColorGray

Product TypeMobile Crusher Plant

General UseIndustrial

AutomaticNo

Control SystemPLC Control

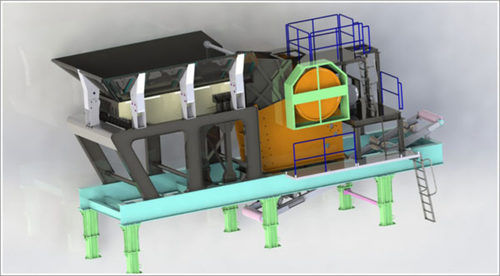

Mobile Crushing Station - Advanced Design with Superior Grade Components | Sturdy, Robust, Low Maintenance

MaterialSteel

DimensionsVariable

WeightVariable

PowerVariable

CapacityVariable

FeaturesHigh Capacity, Easy Operation, Low Maintenance, Durable Design, Robust Build, Superior Quality, Efficient Crushing, Portable Unit

Low Noise Industrial Slow Silent Crusher

Price: 275000 INR/Unit

MOQ1 Unit/Units

FeatureHigh Performance, Low Noise, Lower Energy Consumption, High Efficiency

Mobile Crusher - High Efficiency Portable Crushing Equipment , Integrative All-in-One Design with Convenient Maintenance and Flexibility

Weight100 Tons

Dimensions20X10X8 M

EngineCummins 450Hp

MaterialsSteel, Rubber

Capacity500Tph

Crusher TypeJaw, Cone

ZY-1 Coarse Mobile Crusher

Price: 1000 USD ($)/Piece

MOQ1 Piece/Pieces

MaterialMild Steel

Automatic GradeAutomatic

Top Rated Products

FAQs Related to Mobile Crushers

Who are the top mobile crushers manufacturers in India?

- Vindhya Engineering

- Roljack Asia Limited

- Karan Engineering Co.

- Shivam Construction Company And Earth Movers

- Henan Tomings Machinery Co Ltd

Which cities have the largest number of mobile crushers suppliers?

- Delhi

- Chennai

- Pune

- Bengaluru

- Hyderabad

- Kolkata

- Jaipur

- Coimbatore

- Ahmedabad

- Faridabad

- Thane

- Ghaziabad

- Vadodara

- Gurugram

- Udaipur

- Gandhinagar

- Indore

- Muzaffarnagar

- Tirupur

- Zhengzhou

How many trusted sellers are available for mobile crushers?

- SHIVAM CONSTRUCTION COMPANY AND EARTH MOVERS

- HENAN TOMINGS MACHINERY CO LTD

What is the minimum order quantity for mobile crushers?

Do listed companies have registration & certifications?

- Vindhya Engineering

- BHP Infrastructure Pvt. Ltd.

- Jinan YZH Machinery Equipment Co., Ltd.

What is the get latest price feature?

What types of payment methods are accepted by the mobile crushers suppliers?

Secondary Cone Mobile Crusher

Weight25000Kg

Dimensions12X4X3M

Engine250Hp

MaterialSteel

Capacity150Tph

Crusher TypeCone

Henan Liming Heavy Industry Science And Technology Co. Ltd

Zhengzhou

Ac Motor Track Mounted Mobile Vertical Shaft Impector

Price: 1000000 INR/Unit

MOQ01 Unit/Units

ColorRAL

TypePortable Vertical Shaft Impactor

MaterialSteel

Crusher TypeOther

ComputerizedYes

Automatic GradeAutomatic

Hydraulic Mobile Cone Crushers with Adjustable Function

MaterialSteel

DimensionsVariable

CapacityVariable

PowerVariable

WeightVariable

Crusher TypeCone

Mobile Crusher - 50-400 Tph Capacity | Customizable Durability and Quality Assurance

MaterialSteel

DimensionsVariable

Capacity50-400 Tph

EngineElectric Motor

WeightHeavy-Duty

PowerHigh Powered

Stationary Type Pedestal Hydraulic Rock Breaker Booms System Body Material: Stainless Steel

Price: 390000 USD ($)/Set

MOQ10000 Set/Sets

Weight6500 Kilograms (kg)

Size1

Product TypeYZH

UsageIndustrial

Width1 Meter (m)

ColorRed

Lime Calcination Plant

MaterialHigh-Strength Steel

DimensionsVariable

CapacityVariable

PowerVariable

WeightVariable

Jaw SizeVariable

Tracked Mobile Reaction Crushing Station - Medium to Large Capacity | Versatile Crushing & Screening Functions with Disassemblable Sieve Box

