Steam Jet Ejector By G. S. Equipments

Price:

Get Latest Price

In Stock

Product Specifications

| Materials | Cast Iron, Mild Steel, Stainless Steel |

| Dimensions | Variable |

| Pressure range | 30-200 PSIG |

| Stages | Single or Multi-stage |

| Nozzles | Stainless Steel |

| Condenser type | Surface or Direct Contact |

| Suction pressure | Atmospheric to 3 inch Hg abs |

| Features | High vacuum, Simple design, Low maintenance, Cost effective, Versatile applications, No moving parts, Durable materials |

Product Overview

Key Features

Steam Jet Ejector

We are engaged in manufacturing superior quality range of Steam Jet Ejectors to our esteemed customers. Jet Pumps are a class of pumps in which the kinetic energy of a motive fluid is converted into pressure energy.

APPLICATIONS

High Vacuum Distillation

Deodorization

Deaeration

Bleaching

Evaporation

Crystallization

Drying of Solids

Filteration

Removal of Air & Gases

Liquid Handling

Steam Jet Refrigeration

Dairy Plants

Soap Plants

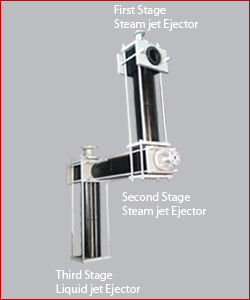

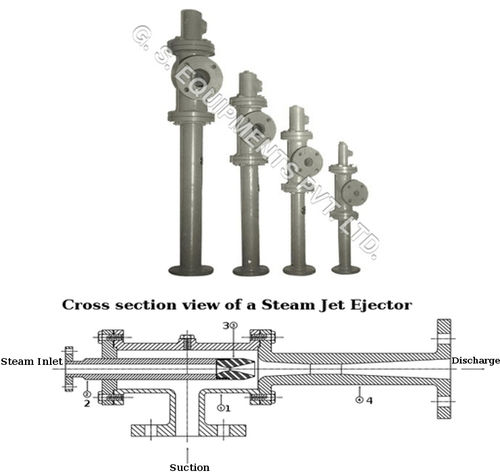

The Figure above shows cross section view of a Steam Jet Ejector.Steam is used as motive fluid and is allowed to pass through a nozzle holder (2) which further expands through a converging-diverging Nozzle (3) to emerge out with a high velocity.The suction fluid which may be Air,Water Vapours,Gases or any other fluid including liquid enters the suction port (1), mixes with motivating fluid and recompressed through the diffuser (4) losing kinetic energy & gaining pressure energy until at the diffuser outlet the desired degree of compression is achieved.The vapors finally coming out of the diffuser may either be discharged to atmosphere or into any other system.

These types of pumps can be designed for any motive or operating fluid,which may be steam,water,compressed air or any other gas or liquid. These type of ejector systems are inexpensive and matchless in simplicity.No maintenance is required over a long period of time as there are no moving parts.

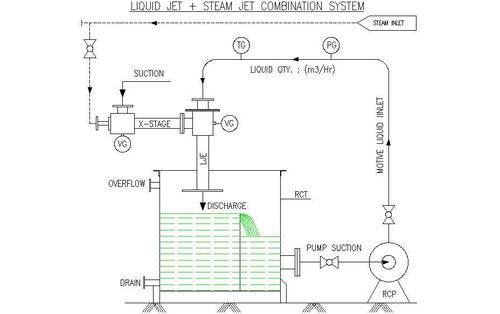

Generally Ejectors are furnished with various combinations of either the surface or direct contact type barometric condensers.Direct Contact type condensers are relatively compact,cheap and trouble free.They are applied where the mixing of condensate and cooling water may be permitted.A

barometric leg about 36 ft. long is required.Low level mounting is possible but relatively expensive.When the condensate recovery is essential or less head room is available,surface condenser may be used. Steam Jet Ejectors are normally designed to operate between 30 PSIG & 200 PSIG.Sometimes stages delivering against sub atmospheric pressure may be designed to operate at as low as 12 PSIG steam pressure.In such cases mostly a vacuum pump is incorporated as the last stage discharging to atmosphere. Normal range for a Single Stage Steam Jet Ejector is from atmospheric to 3 inch Hg abs.For lower suction pressures multi stage ejector systems are used,which may be of condensing or non condensing type.Steam consumption in a non condensing type unit is higher than the condensing type.A two stage non condensing unit will consume appx.80% higher steam than the condensing type unit for the similar application. Stainless Steel is normally used for Nozzles for long life & providing maximum resistance to steam erosion.Ejector bodies are normally of Cast Iron and Mild Steel.For corrosive services,any suggestive corrosive resistant material can be used like Stainless Steel etc.

Company Details

Focusing on a customer-centric approach, G. S. EQUIPMENTS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Vacuum Equipment & System in bulk from G. S. EQUIPMENTS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

5

Establishment

1981

Working Days

Monday To Sunday

GST NO

07AAOPS1696J1ZY

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AAOPS1696J1ZY

New Delhi, Delhi

Director

Mr. Pradeep Sharma

Address

BNo. D-III/3034, GF, VASANT KUNJ New Delhi, Delhi, 110070, India

Report incorrect details