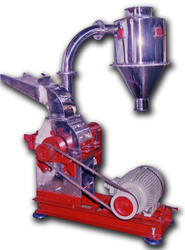

Sf Pearl Mill - Stainless Steel 304, 46x46x88 Cm | 40 Ltrs Capacity, Double-walled Cooling Jacket, Versatile Grinding Discs For Viscosity Range 50-5000 Cps

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel, Rubber |

| Dimensions | Variable |

| Speed | Variable |

| Ink Type | Food Grade |

| Power | Variable |

| Weight | Variable |

| Print Lines | 1-3 |

| Features | Easy To Use, Durable Design, Cost Effective, Versatile Printing, High Precision, Low Maintenance, Reliable Performance |

Product Overview

Key Features

SF PEARL MILL

S.F. PEAR MILL suitable for grinding low medium high viscosity material between 50 CPS and 5000 CPS Thixotropics and products with highly pigmented system.

Body

This machine will have the following items. Sturdy Mild Steel Heavy duty Plate frame Body of 10mm thk for the Mill size 46Aca A x 46Aca A x 88Aca A height.

Grinding Disc

Grinding Disc will be of Polypropylene having 10 Nos of Disc for Pigment Grinding (Water Based). Or Range Of Grinding Disc Available Will Be Of Special Wear-Resistant Steel, Hardened Chrome Steel Discs, Stainless Steel (304 Or 316), Hastelloy C , Polyurethane , UHMW Polyethylene , Polyamide (NylonA AR).

Main Shaft

Main Drive Shaft will be of 60mm Dia material of construction will be Stainless Steel 304.

Grinding Container

Double walled Cooling Efficiency Is Enhanced Through The use Of a Two-Zone Spiraled Jacket. The Spiral Design Creates These Desired Effects: cooling to the Entire Chamber; Greater Temperature Control Due To Increased Surface Area; And Reduced Pressure Drop by the Use of Two Inlet and

Sealing

Shaft sealing is carried out by a single-action mechanical seal with rotor and stator of Tungsten Carbide. Rinsing an of the mechanical seal is provided by a glycerin-flow closed circuit system by a PTFE Lip-seal, glycerin also water Aca a cooled.

Separation for the grinding beads

SCREE TYPE Outlet Screen For Separation Of Grinding Media From Slurry. Grinding beads size .5 mm to .7 mm.

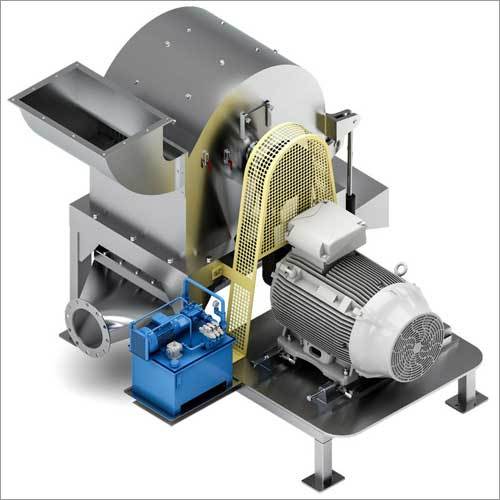

Main Drive

Will be 40 HP 3ph 1440 RPM and 440V of any standard make. Feeding pump is runned and controlled by a 1.5kW 2HP Variable Speed Mechanical Drive Box having the speed range of 40 Aca a 200 rpm. Mechanical Seal rinsing pump motor is 0.18kW.

Agitator Disc Peripheral Speeds

The speeds are 10 m/sec, fixed type Aca E CAca a c sec motor pulley.

Feeding Pump: Screw Pump of Size 1Aca A coupled with variable speed Gear Box Aca a M Seal Rinsing Pump A A Inch / Centrifugal Type.

Materials

Material parts which are subject to wear and in touch with the product are made of specific hardened steel and stainless steel.

Control Panel

Control panel mounted separately on the side of machine body is composed of Fully Automatic Star Delta Starter for main and D.O.L. for feeding Pump, start-stop buttons for motors; ON_OFF switch and ammeter; emergency stop button.

Production Capacity

The capacity of SFPM Aca a 42 completely depends on the product to be processed. It may differ between the average v 960 kg/s, but the actual values may vary during the operation.

Machine Limiting Values

Max. Product Pressure: 3 bar

Max Product Temperature: 110 C

Min. Temp. Of Cooling Water: 25 C

Max. Pressure of Cooling Water: 6 bar

Max. Cooling Water Pressure for Glycerine Vessel: 4 bar

MODEL | MAIN MOTOR HP | FEEDING PUMP HP | OUTPUT LTRS PER/MIN |

SFDM - 42 | 40 | 2 | 1.5 TO 6 |

SFDM - 64 | 60 | 2 | 2 TO 8 |

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

15

Establishment

1973

Working Days

Monday To Sunday

GST NO

27ARUPS7370Q1ZE

Certification

ISO 9001 : 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27ARUPS7370Q1ZE

Mira Bhayandar, Maharashtra

Proprietor

Mr Fayazulla Z. Sayed

Members since

21 Years

Address

SHANTA INDL. ESTATE, SHED NO-1, BEHIND DODHIA PETROL PUMP, W.E. HIGHWAY, KASHIMIRA-MIRA ROAD, Mira Bhayandar, Maharashtra, 401104, India

grinding mill in Mira Bhayandar

Report incorrect details