Spd-v020 Multifunctional Strand Condition Monitor

Price:

Get Latest Price

In Stock

Product Specifications

| FOB Port | Shenzhen |

| Payment Terms | Western Union, Paypal |

| Supply Ability | 2000 Per Month |

| Delivery Time | 15 Days |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Export Market(s) | Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa |

Product Overview

Key Features

SPD-V020 Multifunctional Strand Condition Monitor

Overview

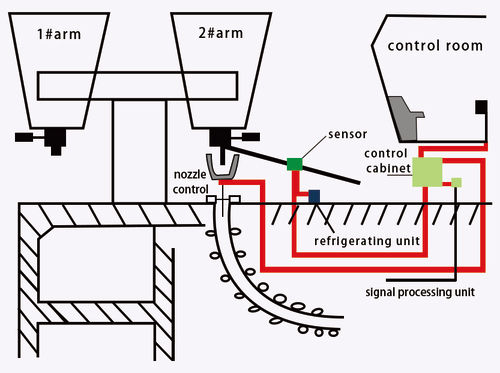

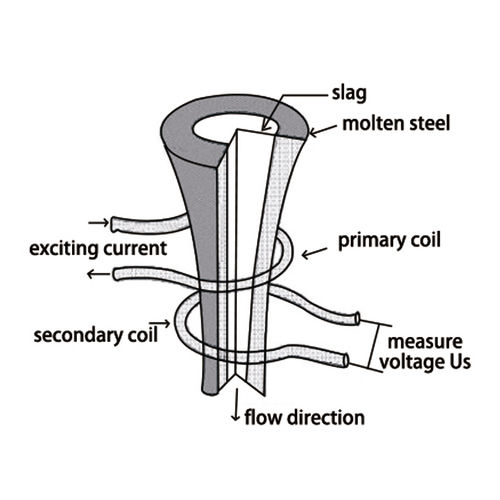

In the production process of the multifunctional strand condition monitor, in order to ensure the quality of the slab, it is necessary to strictly control the performance and various parameters of the CCMa s guide roll within a certain error range. Due to the continuous casting machine (CCM) is large and in a harsh production environment, it is difficult to measure the performance of the continuous casting machine manually, and many parameters are difficult to measure. Therefore, it is very important to have a set of equipment that can simulate drawing of steel billet to realize the measurement of CCMa s various parameters and performance. The multifunctional strand condition monitor uses various sensors to realize the measurement of CCMa s roll gap value, the arc value of continuous casting section, the rotation quality of the rolls, and the water spray pressure under the condition of simulating drawing of steel billet. Therefore, the CCMa s quality can be controlled in real time, and it is convenient for the maintenance personnel to analyze the CCMa s measurement results. The problem areas of the casting machine equipment can also be found. If these problems doesna t be found in time, it will cause the bad quality of CCMa s products, the steel breakout in pouring process, surface and internal cracks and centerline segregation.

The measurement of the strand condition monitor

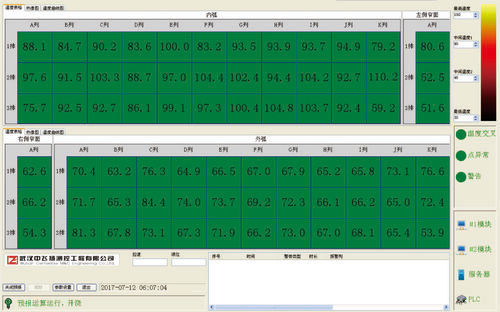

Roll gap valuei

By measuring the distance between a series of inner arc guide rolls and outer arc guide rolls on the CCMa s roller bed.

It can be used to set the correct roll gap spacing for each pair of guide rolls in the slab caster.

Outer arc guide roller to arci

By measuring the deviation between the position of the CCMa s outer arc guide roll and the two adjacent guide rolls and the CCMa s original position, we can obtain the arc condition of the outer arc guided roller.

Guided roller rotationi

It is possible to know whether each guided roller can rotate freely by measuring.

Water spray pressurei

The operation of the water spray cooling system can be judged by measuring the situation of secondary cooling water spray at different positions of CCM's width direction. Then we can accurately locate whether the water spray at a certain point is normal.

