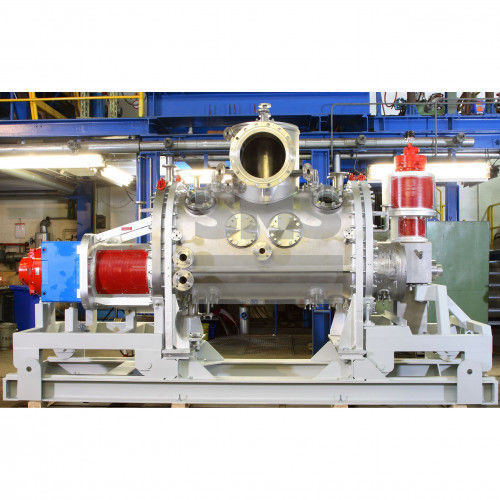

Single Shaft Segmented Disc Processor Reactotherm

Price Trend: 150000.00 - 3000000.00 EUR

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Material | Stainless Steel |

| Dimensions | Variable |

| Capacity | Customizable |

| Power | Variable |

| Heating/Cooling | Yes |

| Rotation Speed | Adjustable |

| Pressure Rating | Variable |

| Features | Intensive Mixing, Self-Cleaning, High Efficiency, Versatile Use, Continuous/Batch, Easy Cleaning, Reduced Fouling, Precise Control |

| Product Type | Single Shaft Segmented Disc Processor Reactotherm |

| FOB Port | Northsea harbour |

| Payment Terms | Letter of Credit (L/C), Telegraphic Transfer (T/T) |

| Supply Ability | On Order Per Day |

| Delivery Time | 7-15 Monate Months |

| Main Export Market(s) | Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia |

| Main Domestic Market | All India |

Product Overview

Key Features

The Reactotherm is a heavy duty processor with an intensive mixing and kneading effect and self-cleaning ability. It is used for thermal processing of a wide variety of pasty, viscous, and fouling products. It can be operated continuously or batch-wise.

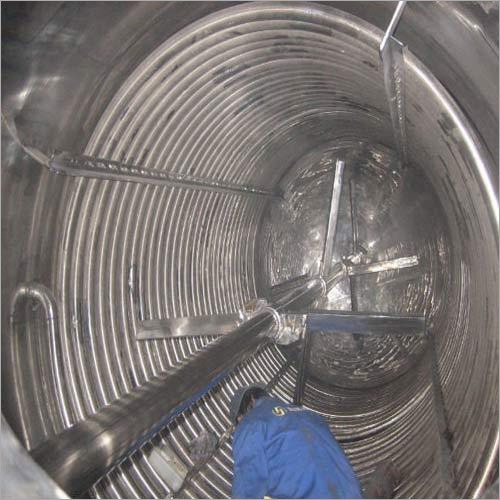

The Reactotherm consists of a cylindrical, horizontal shell and a rotor with segmented discs and mixing bars. Stationary mixing hooks are attached to the inside of the shell. The close clearance between the mixing hooks, the segmented discs and the rotor result in a high mixing and kneading effect and the self-cleaning properties of the rotor. The inside of the shell is cleaned by the mixing bars. Fouling of heat exchange surfaces and the formation of agglomerates are avoided. The shell, the rotor shaft and the discs can be heated or cooled. The product transport is accomplished by the slightly pitched mixing bars.

Company Details

We are number 1 in thin film evaporation technology and a global leader in drying and high viscosity technology. We develop and construct plants and equipment for such processes as the evaporation, drying and processing of highly viscous materials. Solutions that are exactly as you need them exceptionally precise, efficient and, when necessary, highly innovative. With our plants, systems and reconceptualised solutions we have been setting standards in thermal separation technology for many years and are your specialist for outstanding processing of mixtures which are difficult to handle. Over 200 highly qualified and experienced experts work at our main site in Butzbach and our branches in D'ren and Pratteln (Switzerland) to apply the SMS vision of excellence across all the sides of our business in their work for and with our customers.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

230

Establishment

1919

Working Days

Monday To Friday

Payment Mode

Online Payments (NEFT/RTGS/IMPS), Cheque/DD

Certification

AD 2000, AD 2000-Merkblatt HP 0, ASME Section VIII, Division 1, ASME U, ATEX 2014/34/EU, China Stamp, DIN EN 13445, DIN EN 13480, DIN EN ISO 14001, DIN EN ISO 9001

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Butzbach, Hessen

Sales Manager

Mr. Rainer Fabricius

Members since

7 Years

Address

Kaiserstrasse 13 - 15, Butzbach, Hessen, 35510, Germany

chemical reactors in Butzbach

Report incorrect details