Reagents Used For Copper Flotation Efficiency: High Efficicy

Price Trend: 800.00 - 3500.00 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Material | carbon steel |

| Efficiency | high efficicy |

| Weight | 3000 Kilograms (kg) |

| Warranty | 1 year |

| FOB Port | xiamen |

| Payment Terms | Telegraphic Transfer (T/T), Paypal, Western Union |

| Supply Ability | 200 Per Month |

| Delivery Time | 20 Days |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | 1 set in nude packge |

| Main Export Market(s) | Australia, North America, Eastern Europe, Western Europe, Middle East, Africa, Central America, South America, Asia |

| Main Domestic Market | All India |

Product Overview

Key Features

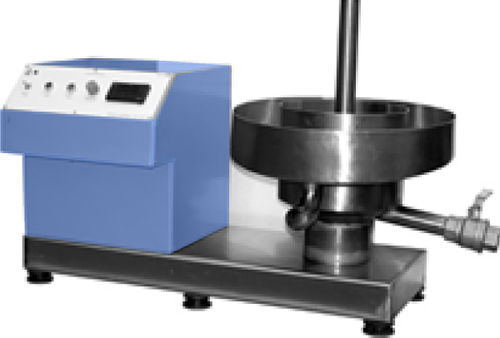

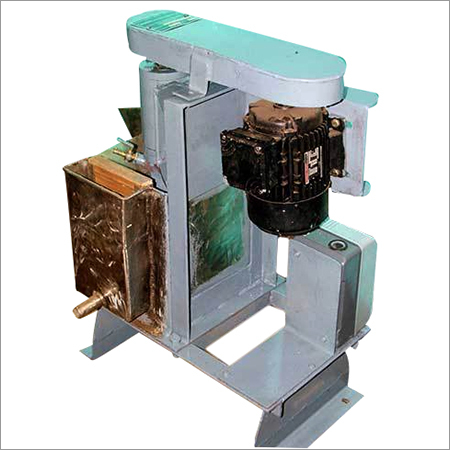

Product Introduction of Ore flotation machine

Flotation is mainly for solid-liquid or liquid-liquid separation. Large sum of micro bubbles produced by dissolving and releasing system adhere to solid or liquid particles with same density as waste water to make the whole float to the surface thus achieve the aim of solid-liquid or liquid-liquid separation.

Product Application of Ore flotation machine

Flotation Machine is applied for rough, fine and sweep separating process of ferrous metals, precious metals, nonmetallic minerals and nonferrous metals such as lead, copper, zinc, molybdenum, etc. This series flotation machine is with large inspiratory capacity inflow and low energy consumption. Every chute is levelly installed and performs three functions: inhaling air, inhaling ore pulp and flotation separation without accessories.

Working Principle of Ore flotation machine

(1) After intensively mixed, the pulp and medicaments are fed to the groove bottom of the first tank.

(2) When the impeller of the lead zinc flotation cells begins to rotate, negative pressure is formed, making the air and pulps at the bottom and middle part of the tank enter the mixing zone. The pulp, air and medicaments are then mixed in the mixing zone.

(3) As a result of the cenrifugal force, the blended pulps are lead to the mineralization area. The air is in full contact with the coal particle and forms mineralized discharged by the scraping tool. Finally, clean coal foam is produced by this Flotation cell.

(4) Coal particles that are not mineralized will be remixed, re-mineralized and re-separate through the recycle hole and the upper intake.

(5) The left pulp that are not sucked by the impeller enters intor the third tank after going through the process of the first tank, thus, lead zinc flotation cells

runs in cycle and discharges ore pulp through the tailing box of the Flotation cell.

Company Details

Focusing on a customer-centric approach, Jiangxi Victor International Mining Equipment Co.,Ltd has a pan-India presence and caters to a huge consumer base throughout the country. Buy Automotive Filters in bulk from Jiangxi Victor International Mining Equipment Co.,Ltd at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Distributor, Supplier

Employee Count

30

Establishment

2003

Working Days

Monday To Sunday

Related Products

More Product From This seller

Seller Details

Ganzhou, Jiangxi

Maja Liu

Address

Guzhang industrial park, Shicheng, Ganzhou, Jiangxi, 341101, China

flotation cell in Ganzhou

Report incorrect details