MaterialSteel

DimensionsVariable

WeightHeavy Duty

EnginePowerful

CapacityHigh Volume

PowerElectric/Diesel

Custom Impact Crusher For Limestone

Product TypeCustom Impact Crusher For Limestone

AutomaticYes

Track Mounted Mobile Crushers

Engine Power150 Hp

Crushing Capacity150 Tph

MaterialSteel

Dimensions12X5X4 M

Weight30000 Kg

TracksSteel

Durable Mobile Crusher Machine - Mild Steel Body, 20 Ton/hr Capacity | Eco-Friendly, Low Noise, Lower Energy Consumption

MOQ10 Piece/Pieces

Product TypeDurable Mobile Crusher Machinec

FeatureLower Energy Consumption, ECO Friendly, Low Noise

Mobile Crusher - Versatile Asphalt and Concrete Crushing Machine | Tertiary, Secondary and Primary Particle-On-Particle Crushing, Enhanced Material Quality

MaterialSteel

DimensionsVariable

PowerVariable

CapacityVariable

WeightVariable

Crushing TypeImpact

Industrial Mobile Jaw Crushers

MaterialSteel

DimensionsVariable

WeightVariable

EngineDiesel

CapacityVariable

Jaw SizeVariable

Mining Mobile Crusher

Feeding Size400-1520 Mm

Production Capacity50-250 T/H

Discharge Opening Size65-275 Mm

MaterialSteel

DimensionsVariable

WeightHeavy

Primary Mobile Crusher

Capacity30Kg, 50Kg

Accuracy2G, 5G

Pan Size350X350Mm

MaterialSteel, Plastic

DisplayDigital

PowerAc Adapter

Mobile VSI Crusher

MaterialSteel

DimensionsVariable

CapacityVariable

PowerVariable

WeightVariable

EngineDiesel

Latest from Mobile Crushers

Mobile Sand Making And Crushing Station For Quarry Coal Construction Waste Mobile Crusher

7097500 INR

By:

Henan Tomings Machinery Co Ltd

Mini Mobile Crusher

By:

Himanshi Engineers

Combination Mobile Crusher For Industrial Usage

By:

Henan Liming Heavy Industry Science And Technology Co. Ltd

Efficient Quality Mobile Crushers

By:

Mewar Hitech Engineering Ltd.

Industrial Tracked Mobile Crusher

By:

Shanghai Dingbo Heavy Industry Machinery Co., Ltd.

Ready To Ship Mobile Crushers

Why Are Mobile Crushers Exceptionally Better Aggregate Production Machines?

Mobile Crushers are derivable crusher machines mounted on tracks, most extensively used for aggregate production. Easy to move on and between the construction and mining sites, these mechanical beasts have exceptional crushing power to break down giant rocks. These are hired across various industries including recycling, mining, construction, etc. in place of stationary crushing machines, to reduce overall operational costs.

Benefits of Mobile Crushers

-

Versatility

Mobile Crushers are highly versatile mechanical equipment that can be used for various worksites with flexible operations, rough terrain, and harsh environments including construction project sites, quarries, demolition grounds, etc.

-

Time and Cost Efficiency

Movable crushers eliminate the waste of time and money it takes to transport the machinery between sites, the materials to the stationary crusher, etc. Overall mobile crusher saves operational costs and enhances productivity saving time.

-

Enhanced Productivity

Mobile crushers, no matter on which project they are hired for, improve the productivity levels by many folds. They are built for a rigorous environment and continuous working hours with no downtime. This results in increased productivity because of material processing capacity.

-

On-Site Crushing

Mobile Crushers facilitate the on-site crushing of various materials and reduce the transportation cost of moving the materials to a stationary crusher. The moveable feature of mobile crushers makes it very clear to achieve the project timeline.

-

Environmental Benefits

Mobile crushers equipped with advanced technologies, such as hybrid or electric power options, reduce emissions and environmental impact compared to traditional diesel-powered crushers.

-

Accessibility to Remote Areas

Mobile crushers provide access to remote or hard-to-reach locations, enabling efficient processing of materials in areas where stationary crushers may not be feasible.

-

Customization Options

Mobile crushers come in various configurations and sizes to suit different applications and material types, offering customization options to meet specific project requirements.

-

Versatile Crushing Capabilities

Mobile crushers can handle a wide range of materials, including concrete, asphalt, rock, and natural aggregates, making them suitable for diverse applications in the construction, mining, and recycling industries.

-

Safety

Mobile crushers are equipped with safety features such as remote control operation, overload protection, and automatic shutdown systems, ensuring safe and efficient operation for operators and workers.

-

Adaptability

Mobile crushers offer adaptability to changing production demands, allowing for easy adjustment of crushing parameters and configurations to optimize performance and output.

Applications of Mobile Crushers

-

Construction

Mobile crushers are used for on-site crushing of construction waste, including concrete, bricks, asphalt, and demolition debris, transforming them into reusable materials for road construction, building foundations, and landscaping.

