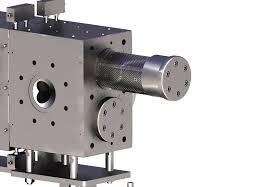

Screen Changer - Rotary Shaft Operated, Rugged And Corrosion Resistant | High Performance With Low Maintenance And Prolonged Service Life

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Color | Silver |

| Dimensions | Variable |

| Weight | Variable |

| Stations | 1-6 |

| Usage | Polymer extrusion screen changing; perforated metal sheet handling |

| Compliance | Industry Standard |

| Features | High performance, Rugged construction, Low maintenance, Easy operation, Long lifespan, Power saving, Production boost |

Product Overview

Key Features

Owing to our rich domain expertise in this very domain, we are competent to manufacture and supply Screen Changer. Operated by a rotary shaft, our product is ideally used in polymer extrusion of different perforated metal sheets. Offered machine undergoes stringent quality calibration testing with our in-house infrastructure, thus ensuring its flawlessness in terms of quality and performance. Some of the eminent features of our Screen Changer are mentioned in the below enlisted bullets:

- Rugged construction

- Corrosion & abrasion resistance

- High performance

- Prolonged service life

- Low maintenance

Screen Changer

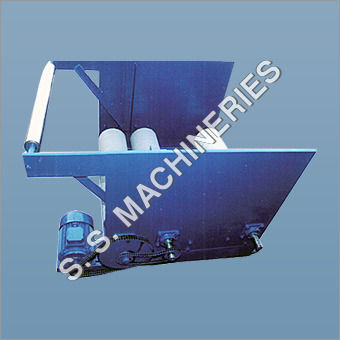

Advantage (Single Station to Six Satiation Cutter):

- Absolutely eliminated ideal time

- Maximum utilization of tape plant

- Easy to operate

- In Six Station Cutter, Blades will be changed after 6 days

Payback:

- Power Saving : In each stoppage it takes minimum of 20 minutes to stop + 60 minutes to change blade + 20 minutes to start = The total time is 100 minutes.

- In hole of this time total system is ON means power loss is 60 minutes of working load = 150 Units (Power Saving Per Month =150 Units X 30 = 4500 Units)

- Production Enhancement : If we don't stop the plant twice in day we will get minimum one-hour production more. One hour production = 150 ~200 Kg.

- Hence, the payback period is only 2-3 months.

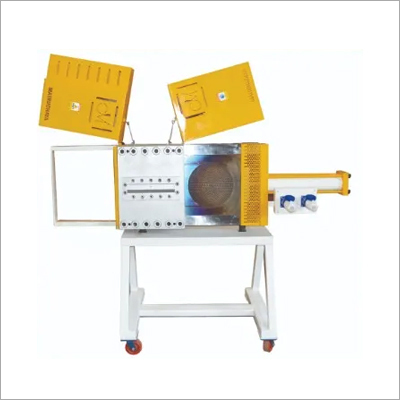

Six Station Cutter Consisting:

- Powder coated cutter assembly

- Cutter frame with cover & one roller

- One set of shaft

- Spacer duly assembled with super max blade

- Cutter Stand

Optional : One set of shaft and spacers w/o blades and assembly

Company Details

Focusing on a customer-centric approach, S. S. MACHINERIES has a pan-India presence and caters to a huge consumer base throughout the country. Get PP & HDPE Sacks from S. S. MACHINERIES at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Distributor, Supplier

Employee Count

20

Establishment

2001

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Ahmedabad, Gujarat

Partner

Mr. Sanjay Verma

Address

45, Puspak Industrial Estate, Nika Tube Compound, Phase-I, GIDC, Vatva, Ahmedabad, Gujarat, 382445, India

screen changer in Ahmedabad

Report incorrect details