Pvc Upvc Double Wall Corrugated Pipe Machine With Conical Twin Screw

Price: 30000 USD / Set

Get Latest Price

Minimum Order Quantity :

1 Set

In Stock

Product Specifications

| Type | 12-63MM |

| Material | PVC |

| Capacity | 40-60Kg/H Kg/hr |

| Computerized | Yes |

| Automatic Grade | Automatic |

| Control System | PLC Control |

| Drive Type | Direct |

| Screw Diameter | 12-63MM Millimeter (mm) |

| Weight (kg) | 4000 Long Ton |

| Dimension (L*W*H) | 6X0.75X1.2 Meter (m) |

| Color | Customized |

| Warranty | 1 year |

| FOB Port | Shanghai |

| Payment Terms | Telegraphic Transfer (T/T) |

| Supply Ability | 20 Per Month |

| Delivery Time | 45 Days |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | WOODEN CASE PACKING AND PLASTIC FILM |

| Main Export Market(s) | Africa, Middle East, South America |

| Main Domestic Market | All India |

| Certifications | CE,ISO |

Product Overview

Key Features

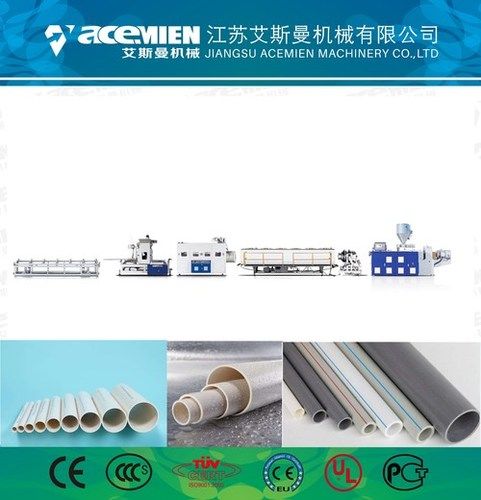

Plastic extruder AcA A MouldAcA A forming machine AcA A Cooling tank AcA A Cutter AcA A Stacker

The scope of diameter: (OD) A A 63mm-A A 250mm

PVC UPVC Double Wall Corrugated Pipe Machine With Conical Twin Screw 0

Double wall corrugated pipe introduction

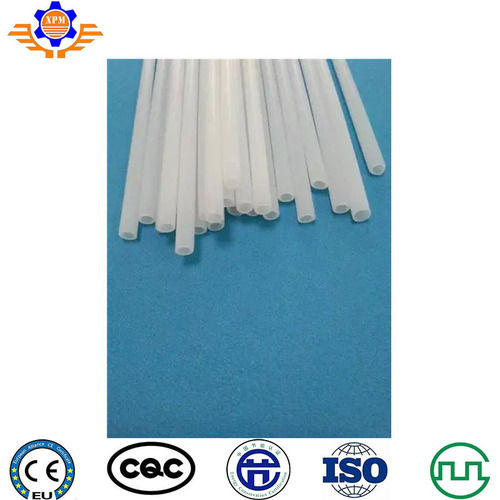

1) Double wall corrugated pipe (ODA A 63mm-A A 250mm) material is UPVC. the design of structure is new and reasonable.

2) Smooth inner layer and hollow corrugated outer layer composed.

3) It has many advantages, such as: good ability bearing external load, high strength, light weight, smooth inner wall, impact resistance, corrosion resistance, construction convenient, and low cost and so on.

4) The pipe adopts socket expanding and seal ring connecting which prevents expanding from hot and shrinking from cold.

5) Double wall corrugated pipe are widely used in highway, railway roadbed, the Mass Transit Railway engineering, waste landfill sites, tunnels, green belts, sports grounds and drainage area such as slope protection caused by high water content.

Double wall corrugated pipe extruder Features:

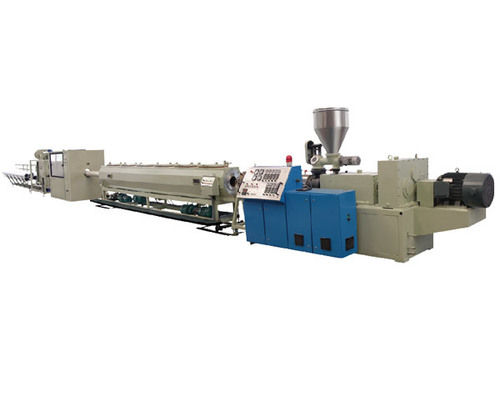

In order to meet the demand of plastic pipe market, our Company designed and developed this UPVC Double

Wall Corrugated Pipe Extrusion Line SBG 250 by absorbing advanced technology from foreign countries

plastic machinery industry.

