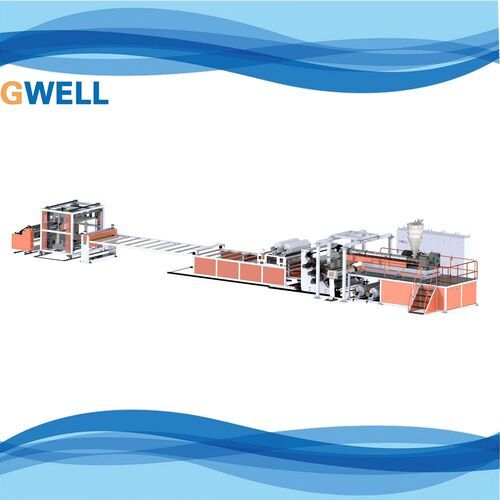

Pet Sheet Extrusion Production Line - Apet, Petg, Rpet | Automatic Operation, 1000 Kg/hr Capacity, Computerized, Multifunctional Design

Price:

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Type | PET Sheet Extrusion Line |

| Capacity | 1000 Kg/hr |

| Computerized | Yes |

| Automatic Grade | Automatic |

| Screw Diameter | 150/130/95/85 Millimeter (mm) |

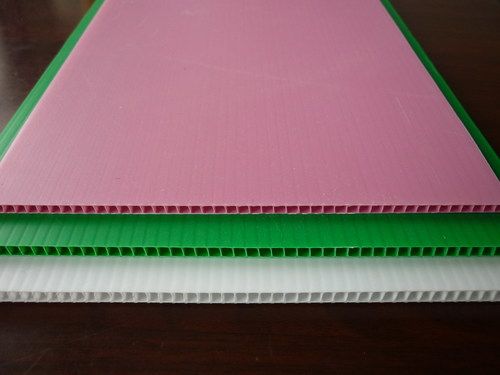

| Color | Customizable |

| Warranty | 1 Year |

| Supply Ability | 300 Per Year |

| Delivery Time | 4 Months |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East |

| Main Domestic Market | All India |

Product Overview

Key Features

Classification of PET sheet extrusion production line:

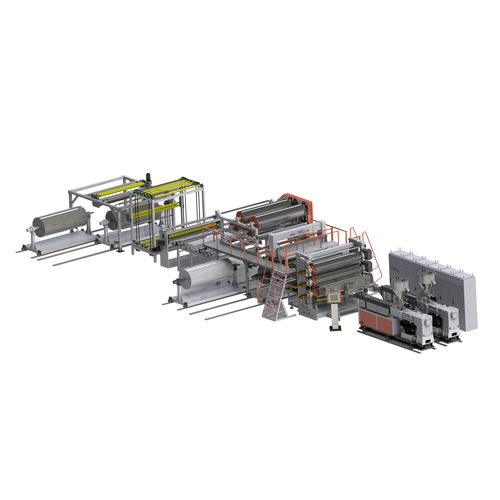

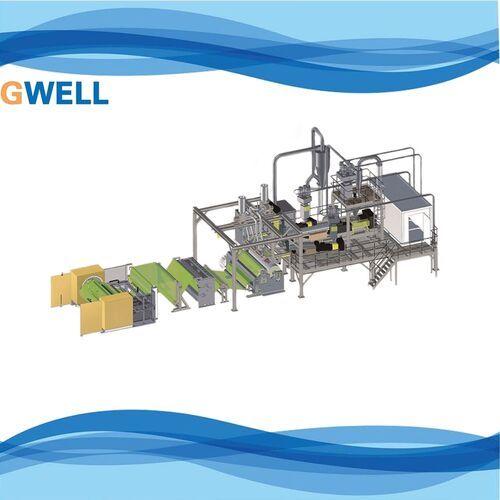

1. Single screw production line for PET sheet: single screw extrusion production line for APET, PETG and CPET sheet is the most mature project with the most stable production at present. Generally, single extruder production line or twin-extruder production line is adopted and GWELL uses the latest technology to increase the general efficiency by 30%.

2. PET sheet single screw exhaust production line: this machine only needs to crystallize PET, and does not need to dry. Its advantages: low energy consumption, simple process, convenient equipment maintenance, and can ensure the blister 18CM deep cup.

3. The PET sheet twin-screw exhaust line (free from dry and crystallization) : GWELL launched PET sheet twin-screw exhaust line without drying and crystallization which has the advantages of low energy consumption, high efficiency.This machine is GWELL's continuous improvement upgraded products , and its central vacuum system has been upgraded. The original roots - water ring pump group upgrades to roots - rotary vane pump, which can make the vacuum degree reach 10 pa, or less. Meanwhile by using PET special alloy steel thin-wall roller unit can increase the cooling efficiency, so as to increase output, improve product toughness and transparency. GWELL's independently programmed operating system ensures that the device is user-friendly and easy to operate.

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Supplier, Trading Company

Employee Count

500

Establishment

2010

Working Days

Monday To Saturday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Beijing, Beijing

Sales Engineer

Ms Vivian Gwell

Members since

2 Years

Address

No. 69, Hongrong Road, Chongchuan District, Natong City, Beijing, Beijing, 000000, China

Report incorrect details