-

Mining

In mining operations, mobile crushers are employed for the primary crushing of ore, coal, and minerals, reducing large rocks into smaller fragments for further processing in downstream operations such as milling and beneficiation.

-

Quarrying

Mobile crushers are utilized in quarrying operations to crush and screen various types of rock, stone, and aggregates, producing materials for construction, road building, and concrete production.

-

Recycling

Mobile crushers play a vital role in recycling operations by crushing recycled materials such as concrete, asphalt, and demolition waste into reusable aggregates and materials for construction and manufacturing applications.

-

Road Construction

Mobile crushers are used to process materials directly at road construction sites, crushing rocks, gravel, and aggregates to produce base materials for road foundations, asphalt paving, and concrete construction.

-

Landscaping

Mobile crushers are employed in landscaping projects to crush and process rocks and aggregates for creating pathways, retaining walls, and decorative features in parks, gardens, and public spaces.

-

Demolition

Mobile crushers are utilized in demolition projects to crush and process concrete, bricks, and other building materials, facilitating the removal and recycling of demolition waste from construction sites.

-

Aggregate Production

Mobile crushers are used in aggregate production facilities to crush and screen raw materials such as gravel, sand, and rock, producing various sizes and grades of aggregates for construction and infrastructure projects.

-

Portability

Mobile crushers are ideal for temporary or remote construction projects, mining operations, and quarrying sites where stationary crushers may not be feasible, providing portable crushing solutions for on-demand material processing.

-

Environmental Remediation

Mobile crushers are employed in environmental remediation projects to crush and process contaminated soil, concrete, and debris, facilitating site cleanup and restoration efforts in polluted areas.

How to Choose a Mobile Crusher For Yourself?

-

Identify Your Application

Determine the primary purpose of the crusher, whether it's for crushing aggregates, recycling materials, processing minerals, or other specific applications like demolition or landscaping.

-

Evaluate Crushing Capacity

Assess the required crushing capacity in terms of tons per hour or cubic meters per hour to ensure the chosen crusher can handle the anticipated production demands.

-

Consider Material Characteristics

Take into account the type, size, hardness, and moisture content of the materials you'll be processing, as different crushers are designed to handle specific material properties.

-

Understand Mobility Requirements

Determine the mobility requirements of your project, considering factors such as site accessibility, terrain conditions, and the need for frequent relocation. Choose between track-mounted or wheeled mobile crushers based on mobility needs.

-

Review Size and Configuration Options

Evaluate the size, configuration, and features of available mobile crushers, including jaw crushers, impact crushers, cone crushers, and compact crushers, to find the most suitable option for your application.

-

Consider Power Source

Decide between diesel-powered, electric-powered, or hybrid mobile crushers based on factors such as fuel availability, emissions regulations, operating costs, and environmental considerations.

-

Assess Operational Features

Evaluate operational features such as crusher settings, feed size capacity, and discharge settings to ensure the crusher can produce the desired output size and quality.

-

Check Maintenance and Serviceability

Consider ease of maintenance, access to worn parts, and availability of service and support from the manufacturer or dealer to minimize downtime and ensure smooth operation.

-

Factor in Safety Features

Prioritize safety features such as remote control operation, overload protection, and safety interlocks to protect operators and workers during crusher operation and maintenance.

Mobile Crushers Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Vindhya Engineering Indore, India | 8 Years |

Roljack Asia Limited Udaipur, India | 7 Years |

Karan Engineering Co. Bhuj, India | 6 Years |

Shivam Construction Company And Earth Movers Rohtak, India | 3 Years |

Henan Tomings Machinery Co Ltd Zhengzhou, China | 2 Years |

Upcoming Tradeshows

IFSEC INDIA 2025

Thu, 11 Dec, 2025 - Sat, 13 Dec, 2025

China International Equipment & Manufacturing Industry Expo (CIEX) 2026

Wed, 18 Mar, 2026 - Sat, 21 Mar, 2026

INDIAN ICE CREAM CONGRESS & EXPO 2025

Mon, 06 Oct, 2025 - Wed, 08 Oct, 2025

Renewable Restart Energy India Expo 2025

Fri, 22 Aug, 2025 - Sun, 24 Aug, 2025

Auto EV Bharat 2025

Wed, 19 Nov, 2025 - Fri, 21 Nov, 2025

CPHI & PMEC China 2025

Tue, 24 Jun, 2025 - Thu, 26 Jun, 2025

WATER EXPO Bangalore 2025

Thu, 19 Jun, 2025 - Sat, 21 Jun, 2025

WORLD OF HOSPITALITY EXPO 2025

Thu, 12 Jun, 2025 - Sat, 14 Jun, 2025

MachAuto 2025

Fri, 25 Jul, 2025 - Mon, 28 Jul, 2025

Asia Labex 2025

Wed, 11 Jun, 2025 - Fri, 13 Jun, 2025

Popular Categories