This UPVC Double Wall Corrugated Pipe Extrusion Line is the latest study achievement in the plastic in the plastic extrusion field. This extrusion line is suitable for the high speed extrusion of UPVC material. UPVC Double Wall Corrugated Pipe Extrusion Line adopts one conical twin screw extruder directly extruding and forming technology, human-machine interface control system. It makes high automation degree, reliable quality and stable production become true. And this Corrugated Pipe production line wins our home and abroad customersAcA A good reputation.

Extruder: Equipped with forced fixed-quantity feeding system,High speed and efficiency conical twin screw extruder is specially designed for extrudidng PVC material,automatic temperature control system, vacuum exhaust system and automatic speed control system. This structure assures accurate controlling for the material temperature, plasticization stability and greatly improving corrugated pipe quality.

PVC UPVC Double Wall Corrugated Pipe Machine With Conical Twin Screw 1

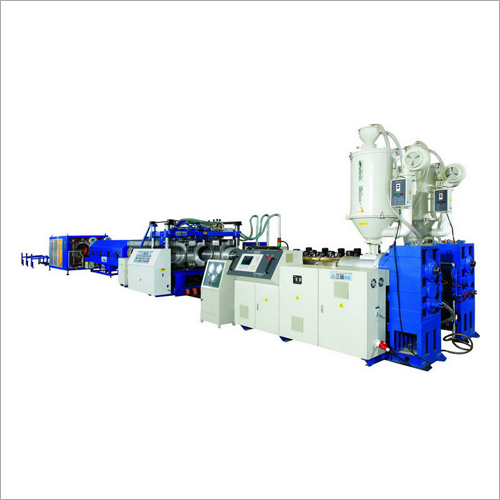

Corrugator: High performance vertical/shuttle corrugator ensure the pipe of good quality and high efficiency

Horizontal structure; Chain type transmission; Equipped with open water cooling system. This kind of design greatly increases the production speed. With special and accurate forming module; Cooling air and water system which guarantee the production speed fast. It greatly increases the production speed. Mold moving adopts advanced synchronous upper and lower mechanical drive system. It assures moving accuracy and plastic pipe quality stability. Advanced self-lubricating system makes the forming molds and mold plates abrasions minimize and greatly extend the service life.

Die head: Spiral type; Special structure design; Small volume and clean flow. It is composite die head and made of 40Cr, plating chrome and polishing. which makes the corrugated pipe inner and outer layer wall thickness even and forming stability.

Cutting machine: automatically cutting, Effective cutting, high speed, low noise and dustless cutting and so on many advantages.

Control system: this UPVC Double wall corrugated pipe production line adopts Siemens professional PLC control system, 15 "large colorful touch screen human-machine interface, high automation, reliable running, easy operation, remote communication function which can realize remote fault diagnosis and rule out the possibility.

Company Details

Xinda Precision Machinery Company has focused on the plastic machinery over 20 years with rich experience and strong technology support , our company is one of the key enterprises appointed by the China Ministry Light Industry. Our main products include carpet coating TPR TPE machine ; PVC pipe production line ; PVC WPC foam board production line machine ; PVC marble sheet extrusion line ; PE board sheet production line ; PVC imitation marble profile making machine ;PVC PC tile production line ; plastic floor making machine ; PE PP PPR pipe production line ; PVC ABS edge banding production line , PVC profile production line machine ; PVC lace gilding tableclothe production machine ; PVC lace cup mat coaster production machine ; PP PET strap production line ; TPR shoe welt making machine ; mixer, feeder etc.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

20

Establishment

1997

Working Days

Monday To Saturday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Zhangjiagang, Jiangsu

Vice General Manager

Mr John Yu

Address

Jinfen Town, Zhangjiagang, Jiangsu, 215600, China

pvc pipe extrusion line in Zhangjiagang

Report incorrect details