Precious Micro Classifier Bag Size: 10x14

Price:

Get Latest Price

In Stock

Product Specifications

| Model | PMS 150,PMS 300,PMS 620,PMS 1T |

| Capacity | 150 kg/hr,300 kg/hr,620 kg/hr,1 T/hr |

| Power | 3 HP,5 HP,10 HP,15 HP |

| Material | Minerals |

| Particle Size | 10-100 micron |

| Usage | Separating dry chemicals and minerals to get fine powder. |

| Finish | Corrosion resistant |

| Features | Fine powder, Low power, High fluency, Corrosion resistant |

Product Overview

Key Features

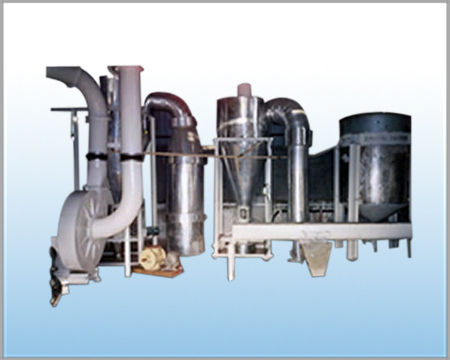

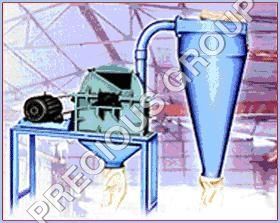

Precious Micro Classifier/Micro Sizer

Backed by strong expertise & knowledge, we manufacture and present best quality Precious Micro Classifier/Micro Sizer. Our clients can avail from us a wide range of machine that is renowned for its low power consumption, high operational fluency and corrosion resistant surface. Our machines are developed incorporating cutting advanced methodology, which ensures their optimal performance. We are offering this prominent quality Precious Micro Classifier/Micro Sizer to our clients at cost effective prices. The machine is used to filter the the dry chemicals and minerals in order to get a fine powder.

Further Details:

These classifier are being developed to operate dry powder at a very final stage usually used where 10 100 micron particles are required to be separated but in some cases it separate even one micron particles.

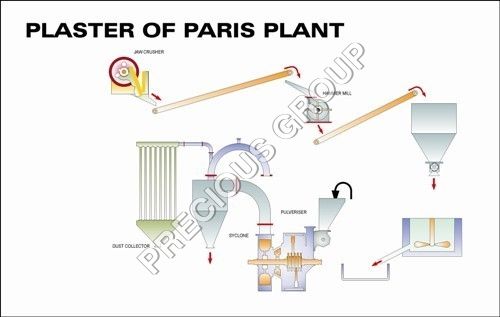

In this classifier material is throne inside the classifier with air pressure which moves centrifugly in the inner chamber of the classifier. There is a specially designed rotor which through out bigger particles to the paraferry of the chamber while finer move towards the center due to the suction pressure created at the center of rotor from the center fine particles move pneumatically to the cyclone and get collected at the bottom of cyclone. The big/ course particle which stick to the wall of the chamber comes down by gravity and throughen out of the chamber. Hence fines and coarse particles are being separate; the cut off point of separation depends very much on the speed of rotor. Hence to get a proper cut off point, speed of the rotor has to be changed with the help of variable speed drive. This is the best system to classify/ separate different particles of micro fine powder.

| Model

| Capacity

| Power Required

|

| PMS

| 150 kg/hr approx

| 3 H.P |

| PMS

| 300 kg/hr approx

| 5 H.P

|

| PMS

| 620 kg/hr approx

| 10 H.P

|

| PMS

| 1 T/hr approx

| 15 H.P

|

The production capacity and H.P depends on the physical properties and particle size of the material and are subject to variation in all the above machines.

Please note that the capacity shown above is that the light density of 1.1 gm/cm2 and fineness of 100 mesh (150 micron). The production capacity will change very much with the change of density and fineness of the material even other factors affect the production of the classifier.

Application

Separating dry chemicals and minerals in the high range of the fineness say found 100 mesh (150 micron) to 1500 mesh (10 micron).

Company Details

Focusing on a customer-centric approach, Precious Mach Tech has a pan-India presence and caters to a huge consumer base throughout the country. Buy Plant & Machinery in bulk from Precious Mach Tech at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

30

Establishment

1988

Working Days

Monday To Sunday

Payment Mode

Cash Against Delivery (CAD), Cash Advance (CA)

Certification

ISO 9001-2000

Related Products

More Product From This seller

Seller Details

Kheda, Gujarat

Proprietor

Mr. Pravin Agarwal

Address

Plot 554, Kanera Gam, Nh 8, Opposite Gokulesh Petrol Pump, Kheda, Gujarat, 387540, India

Plant & Machinery in Kheda

Report incorrect details