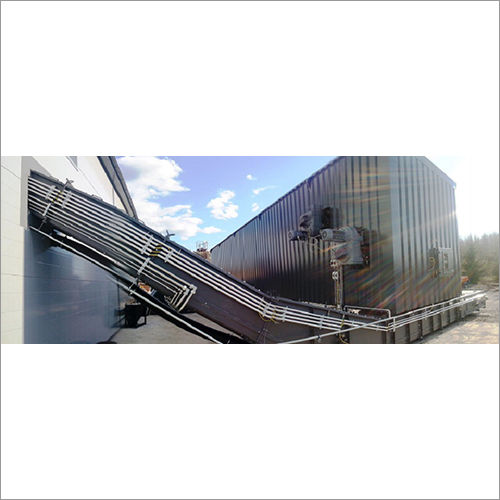

Submerged Scrapper Conveyor (Demech 0.03 M/s 400 Bhn)

Price:

Get Latest Price

In Stock

Product Specifications

| Payment Terms | Cash in Advance (CID), Cheque |

| Main Domestic Market | All India |

Product Overview

Key Features

SSC is a double strand chain conveyor for handling high temperature materials, which drops in the water which the conveyor is filled with. The chain strands are submerged in water and moves at very low linear speed of about 0.03 m/s and scraps out the material from the water.

There can be two variants in SSC depending on top or bottom chain action as the material conveying member. In the first one where the top chain conveys the material, has the return inactive chain outside the water filled chamber. The other variant where the bottom chain does the conveying activity has both the chain paths submerged in water.

The surface over which the chain scraps off the material is lined with hard material like Cast Basalt tiles or plates of 400 BHN hardness. The chains are either forged round link chains or drop forged machined chains.

A major part of SSC is the cooling water system. The water is maintained at a constant level in the conveyor chamber which is also used to air lock the furnace internals against atmospheric pressure by dipping the inlet in this water. The quantity of flow of cooling water to the conveyor is calculated based on the temperatures and flow rate of the material. The excess water is allowed to overflow from the conveyor through simple trap separator or a parallel plate separator. The overflowing water can be re-used after cooling it or drained off as per customer's requirement.

Application :

Handling Bottom Ash of coal fired boilers or any solid fuel fired boiler. The Economizer Ash and Coal Mill rejects if dumped in the SSC used for Bottom Ash will also be then removed.

To handle hot Kiln Dust of Direct Reduced Iron (DRI) plants.

Features:

DEMECH designs and supplies tailor made custom designed to suit customer's requirement of material handling rates and layouts.

Cast basalt lining to suit requirement is possible as it is an in-house item.

Long term collaboration agreement with Hitachi Power Europe GmbH ensures knowledge of best design engineering and new developments taking place to give better systems.

Scraper Chain Conveyors

For handling high temperature materials, which are quenched and dewatered

For handling coal ash, steel plant dust and sponge-iron plant dust etc.

Can be designed for special applications such as variable speed drive, flood feed conditions

Can be provided with Screw take up, spring take up or Hydraulic tensioning unit

Chains selected for prolonged life considering arduous working conditions

Special lining e.g. Cast Basalt, Tiscral, SS can be provided for specific applications

Mixer Conveyors

Combines the functions of mixing & conveying in a single machine

Intimate mixtures of multiple solids or solid and liquid are possible

Various capacity ranges are available.

Company Details

Focusing on a customer-centric approach, Deccan Mechanical & Chemical Industries Pvt. Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Get Conveyor & Conveyor/Industrial Belts from Deccan Mechanical & Chemical Industries Pvt. Ltd. at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

300

Establishment

1985

Working Days

Monday To Sunday

GST NO

27AAACD7365G1ZL

Related Products

Explore Related Categories

Seller Details

GST - 27AAACD7365G1ZL

Bhosari, Maharashtra

Marketing Manager

Mr. Sunpreet Singh

Address

Plot No-78, Bhosari Industrial Estate, MIDC, Bhosari, Bhosari, Maharashtra, 411026, India

wet scrapper conveyor in Bhosari

Report incorrect details