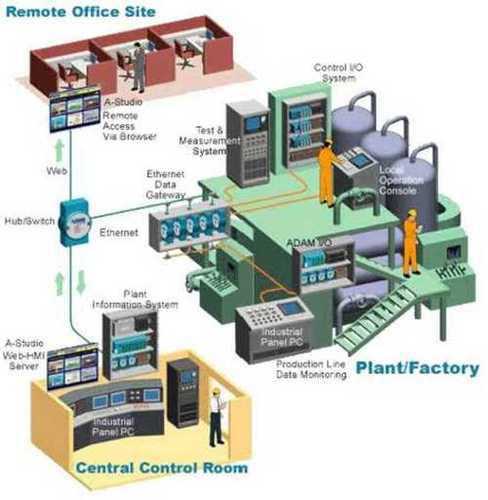

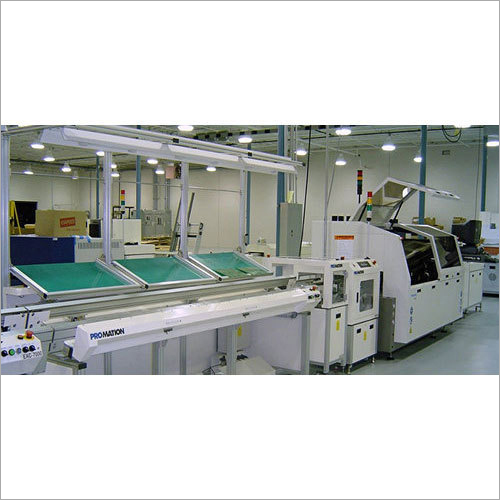

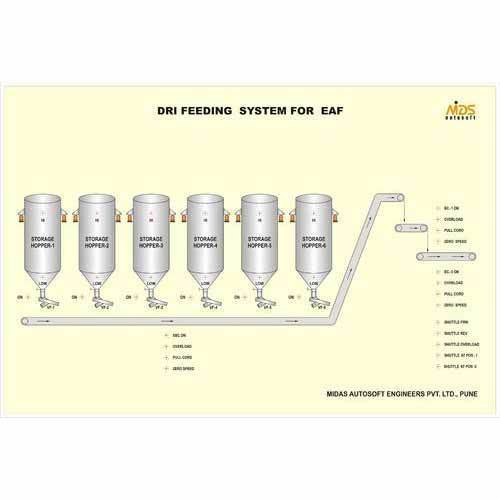

Process Automation System - Advanced Networked Control For Glass, Ceramics, Chemicals, Steel, Pharmaceuticals | Automated Monitoring, Real-time Data Analytics, Manual Override Capability

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Variable |

| Power | 220V |

| Sensors | Multiple |

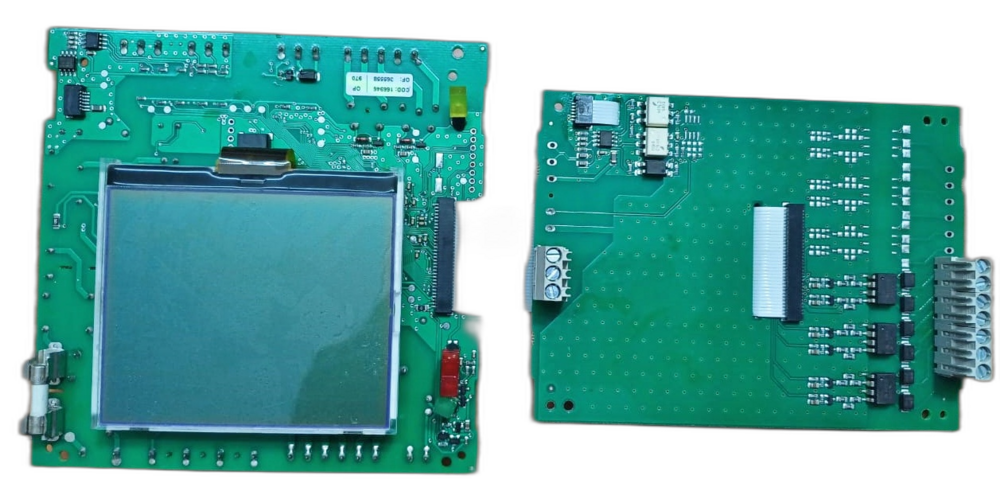

| Controllers | PLCs |

| Network | Ethernet |

| Software | SCADA |

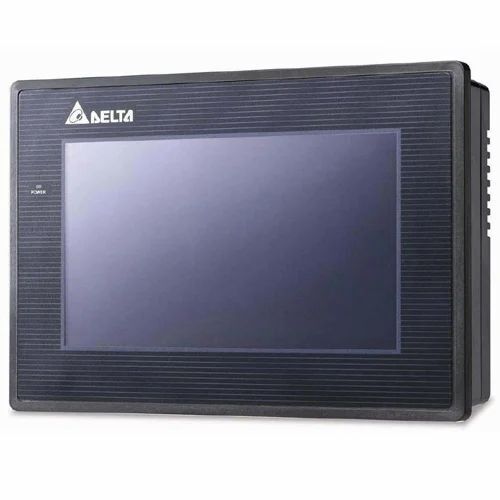

| Features | Automated control, Improved efficiency, Enhanced safety, Data analysis, Remote monitoring, Real-time tracking, Reduced downtime, Easy integration |

Product Overview

Key Features

The background and technology In the absence of process automation, plant operators have to physically monitor performance values and the quality of outputs to determine the best settings on which to run the production equipment. Maintenance is carried out at set intervals. This generally results in operational inefficiency and unsafe operating conditions.

Process automation simplifies this with the help of sensors at thousands of field instruments around the plant that collect data on weighing, Batching, temperatures, pressures, flows and so on. The information is stored and analyzed on a computer and the entire plant and each piece of production equipment can be monitored on a large screen in a control room. Plant operators can manually override the process automation systems when necessary.

Company Details

Business Type

Manufacturer, Supplier

Employee Count

60

Establishment

2005

Working Days

Monday To Sunday

GST NO

27AAECM2414R1Z5

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAECM2414R1Z5

Pune, Maharashtra

Manager

Mr. N B B Thite

Members since

3 Years

Address

677/B, Behind Siddhivinayak Hospital, At/P Velu, Tal. Bhor, Dist. Pune, Pune, Maharashtra, 412205, India

industrial automation system in Pune

Report incorrect details