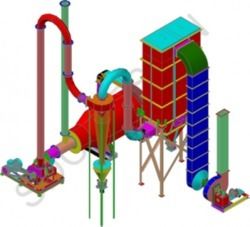

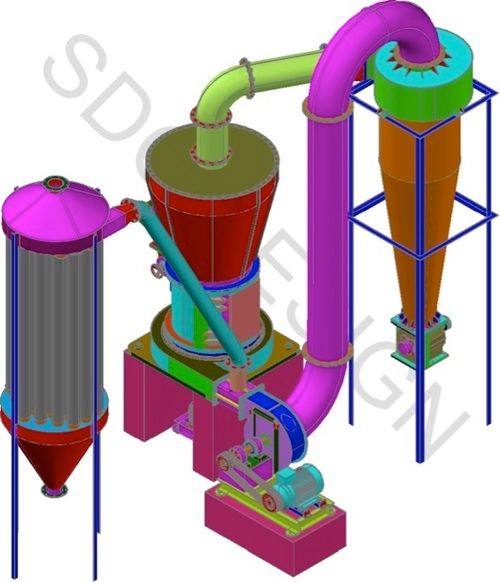

Roller Mill - Medium To Fine Grinding System | Integral Separator, Automatic Dust-free Operation, Efficient Air Circulation, Attrition And Compression Grinding Principle

Price:

Get Latest Price

In Stock

Product Specifications

| Product Type | Roller Mill |

| Dominant Color | Red |

| Rollers | 3/5 |

| Grinding Principle | Attrition |

| Power | Variable |

| Capacity | Variable |

| Material | Steel |

| Usage | Medium to fine grinding and classification of minerals/ores |

| Compliance | Local |

| Features | Fine grinding, Dust free, Automatic, Efficient, Mineral, Ore |

Product Overview

Key Features

The grinding operation in Singhasini 3 / 5 Roller Mill is performed on the principle of attrition and compression, which results due to the centrifugal force generated from the suspended Rollers running inside a stationary Bull Ring.

The MINERAL to be pulverized enters the grinding chamber through an automatic feeder and falls onto the mill floor whereby it is scooped up by steel ploughs into the nip space between the rollers and the bull ring where grinding takes place.

A constant quantity of air is circulated through the mill and system. The air from centrifugal blower enters the mill through a series of tangential ports round the base of grinding chamber and sweeps the fine and medium fine MINERAL to the classifier above the grinding chamber leaving no ground material in the chamber and allowing the rollers to work efficiently crushing the coarse MINERAL.

The Classifier separates the Pulverized MINERAL and coarser particles return back to the grinding chamber for further size reduction. Fine MINERAL is carried by air to the cyclone air separator where air and ground material are separated and collected. The clean air is returned to the blower for close circuit grinding operation.

Clients can avail this Roller Mill at industry leading prices from us.

Company Details

Focusing on a customer-centric approach, Singhasini Engineers & Consultants has a pan-India presence and caters to a huge consumer base throughout the country. Buy Grinding & Milling Machinery in bulk from Singhasini Engineers & Consultants at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Establishment

2009

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Kanpur, Uttar Pradesh

Ceo

Mr. Sanjay Srivastava

Address

303,Parv Appt. 3/90, Vishupuri, Kanpur, Uttar Pradesh, 208002, India

roller milling machine in Kanpur

Report incorrect details