The main components of the strand condition monitor

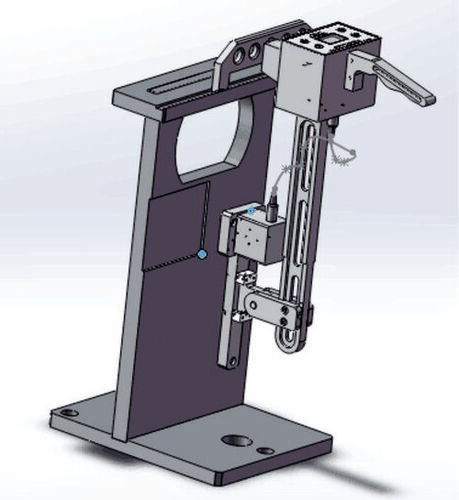

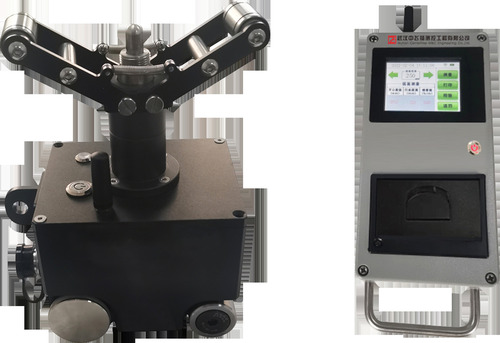

1. The main body of the strand condition monitor used to measure the continuous casting sector

2. The connecting chain between strand condition monitor and dummy bar

3. The storage rack chain of strand condition monitor

4. Battery charger: 24V 5A

5. Calibration equipment

6. Remote control

7. Laptop

8. Printer

9. Data communication cable

The technical parameter

1. The measurement range of roll gap: 210mm, 230mm (can be customized according to requirements)

2. The measurement accuracy of roll gap: 0.01mm

3. The arc measurement range: A 80A

4. The arc measurement accuracy: 0.01A

5. The spray measurement range: 0-10

6. The spray measurement accuracy: A 1

7. The battery usage times: >3 times

Overview

In the production process of the multifunctional strand condition monitor, in order to ensure the quality of the slab, it is necessary to strictly control the performance and various parameters of the CCMa s guide roll within a certain error range. Due to the continuous casting machine (CCM) is large and in a harsh production environment, it is difficult to measure the performance of the continuous casting machine manually, and many parameters are difficult to measure. Therefore, it is very important to have a set of equipment that can simulate drawing of steel billet to realize the measurement of CCMa s various parameters and performance. The multifunctional strand condition monitor uses various sensors to realize the measurement of CCMa s roll gap value, the arc value of continuous casting section, the rotation quality of the rolls, and the water spray pressure under the condition of simulating drawing of steel billet. Therefore, the CCMa s quality can be controlled in real time, and it is convenient for the maintenance personnel to analyze the CCMa s measurement results. The problem areas of the casting machine equipment can also be found. If these problems doesna t be found in time, it will cause the bad quality of CCMa s products, the steel breakout in pouring process, surface and internal cracks and centerline segregation.

The measurement of the strand condition monitor

Roll gap valuei

By measuring the distance between a series of inner arc guide rolls and outer arc guide rolls on the CCMa s roller bed.

It can be used to set the correct roll gap spacing for each pair of guide rolls in the slab caster.

Outer arc guide roller to arci

By measuring the deviation between the position of the CCMa s outer arc guide roll and the two adjacent guide rolls and the CCMa s original position, we can obtain the arc condition of the outer arc guided roller.

Guided roller rotationi

It is possible to know whether each guided roller can rotate freely by measuring.

Water spray pressurei

The operation of the water spray cooling system can be judged by measuring the situation of secondary cooling water spray at different positions of CCM's width direction. Then we can accurately locate whether the water spray at a certain point is normal.

The main components of the strand condition monitor

1. The main body of the strand condition monitor used to measure the continuous casting sector

2. The connecting chain between strand condition monitor and dummy bar

3. The storage rack chain of strand condition monitor

4. Battery charger: 24V 5A

5. Calibration equipment

6. Remote control

7. Laptop

8. Printer

9. Data communication cable

The technical parameter

1. The measurement range of roll gap: 210mm, 230mm (can be customized according to requirements)

2. The measurement accuracy of roll gap: 0.01mm

3. The arc measurement range: A 80A

4. The arc measurement accuracy: 0.01A

5. The spray measurement range: 0-10

6. The spray measurement accuracy: A 1

7. The battery usage times: >3 times

Company Details

Our business scope includes the research and development, production and sales of automation systems, devices and various instruments. We are an integrated automation company that designs and implements the control system and provides comprehensive automation systems and process control solutions.

Business Type

Manufacturer

Employee Count

50

Establishment

2007

Working Days

Monday To Friday

Payment Mode

Western Union

More Product From This seller

Seller Details

Wuhan, Hubei

Floria Liang

Address

Building 4, Hengxin Industrial Park, No. 8 Xinhua Avenue, Huangpi District, Wuhan, Hubei, 432200, China

Report incorrect details