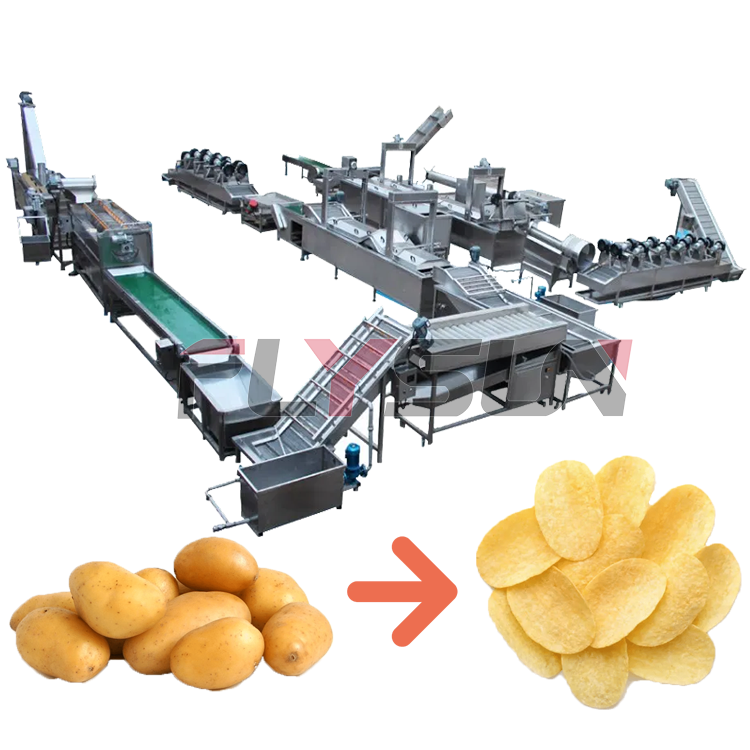

Potato Chip And French Fries Fryer - Capacity: 100-3000 Kg/hr

Price: 4400000.0 INR

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Heating Method | electricity |

| Frequency | 50-60 Hertz (HZ) |

| Features | to make potatao chips,french fries |

| Speed Mode | Variable |

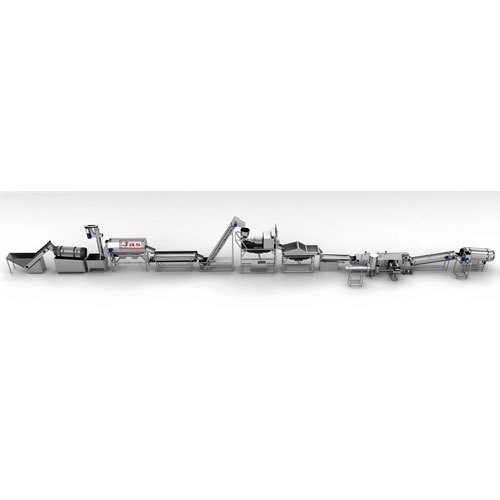

| Product Type | Potato Chip and French Fries Fryer |

| General Use | Industrial |

| Material | Stainless Steel |

| Type | Food Processors |

| Capacity | 100-3000 Kg/hr |

| Weight (kg) | 900 Kilograms (kg) |

| Product Shape | Chip |

| Computerized | No |

| Automatic | Yes |

| Control System | Manual |

| Dimension (L*W*H) | 4000*1100*2200 Millimeter (mm) |

| Feature | ECO Friendly, Low Noice, Lower Energy Consumption, High Efficiency |

| Color | White |

| Warranty | 1 |

| Payment Terms | Cash in Advance (CID), Cash Advance (CA), Others |

| Supply Ability | 20 Per Month |

| Delivery Time | 1 Week |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Packed In As per Industry Standard |

Product Overview

Key Features

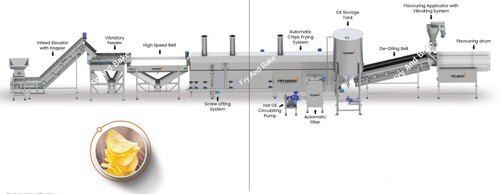

1.Process capacity including input capacity and output capacity and process flow can be customized according to your need.

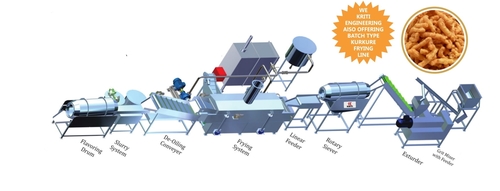

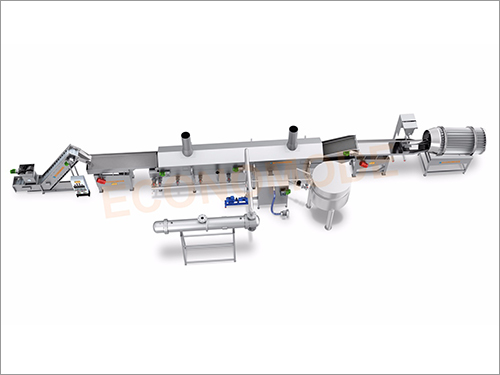

2.About plant scale, we can do full automatic line (finished capacity 100kg/h to 2000kg/h), it can improve production efficiency and save manpower, it is very suitable for the factory and business with a certain scale and starting business.

3.Small scale semi-automatic production line(finished capacity 30kg/h to 300kg/h) and its scale is not so big like full automatic line and ask less manpower, its cost is lower than full automatic line, its production method is very flexible, and suitable for a small-scale business or a company that has just begun to enter the industry.

4.All equipment in the production line is made of 304 stainless steel.

5.Heating method: Electric heating, Gas heating or Electricity heating and gas heating both in one.

6.The size of French fries and the thickness of potato chips are adjusted.

7. We can design floor plan of complete line you need depending on your area' s size.

A1. The production time of the machine will take 30 working days. The production will start after receiving the deposit, and the final payment shall be paid before delivery. Contact me for more details in quotation.

Q2. What about the Warranty?

A2. We are committed to every food line before delivery through professional commissioning debugging to ensure that the machine is best for you. And solemnly promise you can machine warranty for one years, Long-term to provide an after-sale spare parts service

cost price.

Q3. Do you provide equipment operation training?

A3. Yes. We can send professional engineers to the working site to guide the installation, adjustment, and operation training. All of our engineers have passports.

Q4. Can I visit your factory?

A4. Yes. Many domestic and international customers visit our factory every year. Our company is located in Zhengzhou City, Henan province, China, you can come here by air or train.The nearest airport is Zhengzhou Xinzheng International Airport, and the Airport Code is CGO.We will pick you up at the airport. Welcome to visit our factory.

Company Details

Flysun Machinery is located in Gongyi City, Henan Province, founded in 2011. Flysun Machinery is a technology-based enterprise integrating R&D, manufacturing, sales and after-sales.

We has built a first-class modern production base and a global sales and after-sales network. Our customers are located all over the country and successfully exported to Malaysia, Indonesia, South Korea, the United States, Britain, Australia, Bangladesh, Russia, India, Africa, Europe, Southeast Asia and other countries.

Business Type

Exporter, Manufacturer

Employee Count

150

Establishment

2012

Working Days

Monday To Sunday

Certification

CE

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Zhengzhou, Henan

Online Operations Specialist

Mr. Ye Lu

Address

N Cube B8-5,58 Yinlan Road Zhengzhou, Henan, 450000, China

Report incorrect details