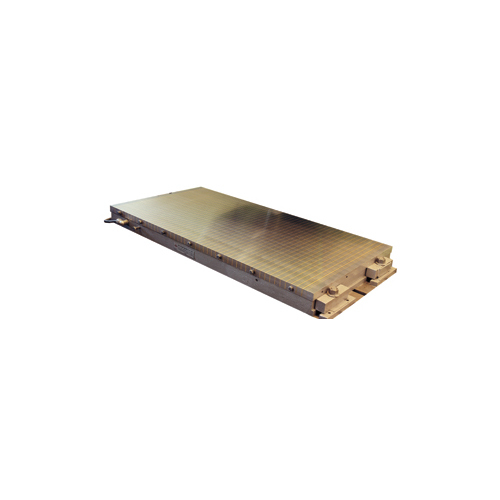

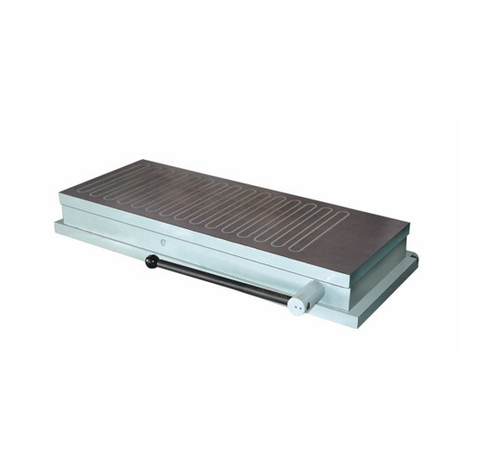

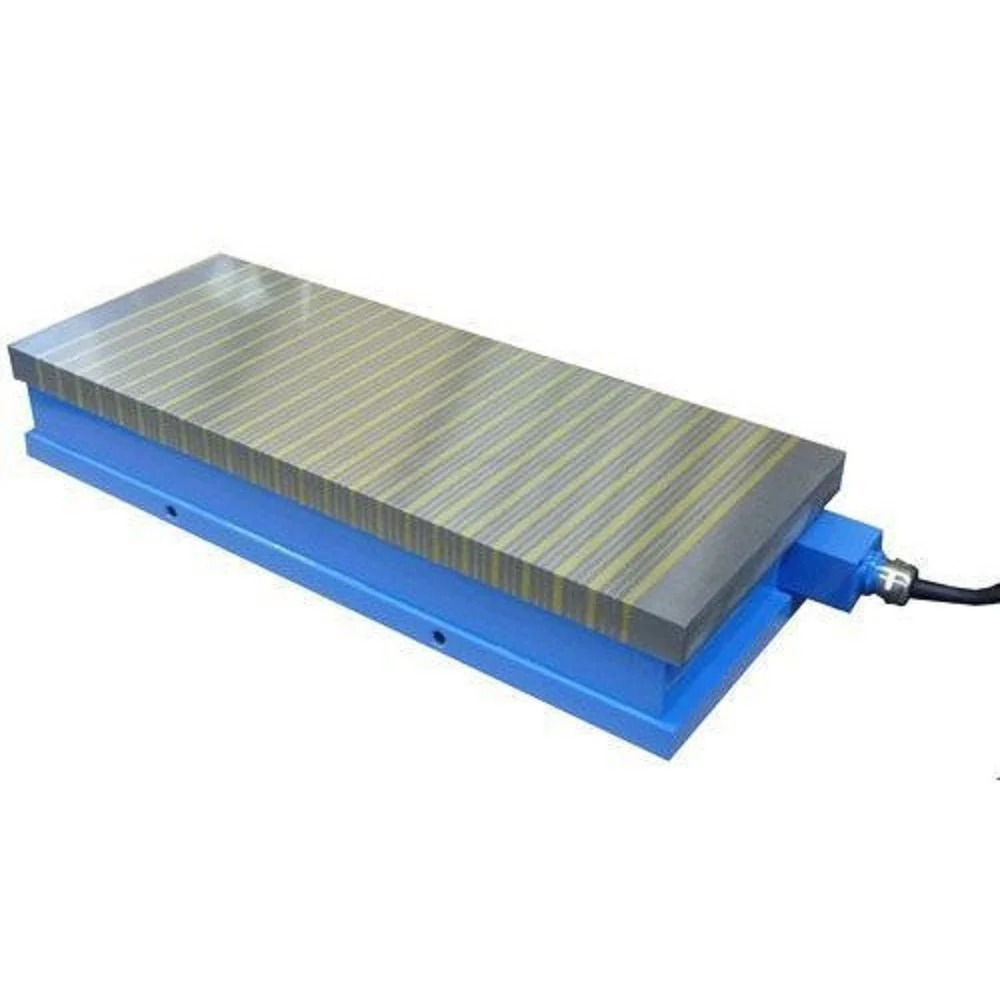

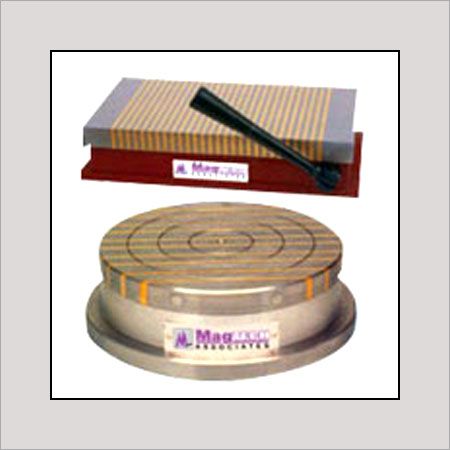

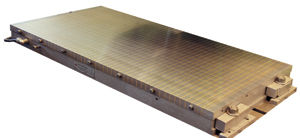

Rectangular Electro Magnetic Chucks

Price:

Get Latest Price

In Stock

Product Specifications

| Color | Red |

| Material | Cast iron |

| Dimensions | Variable |

| Power | DC |

| Holding strength | Variable |

| Usage | Holding larger components of mild steel and cast iron with low carbon content, free from oil and grease |

| Standards | Industry standard |

| Features | High efficiency, Easy operation, Low power, Quick residue removal, Automation ready |

Product Overview

Key Features

From our extensive range of magnetic chucks, we offer our precious clients a durable range of Rectangular Electro Magnetic Chucks. These magnetic chucks are used for holding bigger components. Maximum efficiency is obtained while the work pieces are made up of mild steel and cast iron and with the materials that have low carbon content and are free from oil and grease. Before delivering them from our end, the offered Rectangular Electro Magnetic Chucks undergo strict quality tests for confirming their flawless nature. Further, the provided magnetic chucks are made available in various specifications and can be purchased at pocket-friendly prices.

Features:

-

Highly efficient since workpieces can be loaded/unloaded only by switching operation.

-

Automation in machining process is realizable after interlocking the chuck with the machine tool.

-

Removes residues quickly

-

Requires low power consumption

-

