Saideli Gkf Series High-quality Horizontal Two-phase Separator - Automatic Grade: Automatic

Price: 4857398.28 INR / Sets Sets Sets

Get Latest Price

Minimum Order Quantity :

1 Sets Sets Sets

In Stock

Product Specifications

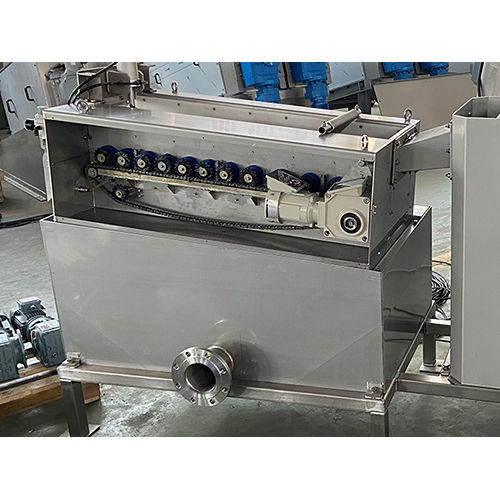

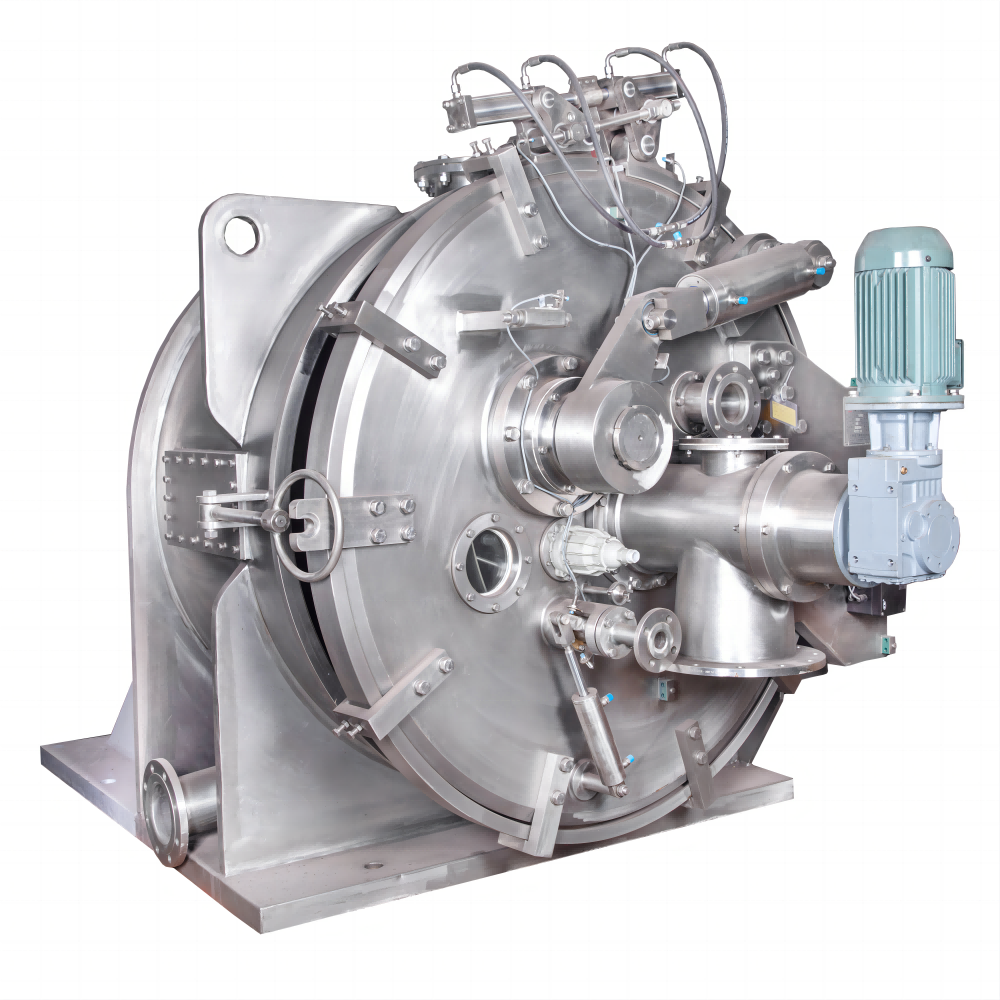

| Type | Peeler Centrifuge |

| Material | Stainless steel |

| Capacity | 100 Ltr/hr |

| Computerized | Yes |

| Automatic Grade | Automatic |

| Voltage | 220 Volt (v) |

| Size | 3191*2100*2140mm |

| Width | 2100 Millimeter (mm) |

| Weight | 230-280 Kilograms (kg) |

| Dimension (L*W*H) | 3191*2100*2140mm Millimeter (mm) |

| Warranty | 1 year |

| FOB Port | Shanghai |

| Payment Terms | Telegraphic Transfer (T/T), Letter of Credit (L/C) |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa |

