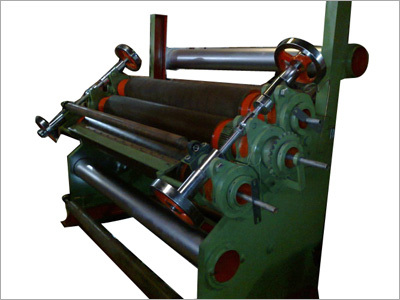

Rnn-320c Fingerless Type Single Facer - 1400mm-2200mm Effective Width, 150 M/min Design Speed | High-temperature Lubricate Grease, Vacuum Suction Cardboard Transmission, Durable 48 Crmo Alloy Steel Construction

Price: 2500000.00 INR / Set

(2500000.00 INR + 0% GST)

Get Latest Price

1 Pack Contains :

1

Minimum Pack Size :

1

In Stock

Product Specifications

| Color | Any |

| Product Type | Single facer Corrugation Machine |

| General Use | Cardboard transmit adopt vacuum suction method with wind control system. Keep flute profiles stable of the lower aEUR" roller in the condition of running up. Bearing of the corrugated and pressure roller to adopt high temperature lubricate grease. |

| Material | Paper |

| Capacity | 20-40 T Ton/day |

| Weight (kg) | 7000 Kilograms (kg) |

| Type | Corrugated Box Making Machine |

| Function | Cardboard transmit adopt vacuum suction method with wind control system. Keep flute profiles stable of the lower aEUR" roller in the condition of running up. Bearing of the corrugated and pressure roller to adopt high temperature lubricate grease. |

| Computerized | No |

| Automatic | No |

| Drive Type | Electric |

| Power | 11 Horsepower (HP) |

| Voltage | 380 V Volt (v) |

| Feature | Vacuum Suction |

| Warranty | 1 Year |

| FOB Port | Mumbai |

| Supply Ability | 5 Per Month |

| Delivery Time | 1 Months |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Standard export packing |

| Main Domestic Market | All India |

| Certifications | ISO 9001 |

| Price Type | fixed |

| Returnable | No |

| Brand Name | Nagpal Natraja |

| Stock Quantity | 15 |

| Packsize | 1 |

| Moq | 1 |

| Unit Type | Set/Sets |

| Color | Any |

| Mop | 1 |

| Currency | INR |

| Product Unit | 5 Set/Sets |

| Price | 2500000.00 INR (Approx.) |

| Minimum Order Quantity | 1 |

| Minimum Ordered Packs | 1 |

| GSTIN | 0% |

Product Overview

Key Features

Specification

320C Design Speed: 150 m/min 360C Design Speed: 180 m/min

Effective width: 1400 mm- 2200 mm

Corrugated roller : 320 mm / 360 mm

Drive reducer box with oil immersed type lubricating to reduce noise keeps running stable. Adopt gimbal transmission. Separate power. (optional)

corrugated roller, the pressure roller and glue roller by pneumatic adjustment.

Cardboard transmit adopt vacuum suction method with wind control system. Keep flute profiles stable of the lower Aca a roller in the condition of running up.

Bearing of the corrugated and pressure roller to adopt high temperature lubricate grease.

Glue parts auto supply glue circularly.

The upper Aca a lower corrugating roller is made of 48 CrMo high-quality alloy steel after heat treatment. The hardness HV1200 the surface be grinded.

The glue part surface is treated by special mesh snicked and chrome plated.

Motorized or manual glue width dividing to match the proper width.

Glue part can be running independently or non independently while stopped.

Company Details

Equipment manufacturing companies that experience consistent growth have one thing in common- they not only adopt best industry practices in production but also take smarter and quicker decisions in the face of complexities. They always work within frameworks where their activities are not disrupted due to economic uncertainty, supply chain instability and other factors. Among such successful Indian manufacturing companies is Natraj Corrugating Machinery Company from Faridabad, Haryana, India. Specializing in the production of Nagpal 5 Ply Automatic Corrugated Board Plant, Automatic Flexo Printer Slotter Die Cutting Machine, Automatic Folder Gluer And Stitching, Automatic Flute Laminator, Automatic Kappa Board Making Plant, etc., the company serves clients from all over the world, including the markets of Mexico, China, South Africa, Turkey and Algeria, helping them get specific and special machining solutions at the lowest possible prices in the global market.

Natraj Corrugating Machinery Company creates and quality checks all of its products at its headquarters. Each manufacturing and quality testing stage is therefore firsthand followed by its experienced team of engineers, designers and other professionals who know how to create best-in-class solutions utilizing new and robust technologies, i.e., produce high-tech systems that significantly reduce expenses of time and resources at the clients end. This state-of-the-art facility has provisions for producing 3ply, 5ply, 7 ply and many other types of corrugated boards in bulk. In view of the latest manufacturing technology and trends, various high-speed fully automatic printing, slotting, paper corrugating board making and other machines have been installed at the setup for creating great manufacturing value at each production cycle.

The company engineers to perfection almost 10 units of Nagpal 5 Ply Automatic Corrugated Board Plant, Automatic Flexo Printer Slotter Die Cutting Machine, Automatic Folder Gluer And Stitching, Automatic Flute Laminator, Automatic Kappa Board Making Plant, etc., which are then supplied all over the country or exported to other regions as per demand. Contact the company to find out how you too can make great savings when buying machines for your corrugation products factory!

