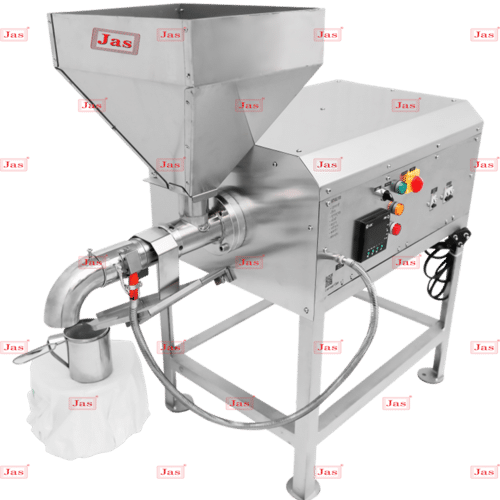

Automatic Soy Protein Isolate Machine

Price: 3000 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Type | Other |

| Material | Soybean Cake |

| Production Capacity | 30-500 Ton/day |

| Computerized | Yes |

| Automatic Grade | Automatic |

| Control System | PLC Control |

| Voltage | 220 Watt (w) |

| Color | Other |

| Warranty | 5 years |

| FOB Port | Qingdao |

| Payment Terms | Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA) |

| Supply Ability | 500 Tons Per Day |

| Delivery Time | 30 Days |

| Sample Available | Yes |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Export Market(s) | Australia, Central America, South America, Middle East, Africa, Asia |

| Main Domestic Market | All India |

| Certifications | ISO9001:2008, SGS, etc. |

Product Overview

Key Features

Soybean isolated protein is extracted from meal through successive processes. The product is a kind of milk white powder which contains protein content of more than 90%. SPI can be recombined with various food to improve and enrich food nutrition. SPI is a full price protein food additives, raw materials is low temperature desolventizing soybean meal. SPI contains about 20 amino acids, and contains the human body essential amino acids, protein content over 90%, and no cholesterol, is extremely rare in plant protein to replace one of the varieties of animal protein.

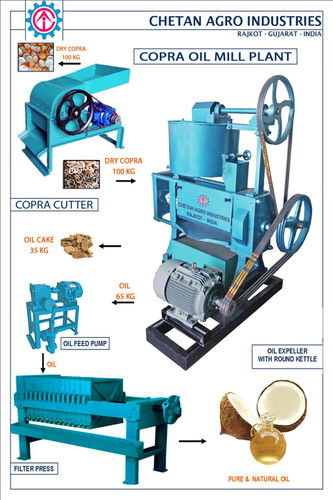

Oil seeds: soybean cake

Application: isolation of protein from extracted soybean cake

Description: SPI is a full price protein food additives, raw materials is low temperature desolventizing soybean meal. The production of soybean protein isolated is the use of the solubility of soybean protein significantly

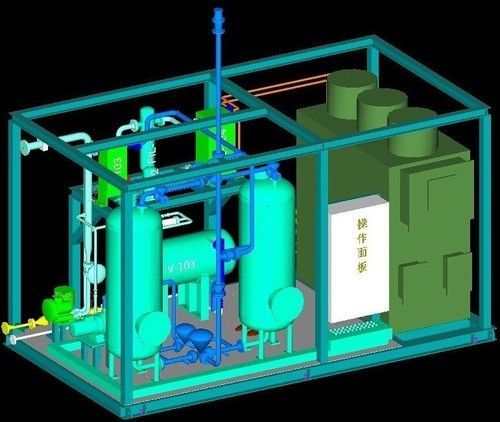

2.1 Extraction

Delivery the defatted soybean to the extraction workshop, weighing 600kg per batch hoisted into the first extraction groove by the electric hoist (101), hot water has been added in the tank advance, high speed stirring when feeding, stirring speed of 120 rev/min. Adding NaOH to adjust the pH value to 7.1, after reaction 5-10 minutes change to low speed stirring 60 rpm / min. Open the discharge valve for discharge, pump into the first extraction separator(104) by the first extraction conveying pump(103). The liquid phase flows into the mixed soy milk tank(108), and use hot water flush the solid phase to the second extraction groove(105).After second extraction, delivery the material into the second extraction separator(107) by the second extraction pump(106). The solid phase by the screw conveyer(110) send to the dregs storage stack, for sell, liquid phase flows into mixed soy milk tank(108), and mixed with the soy milk from the first extraction separator(104), then pumped them by the soy milk pump( 109) into acid precipitation tank(111) for acid precipitation.

