Sea Water Desalination Plant - Stainless Steel Skid, 12-15 Kg/cm2 Pressure, 90-95% Total Dissolved Solids Removal | Multi-stage Filtration, Electronic Chemical Dosing, High Efficiency Reverse Osmosis

Price:

Get Latest Price

In Stock

Product Overview

Key Features

Sea Water Desalination Plant

Area of Applications.

Mineral Water Plants.

Schools, Colleges & Institutions.

Hospitals & Nursing Homes.

Pharmaceutical Industries.

Swimming Pools and Water Parks.

Residential & Housing Complexes.

Hotels & Resorts.

Food Processing Units.

Dairy Plants.

Poultry Farms.

Sea food Exporters.

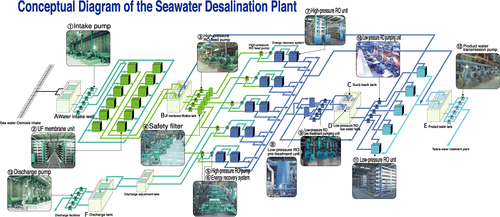

PROCESS OF RO PLANT

01. RAW WATER SUPPLY PUMP:

Centrifugal pump in C.I construction is required for feeding raw water from underground/overhead raw water storage tank to PSF to ACF and then on to MCF with flow rate of 12 M3 per Hour. The pump is fitted with suction/discharge pipe work, isolation valves and pressure monitor

02. PRESSURE SAND FILTER:

This is a FRP Pressure vessel with internal distribution, collection, frontal and interconnecting pipes and requisite valves of SS construction along with one lot of fine sand, silex and pebbles. The necessary instruments like inlet/outlet, pressure monitors and Multiport Valve for Backwash, rinse and filter provided with the system. All the suspended solids and dust particles from the raw water is removed here

03. ACTIVATED CARBON FILTER:

This is a FRP Pressure Vessel with internal distribution, collection, frontal and interconnecting pipes and requisite valves of SS construction along with one lot of fine wash high iodine content carbon flakes. The necessary instruments like inlet/outlet, pressure monitors and Multiport Valve for backwash, rinse and filter provided with the system. All the physical impurities such as odour and colour of raw water is removed here

04. MICRON CARTRIDGE FILTER

The Module consists of Multiple Polypropylene Cartridges with size of 10/5 Micron that prevents micron size particles up to 5 micron. Necessary instrument like inlet/outlet pressure monitor and a Flow indicator is provided with requisite isolation valves.

05. CHEMICAL DOSING PUMP:

This is electronic chemical injection system to remove all scale formation minerals from process raw water to reverse osmosis membranes and is precautionary measure to shield the membranes from blockage of pores.

06. HIGH PRESSURE PUMP

One No. of Vertical Mounted Multi stage centrifugal High Pressure Pump with SS construction. The High Pressure Pump supply raw water with pressure of 12 to 15 kg/cm2 to RO Membranes, where permeate is separated. The necessary instruments like High and Low pressure switch, pressure monitor and requisite isolation valves provided.

07. DESALINIZATION BY REVERSE OSMOSIS SYSTEM

R.O. System removes 90-95% of Total Dissolved Solids by the principle of Reverse Osmosis Process. This system consist of a Stainless Steel Skid for mounting of high pressure tubes in FRP with resistance of 150 psi for pressure housing spiral wound TFC Membrane elements With necessary control valves at feed, product and reject pipe are provided with required instruments like Low and High pressure switches are provided for safe operation of High Pressure Pump under specified operating conditions. Pressure monitor is provided for pressure indication and control of complete R.O.System. An online flow indicator at product and brine pipe work is provided for controlling desired flow rate and recovery. For monitoring product water quality an online conductivity indicator is provided.

Company Details

Focusing on a customer-centric approach, FREEION ENGINEERING has a pan-India presence and caters to a huge consumer base throughout the country. Get Water Treatment Plants from FREEION ENGINEERING at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Establishment

2001

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Gandhinagar, Gujarat

C.E.O.

Mr. Keyur Thakkar

Address

3, SF, Hariram Enclave, B/h Raison Petrol Pump, Kudasan, Gandhinagar, Gujarat, 382424, India

sea water desalination plant in Gandhinagar

Report incorrect details