Leadership

Many leaders when confronted with challenges fail to take quick decisions for the mutual benefit of both company and clients. However, Natraj Corrugating Machinery Company has ruled in a competitive domain where many unscrupulous, price-cutting competitors rear their heads every other day. Such companies have failed to disrupt its niche, all because Natraj is managed well by a leader like Mr. Rishi Nagpal. His sound background and relationship-oriented style of working have immensely benefited the company in all these years. A proud recipient of various industry awards, he expertly directs the company and cultivates a culture where employees are structured to support clients at every step. He also keeps them motivated so that they proactively serve clients with absolute professionalism and positivity.

Markets & Industries

Natraj Corrugating Machinery Company offers 5 Ply Automatic Corrugated Board Plant, Automatic Flexo Printer Slotter Die Cutting Machine, Automatic Folder Gluer And Stitching, Automatic Flute Laminator, Automatic Kappa Board Making Plant, etc., which can be used to precisely cut and create paper grey boards, paper solid boards, paper kapa boards, etc., with high speed and energy efficiency. A few of its products are also engineered for facilitating low-cost, efficient printing on various materials, ranging from LDPE, HDPE, Polyester Films, PVC Films, Paper, Aluminum Foils, Woven & Non-Woven Fabrics, etc, making them suitable for use in the following industries:

- a) - Food & Beverage Industry

- b) - Dairy Industry

- c) - Oil Industry

- d) - Bakery Product Industry

- e) - Paper Industry

- f) - Bag Making Industry, etc.

Technology & Machines Used

Modern technology providers need to have access to the right technology themselves for accelerating their market success and growth. Natraj Corrugating Machinery Company follows a strategic road map for practising advanced manufacturing works at its purpose-built factory in Faridabad, Haryana. As a part of its high-productivity strategies, it also invests in the following machines for streamlining production runs:

- 1. Printing & Slotting (Die-Cutting) Machines

- 2. Fully Automatic Paper Corrugating Board Making Machines

- 3. Printing, Slotting & Die-Cutting Machines (Single-Color, 2-Color, 3-Color And 4-Color)

- 4. Semi-Automatic (Chain Type) Rotary Slotting Machines

- 5. Common Type Rotary Slotting Machines

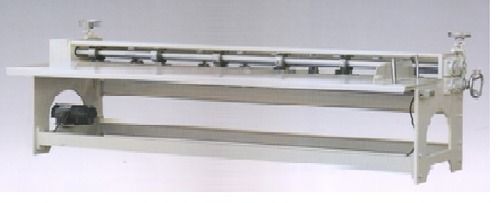

- 6. Thin Blade Paper Separating & Thin Edge Slitters

- 7. Fully Automatic (Air Suction Type) Round Pressing Round Die-Cutting Machines

- 8. Fully Automatic (Common Type) Round Pressing Round Die-Cutting Machines

- 9. Temperature-Controlled Corrugating Machines

- 10. Cylindrical Rotary Slotting MachinesÂ

- 11. Semi-Automatic Carton Bonding Machines

- 12. Quadruple Grooving & Corner Cutting Machines

- 13. Automatic Flatbed Die Cutting & Creasing MachinesÂ

- 14. Automatic Flute Laminator

- 15. Paper Separating Machines

- 16. Gluing Machines

- 17. Fully Automatic Carton Folder Gluer, etc.

Mission

To give weightage to product safety, quality and reliability, move beyond successful milestones of the past, and achieve newer ones as a market innovator of 5 Ply Automatic Corrugated Board Plant, Automatic Flexo Printer Slotter Die Cutting Machine, Automatic Folder Gluer And Stitching, Automatic Flute Laminator, Automatic Kappa Board Making Plant, etc., is the mission of the company.

Fact Sheet of Natraj Corrugating Machinery Company

| Nature of Business | Manufacturer, Supplier, Trader, Service Provider, Importer, Exporter |

| Year of Establishment | 1970 |

| Company Promoter | Mr. Rishi Nagpal |

| No. of Employees | 15 |

| Minimum Order Quantity | 1 Piece |

| Monthly Production Capacity | 10 Units |

| Annual Turnover | Rs. 5-10 Crores |

| Top Export Countries | China, Turkey, Mexico, Algeria and South Africa |

| Export Percentage | 40% |

| Import Percentage | 80% |

| Infrastructure Location Type | Semi-urban |

| Building Infrastructure | Permanent |

| Size of Premises | 500 square feet |

| Provide After Sales Support |

|

| IE Code | |

| Bankers | Axis Bank & HDFC Bank |

| GST No. | 06ACJPN8265D1ZG |

| Payment Modes | Cash, Cheque & DD |

| Shipment Modes | By Air, Cargo, Road & Sea |

Business Type

Exporter, Importer, Manufacturer, Service Provider, Supplier, Trading Company, Producer

Employee Count

15

Establishment

2004

Working Days

Monday To Sunday

GST NO

06ACJPN8265D1ZG

Payment Mode

Online Payments (NEFT/RTGS/IMPS)

Certification

ISO9001-2008

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 06ACJPN8265D1ZG

Faridabad, Haryana

Proprietor

Mr Rishi

Address

Plot No. 21-23, Mithrol Dist., Palwal, Faridabad, Haryana, 121105, India

single facer machine in Faridabad

Report incorrect details