| Main Domestic Market | All India |

| Certifications | ISO CE |

Product Overview

Key Features

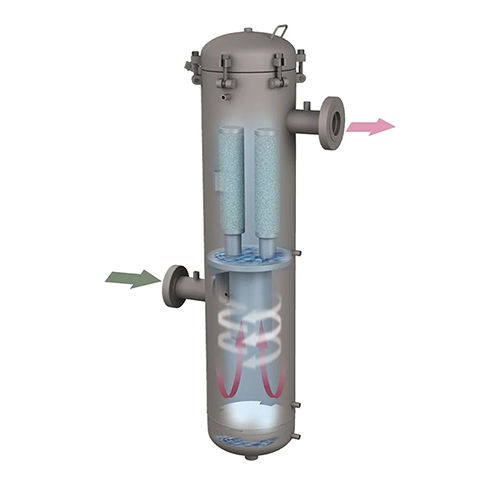

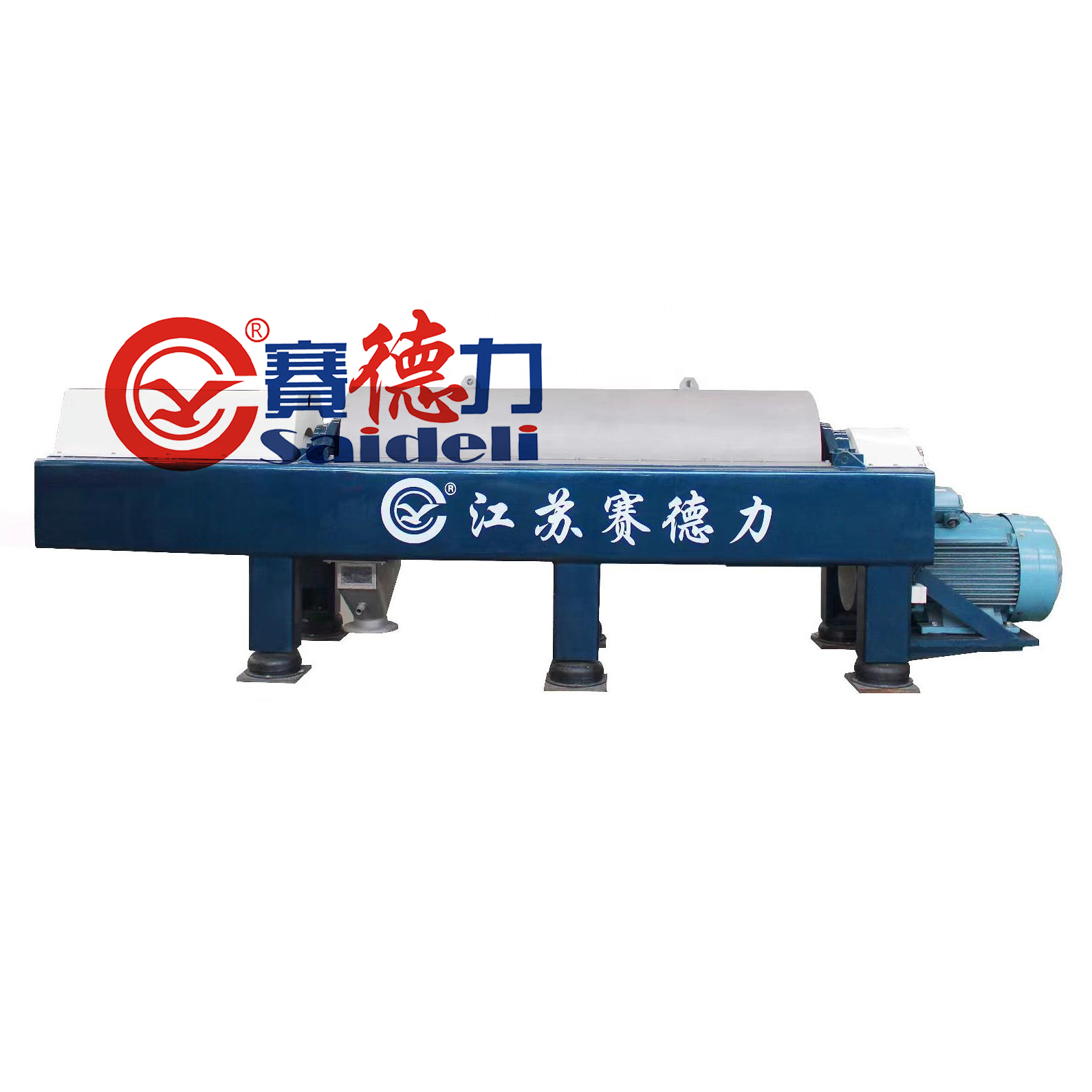

GKF Series Automatic Horizontal Scraper Centrifuge

Main Features

Company Details

Jiangsu Saideli Pharmaceutical Machinery Manufacturing Co., Ltd. is a high-tech scientific research and production enterprise. Established in 1953, our head office is located in Jingjiang City of Jiangsu Province in the economically developed Yangtze River Delta region of China. Now, Saideli enjoys a unique economic environment and geographical position, as well as a beautiful environment: Situated at the north end of the Jiangyin Changjiang Highway Bridge, Saideli is adjacent to Beijing-Shanghai Expressway, Nanjing-Tongji Expressway, Tongsan Expressway and Yanjiang Expressway, and can reach to Shanghai and Nanjing city easily. As a professional manufacturer of centrifugal and drying equipment, Saideli now is the Member Unit of China Separation Machinery Standardization Technical Committee, Drafting Unit of China Pharmaceutical Centrifugal Separation Machinery Requirements (JB/T20139-2011), Vice Chairman Unit of China Separation Machinery Industry Association, Member Unit of National Pharmaceutical Equipment Standardization Technical Committee, Director