Plate And Frame Filter Press - Color: White Black

Price:

Get Latest Price

Minimum Order Quantity :

1

Brand Name :

Teknik

In Stock

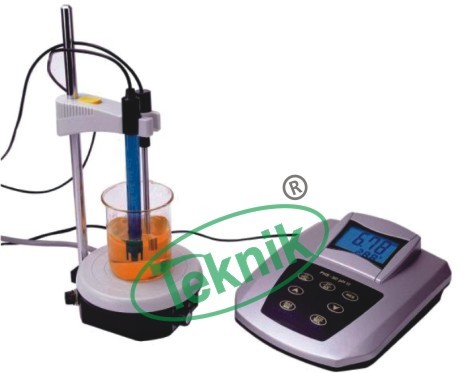

Product Specifications

| Frequency | 50 Hertz (HZ) |

| Power Supply | Electric |

| Color | White Black |

| Material | Mild Steel |

| Voltage | 230 Volt (v) |

| Usage | Laboratory |

| Payment Terms | Cash Advance (CA), Telegraphic Transfer (T/T), Cheque, Letter of Credit (L/C), Cash in Advance (CID) |

| Supply Ability | 100 Per Week |

| Delivery Time | 1 Week |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | carton box, export quality also available |

| Main Domestic Market | All India |

| Certifications | ISO 9001, 14001 ,CE |

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

25

Establishment

1973

Working Days

Monday To Saturday

GST NO

06ACMPJ7244B1ZS

Certification

ISO 9001 : 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 06ACMPJ7244B1ZS

Ambala Cantt, Haryana

Ceo

Mr. Vikas

Members since

13 Years

Address

Plot No. 73, Vikaspuri, Industrial Area, Ambala Cantt, Haryana, 133001, India

frame filter press in Ambala Cantt

Report incorrect details