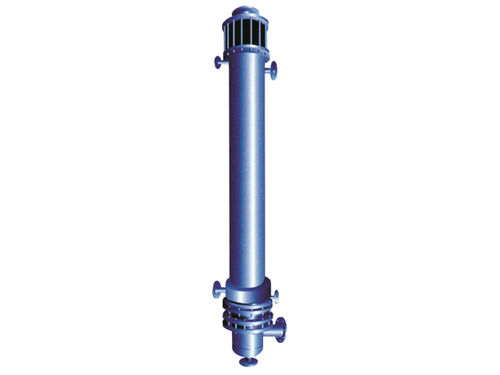

Carbon Steel Ptfe Anti-corrosion Liner

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Carbon steel |

| Corrosion Protection | Yes |

| FOB Port | Qingdao |

| Payment Terms | Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union |

| Delivery Time | 20 Days |

| Packaging Details | Boxes,pallet |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa |

| Certifications | ISO9001 : 2015 Quality Management Systemi1/4OEISO14001 : 2015 Environment Management Systemi1/4OEOHSAS 18001:2007 Occupational Healthy and Safety Management System |

Product Overview

Key Features

As a quality-oriented organization, we are focused to make, export and supply of PTFE Anti-Corrosion Liners. PTFE spraying technology overcame the problems of using limitation for PTFE lined process caused by shape restriction.Any shape of equipment,spare parts can be all sprayed and processed,it is the upgraded products of traditional PTFE lined product.Using special process to make the anti-corrosion layer that thickness is 0.5-1mm on the surface of the equipment,the coating layer has the characteristics following:

There is high adhesion between the coating layer and metal layer,and it is impossible to remove by external forces.It solved the problems of easy to bubbling and falling off,it is more obviously in the condition of vacuum or temperature changes frequently.

It has excellent performance of anti-stick and temperature resistance,so it is widely used in rubber industry.

Design pressure:1.60MPa,can be used under negative pressure.

Design temperature:-60~220a ;

Corrosion resistance:It will not be corroded by any medium except strong oxidizer.

PTFE Steel-plastic composite pipe,steel-plastic molded composite parts

PTFE steel-plastic composite pipe and spare parts are made of high-quality F4 pipe,using special processing technology to make the steel pipe and the plastic pipe completely tightly combined.It has reliable and excellent corrosion resistance to transport the fluid under condition of strong corrosion and high temperature,it cannot be replaced by other kinds of pipe.

Steel-plastic molded composite parts include elbows, tees, reducers, etc. It using advanced technology such as one-time molding to ensure corrosion resistance and anti-aging properties.

Design pressure:1.6MPa,can be used under negative pressure.

Design temperature:-60~250a ;

Corrosion resistance:It will not be corroded by any medium except strong oxidizer.

PTFE Rolling lining, lining technology

Using the technology of mature rolling lining equipment, hot-melt welding method and other process technology to produce any size F4 lining anti-corrosion equipment according to user requirements, lining thickness is 2-15mm, widely used in tanks, towers and containers etc., waste enamel tank can also be re-used after being fixed..

There is high adhesion between the coating layer and metal layer,and it is impossible to remove by external forces.It solved the problems of easy to bubbling and falling off,it is more obviously in the condition of vacuum or temperature changes frequently.

It has excellent performance of anti-stick and temperature resistance,so it is widely used in rubber industry.

Design pressure:1.60MPa,can be used under negative pressure.

Design temperature:-60~220a ;

Corrosion resistance:It will not be corroded by any medium except strong oxidizer.

PTFE Steel-plastic composite pipe,steel-plastic molded composite parts

PTFE steel-plastic composite pipe and spare parts are made of high-quality F4 pipe,using special processing technology to make the steel pipe and the plastic pipe completely tightly combined.It has reliable and excellent corrosion resistance to transport the fluid under condition of strong corrosion and high temperature,it cannot be replaced by other kinds of pipe.

Steel-plastic molded composite parts include elbows, tees, reducers, etc. It using advanced technology such as one-time molding to ensure corrosion resistance and anti-aging properties.

Design pressure:1.6MPa,can be used under negative pressure.

Design temperature:-60~250a ;

Corrosion resistance:It will not be corroded by any medium except strong oxidizer.

PTFE Rolling lining, lining technology

Using the technology of mature rolling lining equipment, hot-melt welding method and other process technology to produce any size F4 lining anti-corrosion equipment according to user requirements, lining thickness is 2-15mm, widely used in tanks, towers and containers etc., waste enamel tank can also be re-used after being fixed..

Related Products

More Product From This seller

Company Details

Shandong Head Co., Ltd is a professional company specialized in cellulose ether production combining scientific research, development, sales and exporting business, adopting originals & patent newA a one stopa A method.Main products of Head include Cellulose Ether series,Graphite Chemical Equipment,Vegetable Capsules,Trimethyl Orthoacetate and Diacetone Acrylamide.It offers nearly a hundred types of Cellulose Ether products,making it one of the leading enterprises in China Cellulose Ether industry,building a professional and dedicated leader image of the rapid and standardization process of the industry.Cellulose ether products with annual capacity reaches 22900 MT. The company produce pharmaceutical and food grade products strictly according to GMP requirements. It can comply with USP, EP and CP standard,etc. The domestic sales cover more than 20 provinces and cities in China. The international sales cover more than 60 countries and areas including Europe, United States, Middle East, South East Asia, Japan, Korea, etc. Shandong Head has been one of the top cellulose ether manufacturers all over the world.

Business Type

Exporter, Manufacturer, Supplier, Producer

Employee Count

1280

Establishment

1992

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Certification

ISO9001,ISO14001,OHSAS 18001 etc.

Explore Related Categories

Report incorrect details