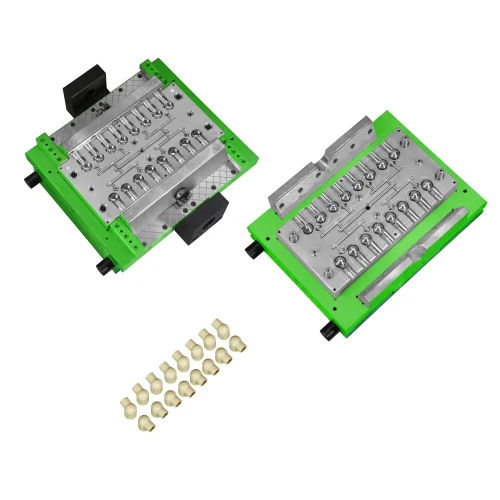

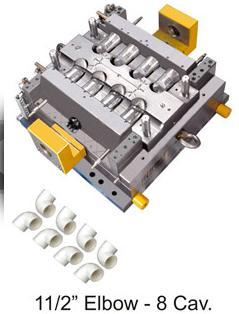

Pipe Fitting Molds And Dies Tee Shaping Mould From 1-2 Inch To 48 Inch

Price: RANG USD / Piece

Get Latest Price

Minimum Order Quantity :

1 Piece

In Stock

Product Overview

Key Features

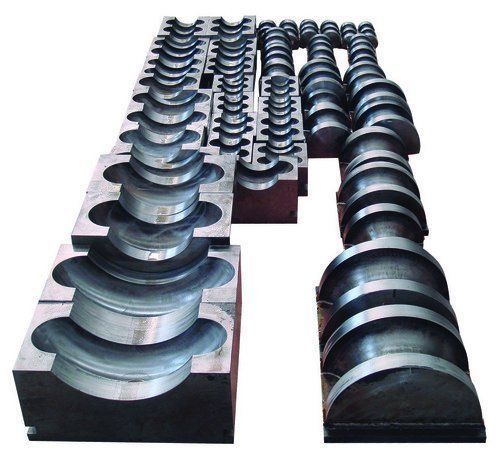

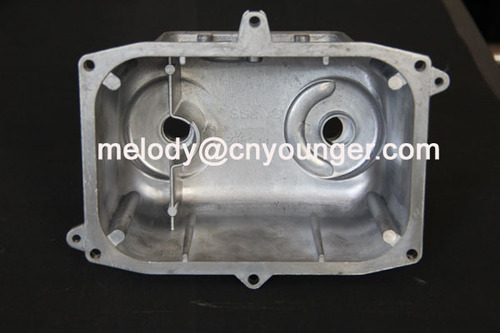

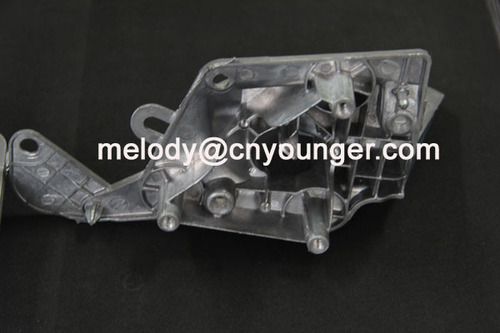

And the mandrel and All size Pipe Fitting Mould of Hot induction CS steel pipe bending machines material used in our factory has the characteristics of wear resistance, bending resistance and strong impact resistance, and the surface is bright and clean, suitable for the extrusion of copper, iron, aluminum, zinc, stainless steel and other metals.

Advantage of All size Pipe Fitting Mould of Hot induction CS steel pipe bending machines are as follows:

*High hardness and abrasion resistance surpasses the die steel, and does not strain the surface of the machined part.

*Compared with steel molds, it has good thermal conductivity and does not stick to molds, which can ensure uniform mold *temperature distribution during work, will not cause mold cracks due to local high temperature, and will not cause cold sweat, *exfoliation, and wrinkles in stretched products. phenomenon.

*Economic and practical, long life of core rod material.

*The core rod material processing technology is simple. Compared with steel molds, no direct heat treatment is required for direct polishing. Therefore, the heat treatment cost is reduced, the mold processing time is shortened, and the number of stretching times can be reduced and the cost of the mold can be reduced.

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company, Wholesaler, Producer

Employee Count

50

Establishment

2011

Working Days

Monday To Sunday

Payment Mode

Letter of Credit at Sight (Sight L/C)

Certification

ISO 9001:2008

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Cangzhou, Hebei

Manager

Mrs Lemon

Address

905 of One World Business Center, Cangzhou, Hebei, 061000, China

elbow moulds in Cangzhou

Report incorrect details