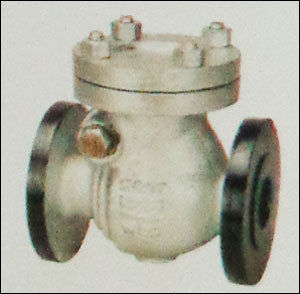

Swing Check Valves Our experience and great efforts in this domain has enabled us in marking a reputable position for manufacturing Swing Check Valves. Available in different specifications all these check valves are used for regulating flow of liquid in pipeline. All these valves are highly praised among our clients for their rugged construction durability and corrosion resistant surface. We supply our stock of Swing Check Valves to major industries like chemicals fertilizers and feed water. Further Details Design features: The body is designed for strength to meet operating conditions and contoured to minimize erosion and resistance to flow. The disc is opened and sustained in open position by the Velocity pressure of the fluid and closed by the force of gravity. Seating load and resultant tightness is aided by back pressure in the line. The body seat-ring is seal-welded to the body avoiding leakage in the path between the seat ring and the body. The seating surfaces are ground and lapped. Applications: Petroleum Power Generation Steel Industries and Effluent Treatment Plants Operators: Automatic/Hydraulic Damper/Counter Weights. Material Size Range Construction ANSI Class Standard Cast Carbon Steel / Cast Aloy Steel 2" - 20" Bolted or Pressure Sealed 150# - 2500# BS 1868 API 6D. Cast Stainless Steel 2" - 20" Bolted or Pressure Sealed 150# - 2500# BS 1868 API 6D. Bronze 2" - 8" Bolted Bonnet 150# - 600# BS 1868 API 6D Temperature range: -100oC to 600oCPressure Rating: Vacuum upto 621 Kg/Cm2Mfg Standard: BS1868End to End Dimension: ANSI B16.10Inspection Std.: API 598/BS 6755Ends: Flanged/ButtweldFurther DetailsA Swing Check Valve or tilting disc check valve is check valve in which the disc the movable part to block the flow swings on a hinge or trunnion either onto the seat to block reverse flow or off the seat to allow forward flow.