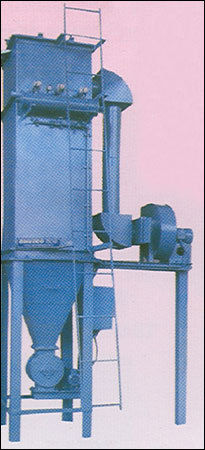

Pulse Jet Bag Filters - High-temperature Resistance Up To 240â°c | Multi-module Design For Optimal Gas Distribution, Customizable Filter Media, Low Can Velocity For Dust Re-entrapment Minimization

Price:

Get Latest Price

In Stock

Product Specifications

| Operating Temperature | 240°C |

| Operating Pressure | 1500 mmWC |

| Filter Media | Multiple options |

| Casing Material | Steel |

| Hopper Design | Optimized |

| Usage | Dust removal in various industrial processes, including cement, steel, sugar, chemical, and pulp & paper industries |

| Compliance | Relevant standards |

| Features | Dust removal, High efficiency, Low emissions, Reliable operation, Modular design, Easy maintenance |

Product Overview

Key Features

These bag filters are widely used in utility boilers, cement, steel, sugar, chemical and pulp and paper industries.

The bag filters are sized and designed to maintain a suitable air to cloth ratio depending on the application.

Multi module bag filters are manufactured with properly designed inlet and outlet plenums for even gas distribution across all the modules. To ensure the uniform gas distribution, CFD studies are carried out using software tools like FLUENT, ANSYS etc.

The operating temperatures are ranging from ambient to 240 Deg. C. The operating pressures ranges from 500 to 1500 mm W.C.

Filter bag:

The filter bags are manufactured from wide variety of filter media/fabric with required surface treatments to suit different applications and characteristics of dust / gas to be handled by the bag filter.

Casing:

The casing of the bag filters is optimally designed to house the filter bags and accurately fabricated to obtain optimum performance of the system. The bag to bag distance and the casing is sized to maintain low CAN velocity to minimize re-entrainment of collected dust.

Hoppers:

Hoppers are designed with a valley angle based on the dust characteristics in such a way that the collected dust gets discharged in to the dust handling equipment easily.

Company Details

Focusing on a customer-centric approach, Clair Engineers Pvt. Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Pollution Control & Monitoring Equipment in bulk from Clair Engineers Pvt. Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

25

Establishment

1994

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Hyderabad, Telangana

Purchase Manager

Ms Savitha

Address

K.k House', Plot No. B-35/1, Lane Adjacent To Andhra Bank, Industrial Estate, Sanath Nagar, Hyderabad, Telangana, 500018, India

pollution control equipment in Hyderabad

Report incorrect details