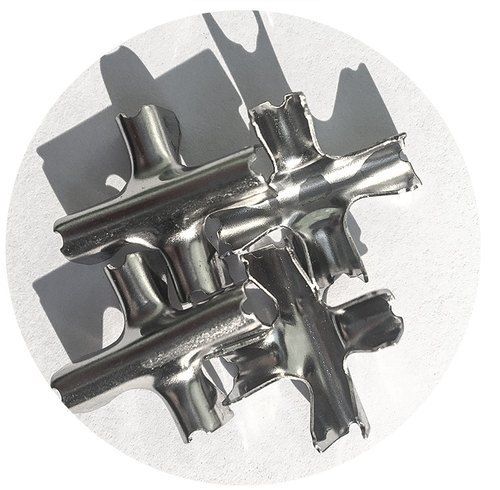

Stainless Steel Coils - Austenitic Grades 301/304/316/201/202/420/430 | Superior Corrosion Resistance, High Ductility, Excellent Weldability

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless steel |

| Dimensions | Various |

| Finish | Polished |

| Grade | 301/304/316/201/202/420/430 |

| Shape | Coils, circles, tubes, sheets |

| Thickness | Various |

| Width | Various |

| Features | Corrosion resistance, High strength, Durable, Versatile, Easy to fabricate, High temperature resistance, Low temperature resistance, High luster |

Product Overview

Key Features

WE ARE RETAIL SUPPLIER OF STAINLESS STEEL COILS CIRCLES TUBES AND SHEETS IN GRADES 301/304/316/201/202/420/430.

Austenitic Stainless Steel grades are characterized by superior corrosion and oxidation resistance, weldability, ductility and toughness compared to ferritic and martensitic Stainless Steel grades for similar levels of chromium. Austenitic Stainless Steel grades exhibit excellent resistance to atmospheric corrosion. They effectively withstand attack of organic acids (e.g. acetic, lactic, citric etc.), exhibit good resistance to oxidizing acids (e.g. nitric acid) and fair resistance to mineral acids (e.g. sulfuric acid). These grades are well suited for severe forming. Some grades work harden to a high degree while others have been developed to minimize this tendency. Work hardening is advantageous in certain cases where high strength is required. Austenitic Stainless-Steel grades are nonmagnetic in annealed condition but depending an composition, they may become mildly magnetic when cold worked. These Stainless Steel grades possess good high temperature properties such as creep strength and resistance to oxidation or scaling. They also exhibit excellent low temperature ductility and impact strength. Austenitic Stainless Steel grades can be readily fabricated by bending, drawing, spinning, punching, drilling, machining and welding and can be readily polished to a high finish. These attributes make them very versatile and popular to diverse applications in a variety of industries. There are two broad categories of Austenitic Stainless Steel a Chromea Nickel (300 Series) and Chrome Manganese (200 Series). Currently, Chrome-Nickel is the largest produced Stainless Steel category globally. Typical applications for this category include food processing, chemical plants, pharmaceutical equipment, hospitals, textile, architectural, building construction, kitchenware, consumer durables etc. Chrome-Manganese Stainless Steel is the fastest growing of all Stainless Steel categories on account of its high performance to cost ratio. Its applications include kitchenware, cutlery, sinks, automotive trim, architectural, buildings, furniture, buses, trains and ornamental tubes.

Martensitic Stainless Steel grades are plain chromium grades containing 11, 5% to 18% of chromium with relatively high carbon content (0, 1%-1, 2%). Initially developed for cutlery, these are well suited for applications requiring high hardness and resistance to abrasion and erosion. These grades are magnetic and display fair cold forming characteristics. Although these can be hardened by aircooling, oil quenching is sometimes used to assure uniform hardening. These grades can be welded but require stress relieving after welding. They exhibit their best corrosion resistance in the hardened condition and perform well in mildly corrosive environments. Martensitic Stainless Steel grades are commonly used for knife blades, turbine blades, surgical instruments, fasteners, shafts, spindles, valves and pins.

Ferritic Stainless Steel grades are non-hard enable plain chromium grades with chromium content varying from 10, 5% to 28% and with low carbon content. These are magnetic and exhibit a better resistance to corrosion than martensitic grades. These grades are employed in applications where the desired formability, weldability and corrosion resistance is between those of martensitic and austenitic types. The ferritic can be polished or buffed to achieve high luster.

Duplex Stainless Steel grades contain relatively high chromium (between 18% and 28%) and moderate amounts of nickel (1% to 8%). This combination of ferritic and austenitic structures is called duplex. Many of these grades contain molybdenum (1% to 5%) and nitrogen (0, 05% to 0, 3%).

Company Details

Focusing on a customer-centric approach, Pranama Steel Trading has a pan-India presence and caters to a huge consumer base throughout the country. Buy Metals & Alloys in bulk from Pranama Steel Trading at Trade India quality-assured products.

Business Type

Supplier, Trading Company

Employee Count

3

Establishment

2016

Working Days

Monday To Friday

GST NO

24CVOPK3426R1ZX

Payment Mode

Cash Against Delivery (CAD)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24CVOPK3426R1ZX

Ahmedabad, Gujarat

Business

Mr Mahesh Subhas Padmannavar

Address

FF/B, Ramrath Ind Coop Society, Near Muncipal Bus Stop Hatkeshwar Khokra CTM, Ahmedabad, Gujarat, 380008, India

stainless steel in Ahmedabad

Report incorrect details