2.2. Acid precipitation

Adding sodium metabisulfite (0.6kg per batch) to the acid precipitation tank for bleaching and reducing viscosity the mixed soybean milk, then adding HCL(35%), as well as higher the stirring speed to 120 rev/min, adjust the pH value to 4.5. Then reduce the stirring speed to 60 rev/min after acid precipitation. The discharge pump into acid precipitation separator(113) by the acid precipitation pump(112). Liquid flow out of the workshop from pipe, and the solid(curd) flush into the crshuing machine(114) by cold water, crushing and diluting, pumped into neutralization tank(116) by the curd pump(115).

2.3. Neutralization and sterilization

Adding NaOH(10%) into to neutralization tank(116) to neutralized the diluted curd, adjust the PH value to about 7.1. Adding cooling water in order to reduce the temperature of the neutralizing liquid to 15-20.

Neutralizing liquid(A liquid) transfer by the A liquid delivery pump(117), through the filter(118) then pressed by the high pressure pump,sterilized by the direct steam in the sterilizing device(120), sterilization temperature 140, last 15 seconds. After sterilization, the liquid(B liquid) enter into flash tank(121), vacuum degree is 600mmHg.Vacuum is obtained by the hydraulic ejector (143).

2.4. Drying and product packaging

B liquid spray into drying tower(201) under the high pressure, droplet of the B liquid contact with 145 hot air from the hot-blast stove(220), hot air amount: 33000Nm3/hr. the dried product with hot air(75) are separated in the cyclone separator (202), and the hot air is discharged into the atmosphere through draught fan (207).

The product from cyclone separator (202) enter into receiving hopper(204), then delivered to the bag filter(209) by the air flow, gas is discharged into the atmosphere by the conveying draught fan(210), The finished product to storage(212) from bag filter.

Company Details

Henan Huatai Cereals And Oils Machinery Co.,Ltd. was founded in 1950,whcih is a large-scale oil machinery manufacturing enterprise integrating R & D, design, manufacture and installation as one of the major grain and oil machinery manufacturing enterprises in China.Our company headquartered located in Huaxiang County Industries,Henan Province,China,covering 100,000.00 square meters. Huatai machinery has developed projects including large scale oilseed pretreatment and pressing, oil extraction, oil refining and oil fractionation production line project,conveyor equipment project,corn/maize flour, grits, germ milling machines and corn processing lines,biodiesel technology,cottonseed, rice bran and soybean protein technology, and Palm Oil processing lines,etc. One of the most largest Cooking oils factory in China. Production of grain and oil equipment solutions from A to Z. Huatai is a factory with more than 60 years experience. More than 100,000 square meters. Over 580 professional employees. 8 Large-scale workshop, 120 production equipments. Henan Huatai Cereals And Oils Machinery Co.,Ltd is committed to R&D of new efficient oil machines, manufacturing customer oriented oil machines, and leading the development direction of the world's most advanced grain processing machines and oil processing machines. We are reply on technology and innovation, constantly developing new type oil machines and equipment in order to achieve worlds advanced level.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

500

Establishment

1950

Working Days

Monday To Sunday

Certification

ISO9001, SGS

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Zhengzhou, Henan

Accepts only Foreign inquiries

Ms Ken Wang Wang

Members since

6 Years

Address

B26 No.1, Cuizhu Street High-Tech Zone, Zhengzhou, Henan, 450000, China

oil processing machinery in Zhengzhou

Report incorrect details