Tcu Temperature Control Unit - 700x800x1650 Cm, 100l Max Capacity, Tube Heat Exchanger, -120 To 300 Degrees Temperature Control, Energy Efficient Design

Price Trend: 10000.00 - 30000.00 USD

Get Latest Price

Minimum Order Quantity :

One

In Stock

Product Specifications

| Max. Capacity | 100L Liter (L) |

| Condition | New |

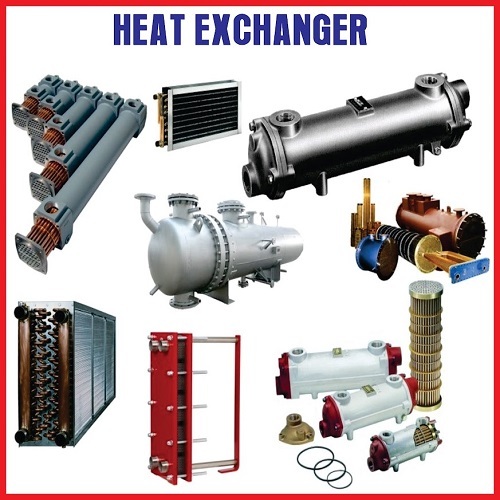

| Structure | tube Heat Exchanger |

| Working Presssure | 380V |

| Voltage | 380V Watt (w) |

| Power | 1.6kwi1/4^max) Watt (w) |

| Weight | 58 Kilograms (kg) |

| Dimensions | 700*800*1650 Centimeter (cm) |

| FOB Port | Wuxi |

| Payment Terms | Letter of Credit (L/C), Western Union, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T) |

| Supply Ability | 5 Per Month |

| Delivery Time | One Months |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | New |

| Main Export Market(s) | North America, South America, Eastern Europe, Western Europe, Central America, Asia |

| Main Domestic Market | All India |

| Certifications | IOS9001,CE |

Product Overview

Key Features

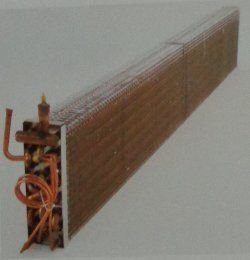

The existing thermal energy infrastructure(e.g. steam, cooling water and ultra-low temperature liquids-the "primary system") is integrated into a single-fluid system or secondary loop used to control the temperature of the process equipment. This completes the flow of only one heat-conducting liquid into the jacket of the reaction vessel(rather than directly into steam, cooling water or ultra-low temperature liquids). The temperature of the whole reaction process is controlled by operation.

The use of a single-fluid heat transfer temperature control system has the following advantages:

A, the user can obtain a closed, repeatable temperature control in a wide temperature range, can achieve -120 degrees to 300 degrees temperature control;

B, avoiding the replacement of traditional equipment facilities and the need for jacket maintenance; The smaller fluid volume also ensures the rapid reaction of the control loop and the thermal reaction delay is very small;

C, built-in electric heating oil auxiliary system, can automatically open the auxiliary heating system according to demand, reduce the steam pressure;

D, you can achieve energy conservation by running fast and accurately to match the demand for each heat;

Company Details

Business Type

Exporter, Manufacturer, Supplier, Retailer, Dealer

Employee Count

100

Establishment

2011

Working Days

Monday To Saturday

Payment Mode

Telegraphic Transfer (T/T)

Certification

IOS9001

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Wuxi, Jiangsu

Proprietor

Ms Zhang

Address

No.203, Hongyun Road, Hongshan Street, Optoelectronics Park, Xinwu District, Wuxi, Jiangsu, 214000, China

industrial heat exchanger in Wuxi

Report incorrect details