Unit of China General Machinery Industry Association, national high-tech enterprise, Vice President Unit of China Chemical Pharmaceutical Industry Association, and Director Unit of China Intelligent Pharmaceutical Equipment Professional Committee; Moreover, we have the manufacturing licenses of China for pressure vessel special equipment. Covering a total area of 500, 000m2, Saideli Company consists of eleven major modules such as Jiangsu Saideli Pharmaceutical Machinery Manufacturing Co., Ltd., Jiangsu Zhongyi Energy Saving Technology Co., Ltd., Jiangsu Zhongyi Environmental Protection Technology Co., Ltd., Jingjiang Saideli Fine Filtration Equipment Co., Ltd., Jingjiang Saideli Eco-Agriculture Co., Ltd and Jiangsu Fengxing Textile Co., Ltd, etc. There are flourishing plants and trees, and modern factory facilities in Saideli Company now; That is the representative of the new scene of China's booming manufacturing industry.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

2000

Establishment

1953

Working Days

Monday To Sunday

Payment Mode

Letter of Credit (L/C)

Certification

ISO CE

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Taizhou, Jiangsu

Sales Person

Mr. Benjamin Dai Wilson

Address

No. 31, Zhongzhou Road, Jingjiang City, Taizhou, Jiangsu, 214500, China

Report incorrect details