Suitable for different workpieces

-

Attraction is electrically controllable

-

Easy to make larger type of chuck

Ajwa Rectangular Electro Magnetic Chucks are normally used for holding bigger components and maximum efficiency is obtained while the work pieces are of mild steel and cast iron and with materials having low carbon and free from oil and grease. The holding strength reduces as you use alloy steels and hardened material having more carbon percentage as the work pieces do not allow the magnetic fluxes to pass through the material easily.

Ajwa Rectangular Electro Magnetic Chucks are operated with D.C. Current using a rectifier of single phase A.C. Mains. The chucks are generally supplied without rectifier. The 'Ajwa' chucks are designed to operate instantly when the switch in 'ON' position. Te chucks are easy to operate by using 'On and Off switch'. The chucks lose their magnetic strength when they are switched off. However, for effective and immediate demagnetizing, a reversed low voltage D.C. Current should be applied using a reversing switch.

Company Details

Focusing on a customer-centric approach, AJWA MAGNETIC EQUIPMENTS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Magnets & Magnetic Devices in bulk from AJWA MAGNETIC EQUIPMENTS at Trade India quality-assured products.

Business Type

Manufacturer, Supplier, Trading Company

Establishment

1979

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Harihar, Karnataka

Accepts only Domestic inquiries

Proprietor

Mr. Ali Ahmed

Address

No.B1, Industrial Estate, Yantrapur, Harihar, Karnataka, 577602, India

magnetic chuck in Harihar

Report incorrect details