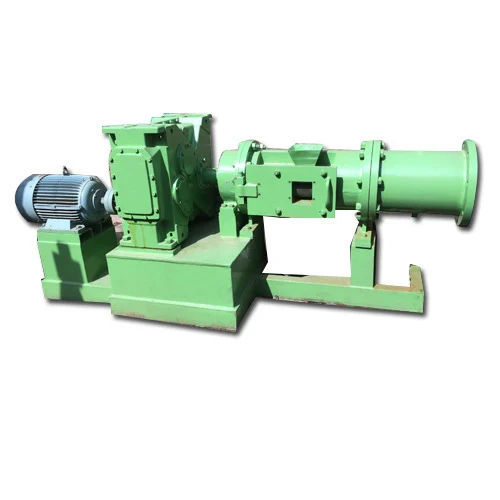

Hot Feed Extruder - En-41 Nitrated Steel Screw, 50/2" Diameter, 5/6 L/d Ratio | Heavy Duty Design, Hygienic Operation

Price:

Get Latest Price

In Stock

Product Specifications

| Screw Material | EN-41B steel |

| Barrel Material | Steel |

| Liner Material | 41B steel |

| Bearing Type | Roller thrust |

| Drive Motor | 2-60 HP |

| Output | 10-1400 kg/hr |

| Color | Green |

| Features | High output, Low energy, Durable design, Easy operation, Smooth function, Long lifespan, Versatile use, Precise control |

Product Overview

Key Features

We are a noteworthy organization in the domain, engaged in providing high quality range of Hot Feed Extrude that is mainly used in food, pharmaceutical and many other industries to create the objects of a fixed cross-sectional sizes. Offered machine is manufactured at our highly advanced production unit using pristine quality components and sophisticated technology following industry defined guidelines. Moreover, provided Hot Feed Extrude is extensively admired by our prestigious customer for its smooth functioning and long service life.

Specifications:

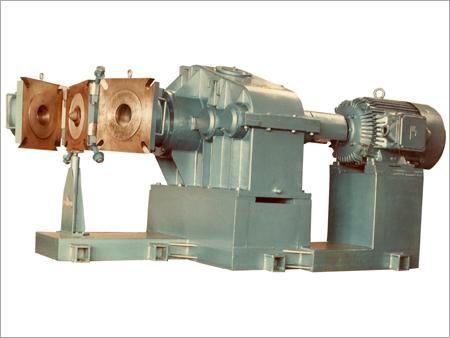

SCREW: EN-41. B Nitrated steel scroll having hardness approx. 58-59 RC. Upgraded lead design for maximum, constant output with minimum energy consumption.

BARREL: Seamless barrel housing steel fabricated double jacketed for water cooling or steam heating arrangement as per specific requirements with robust design for heavy extruder loads for trouble free operations.

LINER: 41.B Nitrated steel liner having hardness approx. 58-59 RC.

BEARING: Heavy duty tapper roller thrust bearing provided in both end of barrels to bear up heavy extruder load.

FEED HOPPER: Specially designed under cut at feeder hopper area to ensure regulated material inflow and constant flow at the die face end. (Feed roller on hot feed extruders offered only on request above 60 mm).

DIE HEAD HOLDER: Removable threaded die head holder with hinged/fixed bolts. Clutch type, hinged type or hydraulic/preumatically openable die holders are also offered on request as option.

STAND & BASE: Heavy duty steel fabricated monobloc constructed.

COUPLING: Star type heavy duty coupling or directly coupled to the gearbox shaft with heavy duty 'V' belt transmission from motor to gearbox. As per standard design or requirement.

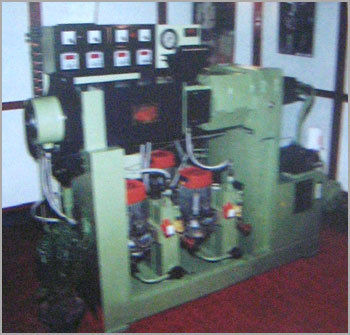

REDUCTION GEAR: SHEL make special hollowed shaft, thrust bearing fitted on the output shaft, profile grounded/soft series gear reducer units as standard or with separate bearing housing with extra heavy duty tappered/thrust roller bearing coupled directly to gearbox output shaft as per customers requirement. Other make gear reduces are also used.

| SCREW DIA | L/D RATIO | RPM | DRIVE MOTOR | OUTPUT (kg /hr) |

|---|---|---|---|---|

| 40 / 1.5" | 5 / 6 | 58 - 70 | 2HP | 10 - 15 |

| 50 / 2" | 5 / 6 | 58 - 65 | 3HP | 25 - 35 |

| 75 / 3" | 5 / 6 | 52 - 62 | 7.5 HP | 40 - 55 |

| 100 / 4" | 5 / 6 | 42 - 48 | 10 HP/15 HP | 65 - 130 |

| 115 / 4.5" | 5 / 6 | 58 - 70 | 15 HP/20 HP | 160 - 320 |

| 125 / 5" | 5 / 6 | 36 - 44 | 30 HP/40 HP | 18 - 460 |

| 150 / 6" | 5 / 6 | 32 - 38 | 50 HP/60 HP | 280 - 750 |

| 200/ 8" | 5 / 6 | 28 - 36 | 60 HP175 HP | 400 - 1400 |

Company Details

Focusing on a customer-centric approach, V. I. P Machinery has a pan-India presence and caters to a huge consumer base throughout the country. Buy Rubber Extrusions in bulk from V. I. P Machinery at Trade India quality-assured products.

Business Type

Manufacturer, Supplier, Trading Company

Establishment

1978

Working Days

Monday To Sunday

GST NO

07AIOPH3257Q1ZL

Payment Mode

Others

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AIOPH3257Q1ZL

Delhi, Delhi

Proprietor

Mr. Haider Malik

Address

Plot NO- F-95, New Seelampur, Near. Police Station, Delhi, Delhi, 110036, India

hot feed rubber extruder in Delhi

Report incorrect details