Pulp Moulding Process Type And Egg Use 6 Hole, 12 Hole Paper Egg Tray Production Line

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Variable |

| Capacity | 1000-10000Pcs/Hr |

| Power | Variable |

| Dryer Type | Multiple |

| Moulds | Customizable |

| Warranty | 1 Year |

| Features | High Yield, Eco-Friendly, Pulp Moulding, Egg Tray Making, Waste Recycling, Customizable, High Return |

| FOB Port | Tianjin Port |

| Payment Terms | Telegraphic Transfer (T/T), Cash in Advance (CID) |

| Supply Ability | 300 set Per Year |

| Delivery Time | 20-60 Days |

| Sample Policy | Free samples are available |

| Packaging Details | standard export package |

| Main Export Market(s) | South America, Middle East, Africa, Western Europe, Central America, Asia, Eastern Europe, North America |

| Main Domestic Market | All India |

Product Overview

Key Features

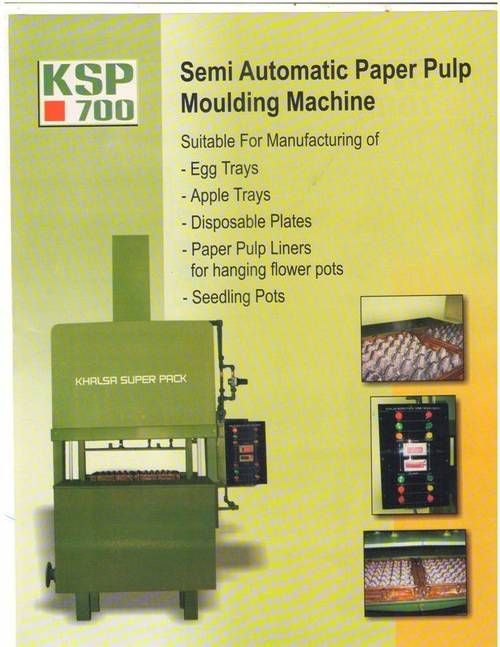

Zengtuo paper egg tray making machineA is used to produce paper egg tray,

apple tray and other trays. The main working process of paper egg tray machine is composed of pulping system, forming system and drying system. Paper tray making machine is mixing the waste paper and water. When it reaches the certain concentration, the egg tray pulp can be conveyed to forming machine. When it forms a paper egg tray, the egg tray paper needs to dry because the paper egg tray has some water after forming. Then, you can pack the paper egg tray after drying.

And it is also a waste recycling machines,the raw material use general waste paper, like old book, oldA newspaper ,abandoned carton and so on .

Egg carton trays making machineA is very environmentally friendly andA Safety,it A is in line with the needs of the development of modern society .High yield and high return.

Our egg tray machine factory can produce different dryers to match the egg tray production line according to customers' condition and requirement so that get the best and high effective production

1) Egg Tray Machine without dryer (sun dry).

Without dryer also means natural drying, sun dry.

It need large space to place the frame with pallats to drying the egg tray in the sun.

This drying method is energy saving, suitable for small capacity egg tray production line.

2) Egg Tray Machine with Traditional Brick Civil Dryer(Conveyor Belt Dryer).

Civil dryer also means traditional dryer, brick dryer and conveyor belt dryer.

It need fuel for drying room to dry the egg trays, the fuel can be coal, gas, diesel etc.

This drying method is economical and practical, high effective, it is a kind of widely used egg tray production line.

3) Egg Tray Machine with Metal single layer dryer.

Fully automatic egg tray Production Line.

Metal out layer, beautiful and easy installation.

4) Egg Tray Machine with Metal multi-layer dryer.

Fully automatic egg tray production line.

Multi layer drying is 6 layers, the least workplace needed, Easy installation, production directly.

9. FAQ

A. What kinds of machines do you produce?

We produce

(1)pulp moulding machines,egg tray machines,egg packing machines,egg box/carton machines, fruit tray machines,industrial machines, seeding tray machines and the whole production line etc.

(2)all kinds of moulds ,such as egg tray moulds,egg box/carton moulds, fruit tray moulds,seeding tray moulds,industrial moulds etc.

(3)drying line

B.A What capacity per hour do you offer ?

Our machinesa capacity is from 1000pcs/hr to 10000pcs/hr.

C. Do your products come with a warranty ?

Yes , we have one year warranty according the international practice.

D. Can I customize this kind of product from your factory?

Yes ,we offer custom made service to our customers, you need to provide us some samples,such as photos,dimensions etc.

E. Can you give me a low price?

Yes,we are the manufacturer, at the same moment we guarantee the quality, we will give you a lower price.

F. How to install?

The seller dispatches engineers to buyera s factory. Buyer should help installation.

Seller is responsible for installation, testing and training for 30 days, the buyer should insure the safety of the engineers.

Company Details

Business Type

Exporter, Manufacturer

Employee Count

60

Establishment

2008

Working Days

Monday To Friday

Payment Mode

Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Shijiazhuang, Hebei

Sales Manager

Mr Alice Lee

Address

Room 805, Block A, Jinhe International Business Bldg., Zhengding County, Shijiazhuang, Hebei, China

pulp moulding machine in Shijiazhuang

Report incorrect details