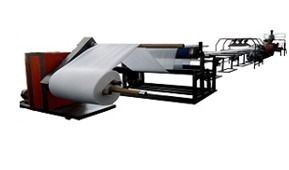

Solid Foam Silicone Calender Machinery - Solid Silicone, 2000x1800x1900 Mm, 450 Mm Max Diameter, 13 Kw Power, 15 M/min Roller Speed | Automatic Tension Control, Integrated Input Unit, Hollow Roller Heating System, Real-time Roller Gap Detection

Price: 60000 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Type | four roller calender machine |

| Material | solid silicone |

| Capacity | 10 Cubic Meter (m3) |

| Computerized | Yes |

| Automatic Grade | Automatic |

| Control System | PLC Control |

| Cooling System | Other |

| Rolller Speed | 15m/min. m/m |

| Max. Diameter | 450 Millimeter (mm) |

| Power Consumption | 13KW Kilowatt (kW) |

| Voltage | 380V Volt (v) |

| Weight | 3000 Kilograms (kg) |

| Dimension(L*W*H) | 2000*1800*1900 Millimeter (mm) |

| Warranty | 12months |

| FOB Port | SHA |

| Payment Terms | Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T) |

| Supply Ability | 10set/month Per Month |

| Delivery Time | 45days Days |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | sea worthy wooden box |

| Main Export Market(s) | Asia, North America |

| Main Domestic Market | All India |

| Certifications | CE,SGS,ISO,Etc. |

Product Overview

Key Features

Application Range

Ita s applicable to make various solid silicone, solid foam silicone, KE951 material, rubber material, thermal conductivity silicone material, silicone heating pad, silicone rubber self fusing tape material, LCD light shielding sheet material, seal material, silicone thermal insulation sheet material, ETC.

Features:

1, For the inputting unit, It is integrated into the overall machine, so, ita s easy operating and can save occupying space.

2, For tension control, it is automatically controlled by magnetic powder brake and tension controller, so the labor is saved.

3, For roller heating system, The heatable roller can be equipped, and ita s hollow roller heated by hot oil circulation system, So it can save lots of cost.

4, For roller space adjusting system, The power drive or servo drive system is adoptedto control the rollera s gap, ita s easy to operate to adjust the rollera s gap,

5, For the roller gap detection, the roll gap is detected by high quality grating scale, display the gap distance in real time, so it can precisely control the each roller gap, and ensure the products precision.

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company, Wholesaler, Producer

Employee Count

50

Establishment

2009

Working Days

Monday To Friday

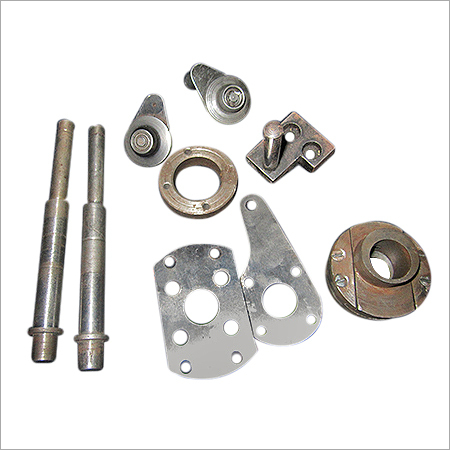

Related Products

More Product From This seller

Seller Details

Kunshan, Jiangsu

Ms Loral Kong

Address

No. 109, Yisheng Road, Suzhou City, Kunshan, Jiangsu, 215316, China

Industrial Machinery & Parts in Kunshan

Report incorrect details