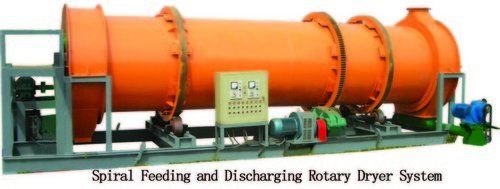

Saw Dust, Palm, Biomass, Stone Rotary Drum Dryer Machine

Price:

Get Latest Price

In Stock

Product Specifications

| FOB Port | any port |

| Payment Terms | Delivery Point (DP), Cash on Delivery (COD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Cash Against Delivery (CAD), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA) |

| Supply Ability | 100 Per Year |

| Delivery Time | 10-30 Days |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Bare packing and wooden box |

| Main Export Market(s) | Australia, South America, Middle East, Africa, Western Europe, Asia, Central America, Eastern Europe, North America |

| Main Domestic Market | All India |

| Certifications | CE ISO SGS |

Product Overview

Key Features

Main features

1. It can use chemical gypsum (Free gypsum dehydration, phosphogypsum etc) to fry I -semi-water gypsum directly.

2. From craft process, guarantee the requests of frying temperature and time which should make precise control in roasting the gypsum.

3. The discharging of work machine is designed rationally, when operation, there is no dust pollution.

4. When interval feeding and discharging, it can be banked fire and shut down furnace. The stove fire can be put into normal production after 3 minutes by again opening furnace.

5. Matched gas stove or fluidized bed furnace is used for supplying heat, the waste heat of tail gas can be used recycling. (Boil water, heat the air.

.

Working Principle

Rotating cylinder dryer is a new type continuous dryer which designed on foundation of absorbing foreign technology. The machine is equipped 3 sets inner barrel. Raw material fed from screw import, under the function of rake and hot air flow, raw material will get enough heat and mass transfer after second deflection. Dried product will be collected by cyclone separator of bag filter, damp air will be exhausted by fan.

Main technical parameters

Rotary drum dryer Instruction:

Rotary drier is widely used for drying materials in the industries of cemet, mine, contruction, chemical, food, compoud fertilizer, etc. Feeding and discharging unit is installed with thermocouple to control drier temperature. The temperature change of drier's feeding end can be indicated by the thermometer to control the inner drier temperature ( generally 250-350A C)

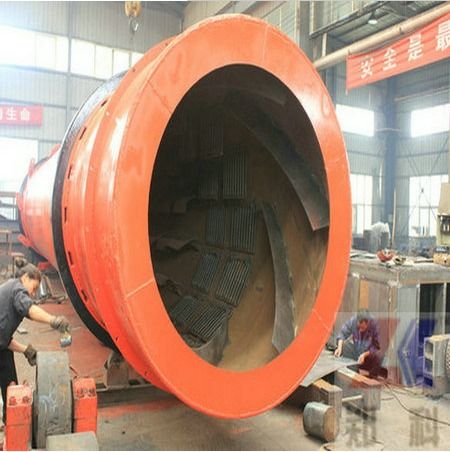

Rotary drum dryer Structure:

Rotary drier machine is mainly composed of shell, back and forth supporting wheel, feeding and discharging unit and gear cap. The accessories which are not in the the scope of this machine include firebox, feeding and discharging equipment, dust catcher, etc.

Rotary drum dryer working principle:

Rotary drier adopts direct flow type of heating with heat soure from firing unit. The material to be dried is pushed back immindiately by spiral board when enters the shell from feeding tank and feeding chute. Because the drier is installed in slope, material flows to the back end under gravity and rotation force, meanwhile, it is lifted by board repeatedly and thrown down accordingly, which make the material form even curtain, and exchange heat sufficiently with inner the heat flow. In the end, water in the material is dried by repeatedly scattering.

1. High Capacity Rotary Drum Dryer advantages:

reasonable structure, polished manufacture, high capacity, low energy consumption, smooth rotation, easy operation, convenient transportation and so on.

2. Rotary Drum Dryer main parts:

cylinder, lifters, driving device, supporting device and sealing ring, feeding device, discharging device, gear, gearbox, electric mo

Company Details

Focusing on a customer-centric approach, Henan Dianyan New Energy Technology Co., Ltd has a pan-India presence and caters to a huge consumer base throughout the country. Buy Industrial Dryers in bulk from Henan Dianyan New Energy Technology Co., Ltd at Trade India quality-assured products.

Business Type

Exporter, Manufacturer

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Zhengzhou, Henan

Mr. Shawn Gao

Address

Room 325,Building 1,No. 55 Lianhua Street , High-Tech Zone, Zhengzhou, Henan, 450000, China

rotary dryer in Zhengzhou

Report incorrect details