Sigma Mixer - Extruder Screw Design For Viscous Material Processing | Double Arm Sigma Blade Action, Adjustable Flow, Versatile Die Head Discharge, Efficient Shearing And Tearing Mechanism

Price:

Get Latest Price

Brand Name :

Microtech Engineering

In Stock

Product Specifications

| FOB Port | yes |

| Payment Terms | Cash on Delivery (COD), Paypal, Others, Letter of Credit (L/C), Western Union, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA) |

| Supply Ability | 100 Per Year |

| Delivery Time | 3 Week |

| Sample Policy | Free samples available with shipping and taxes paid by the buyer |

| Packaging Details | PACKING, WOODEN BOX |

| Main Export Market(s) | Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa |

| Main Domestic Market | All India |

| Certifications | ISO 9001 : 2015 |

Product Overview

Key Features

Uniform Kneading, Mixing and Extruding Process

Application & Process :

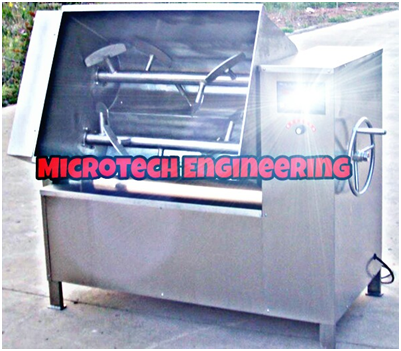

The Sigma Mixer with extruder is used for mixing, kneading and extruding of highly viscous mass, sticky and dough like products, Mixing of pastes, rubber, and heavy plastic masses, applications in Food, Rubber, Pharmaceutical, Chemical and agro industries, Dry powder to wet phase mixing. This mixer is most suitable for highly viscous material and dough like masses.The extruder mixer is designed to handle difficult to discharge products such as hot melts and butyl sealants, as well as other medium to high viscosity pastes. This type of mixer combines the action of the Double Arm Sigma Blade Mixer with an extrusion screw placed in the lower part of the mix trough. During mixing, the extrusion screw is run in reverse which imparts a third mixing action on the product, increasing mixing efficiency.

The sigma kneader is a double arm mixer with extruder, the two "Z" blade rotate towards each others at same or different speed inside a W- shaped product container and extruder screw is located between the two blade with separate gear motor drive. Each blade moves the material in opposite direction thereby providing excellent cross mixing of all raw materials. The blades pass the trough walls and each other at close clearances resulting in good mixing. The close clearance produces a shearing and tearing action that is beneficial to the size reduction of solids.The extrusion screw is located in the saddle section and runs in a cylindrical trough tangential to and below the 2 mixing blades. When the product has finished the mixing cycle, discharge/extrusion is performed simply by running the extrusion screw in a forward direction. By changing the extrusion die heads, the product can be discharged in round, square, "spaghetti", or any form desired. Speed variation of the extrusion screw allows adjustment of the product flow, depending on the viscosity.

Company Details

We are among the Reputed Manufacturer and Exporter of Globe Valve, Hydraulic Globe Valve, Back Pull Out Pump, Dosing Pump, Filter Press Pump, Forged Instrument Pipe Fittings, Magnetic Drive Pump, and many more. These products are manufactured with advanced technology and finest grade of raw material. Also, customization facility is also offered with the products so that customer exact demand can be duly met. Our entire product range is widely appreciated for its lasting performance, zero maintenance, corrosion & abrasion resistance, rugged construction and minimal power consumption. It is being packed in genuine and durable wooden boxes which aids in ensuring safe delivery. Further, client can avail the range at industry leading prices suiting to their pocket size

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company, Wholesaler, Retailer, Dealer, Fabricator

Employee Count

5

Establishment

2010

Working Days

Sunday To Sunday

GST NO

07AASFM3267H1ZV

Payment Mode

Cash in Advance (CID)

Certification

iso 9001:2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AASFM3267H1ZV

Delhi, Delhi

Partner

Mr Mehtab

Members since

13 Years

Address

L-89, Krishan Vihar, Near Bharat Shakti Public School, Delhi, Delhi, 110086, India

industrial ribbon blender in Delhi

Report incorrect details