R.t.d. Studies In Packed Bed Reactor Apparatus - Borosilicate Glass Reactor Column, 20 Ltr Stainless Steel Feed Tank, Rasching Rings | Engineering Testing Equipment For Fluid Dispersion Analysis

Price: 500.0 INR / Piece

Get Latest Price

Minimum Order Quantity :

1 Piece

Brand Name :

Edutek

In Stock

Product Specifications

| Usage | Engineering Testing Equipment |

| Application | Engineering Testing Equipment |

| Product Type | R.T.D. STUDIES IN PACKED BED REACTOR APPARATUS |

| Packaging Details | Carton Box, Export Quality also Available |

| Main Export Market(s) | Asia, Middle East, Africa |

| Main Domestic Market | All India |

| Certifications | ISO 9001, 14001, CE |

Product Overview

Key Features

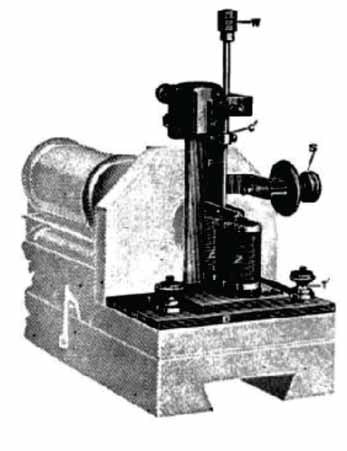

R.T.D. STUDIES IN PACKED BED REACTOR APPARATUS

Axial diffusion and dispersion of fluid in packed beds are important for design and operation of separation equipment and Chemicals reactors. The tracer technique, the most widely used method for the study of axial dispersion.

In stimulus response experimentation, we perturb the system using pulse input of tracer and then see how the system reacts or responds to this stimulus.

The analysis of the response gives the desired information about the system. The setup consists of a glass column packed with Rasching Rings and one feed tank. Water is fed to the reactor through liquid distributor, fitted at the bottom of the column.

Rotameter is provided to measure the flow of water. The flow rate can be adjusted by operating the needle valve provided on Rotameter. For understanding the R.T.D. characteristics, a special arrangement to inject tracer into the lower end of reactor, using a syringe, is provided. Samples can be taken periodically from the top outlet of reactor. Pressure Regulator & Pressure Gauge are fitted in the compressed air line.

Experimentation/Learning Objectives

To plot RTD curve for Packed Bed Reactor.

To determine the Dispersion No.

Utilities Required

Compressed Air Supply: 0.25 1 bar

Water Supply.

Floor Drain.

Floor Area Required: 1.0 m x 1.0 m.

Instruments, Laboratory Glassware and Chemicals required for analysis as per the system adopted.

Technical Details

Reactor Column: Material Borosilicate Glass

Packing: Rasching Rings, Material Borosilicate Glass. Size 8-10mm (approx.)

Feed Tank: Material Stainless Steel, Capacity 20 Ltrs.

Feed Circulation: By compressed air.

Flow Measurement: Rotameter.

Piping: Stainless Steel and PU pipe.

Pressure Regulator: 0-2 Kg/cm2

Pressure Gauge: Bourdon type 0-2 Kg/cm2

Stop Watch: Electronic

Arrangement is done to inject tracer into the lower end of reactor

Company Details

Manufacturer and Exporter of all type engineering lab equipment, civil engineering lab equipment, science lab equipment, soil testing lab equipment, concrete Testing Lab Equipment, Vocational Training Equipment, Teaching lab equipment, Pharmacy Lab Equipment, Mechanical Lab for engineering college, fluid mechanic lab for engineering students, etc

Business Type

Exporter, Manufacturer, Supplier

Employee Count

25

Establishment

1973

Working Days

Monday To Saturday

GST NO

06AEWPJ6896D1ZU

Certification

AN ISO 9001:2008

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 06AEWPJ6896D1ZU

Ambala Cantt, Haryana

Director-international Sales

Mr Vikas

Members since

11 Years

Address

Factory: 70, Edutek House, Main Road Vikaspuri, Industrial Area, Ambala Cantt, Haryana, 133006, India

chemical reactors in Ambala Cantt

Report incorrect details