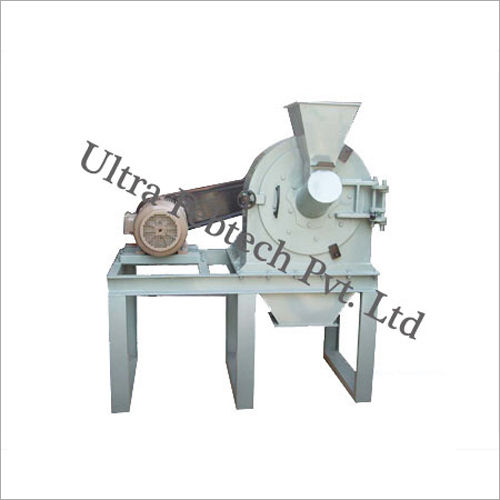

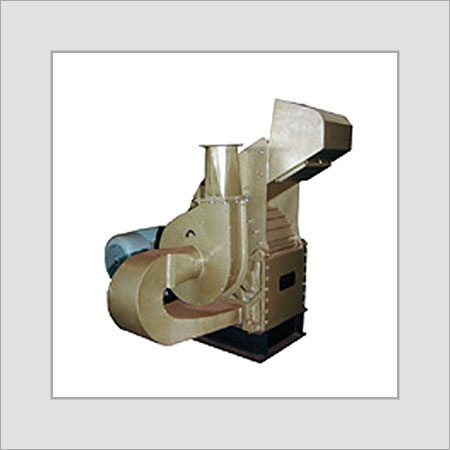

Pin Mills

Price:

Get Latest Price

In Stock

Product Specifications

| Feed Material | Centre Rotor |

| Screen Drum | Around Rotor |

| Fineness | 150 Mesh |

| Feeding | Manual/Hopper |

| Pins | L&T Type |

| Moc | Ms/Ss |

| Construction | Vibration Free |

| Features | Fine Powder, Less Power, Easy To Clean, Easy Operate, Less Space, Sturdy Build, Vibration Free |

Product Overview

Key Features

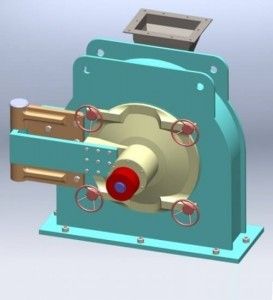

The FEED MATERIAL is FED into CENTRE of ROTOR and is conveyed to the PERIPHERY through series REATER PLATE, thus gradually reducing to find powder. SCREEN DRUM fitted around ROTOR, permits ground material of desired FINENESS to come out of the MILL for collection.

IMPORTANT TECHNICAL INFORMATION ON PIN MILLS:

PREMIUM PIN MILL is specially designed pulverized to deal efficiently and economically with a wide range of materials to grind them to predetermined fineness from COARSE to FINE POWDER up to 150 MESH (100 Micron) and above.

The grinding operation is effected through beating, shearing, crushing and auto collision of material. Feeding is manually for SMALL MILLS and for MEDIUM and LARGE CAPACITY MILLS, either HOPPER with HORIZONTAL GATE VALVE with rack & pinion is provided or SCREW FEEDER with VARIABLE SPEED DRIVE. This will give uniform and controlled FEED into the MILL.

SALIENT FEATURES:-

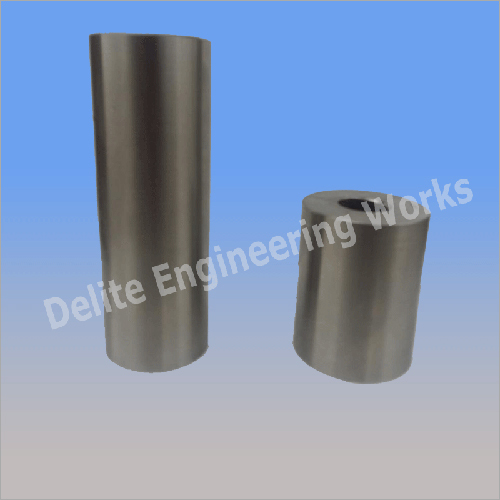

* L & T Type Pins.

* Pneumatic Conveying can be offered.

* MOC In MS / SS wear parts /SS Complete

* Round Pins in stator and or Rotor with FINE PITC.

* Whizzer Type PIN MILL (Screen less) can be provided.

* More out put than conventional Mill

* NARROW BAND of fineness

* Final product cool and smooth

* Less Power consumption

* OCCUPIES LESS SPACE

* RAPID & ADEQUATE ejection of pulverized material from all over the screen.

* Allows FEED MATERIAL with higher percentage of FAT and MOISTURE.

* STURDY & VIBRATION FREE CONSTRUCTION.

* Easy to CLEAN & Easy to Operate.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

50

Establishment

1985

Working Days

Monday To Sunday

GST NO

24AAACP7064N1Z4

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AAACP7064N1Z4

Ahmedabad, Gujarat

Marketing Engineer

Mr Visakh Nair

Members since

3 Years

Address

No. 2009, Phase-IV, Gidc, Vatva, Ahmedabad, Gujarat, 382445, India

pin mill in Ahmedabad

Report incorrect details