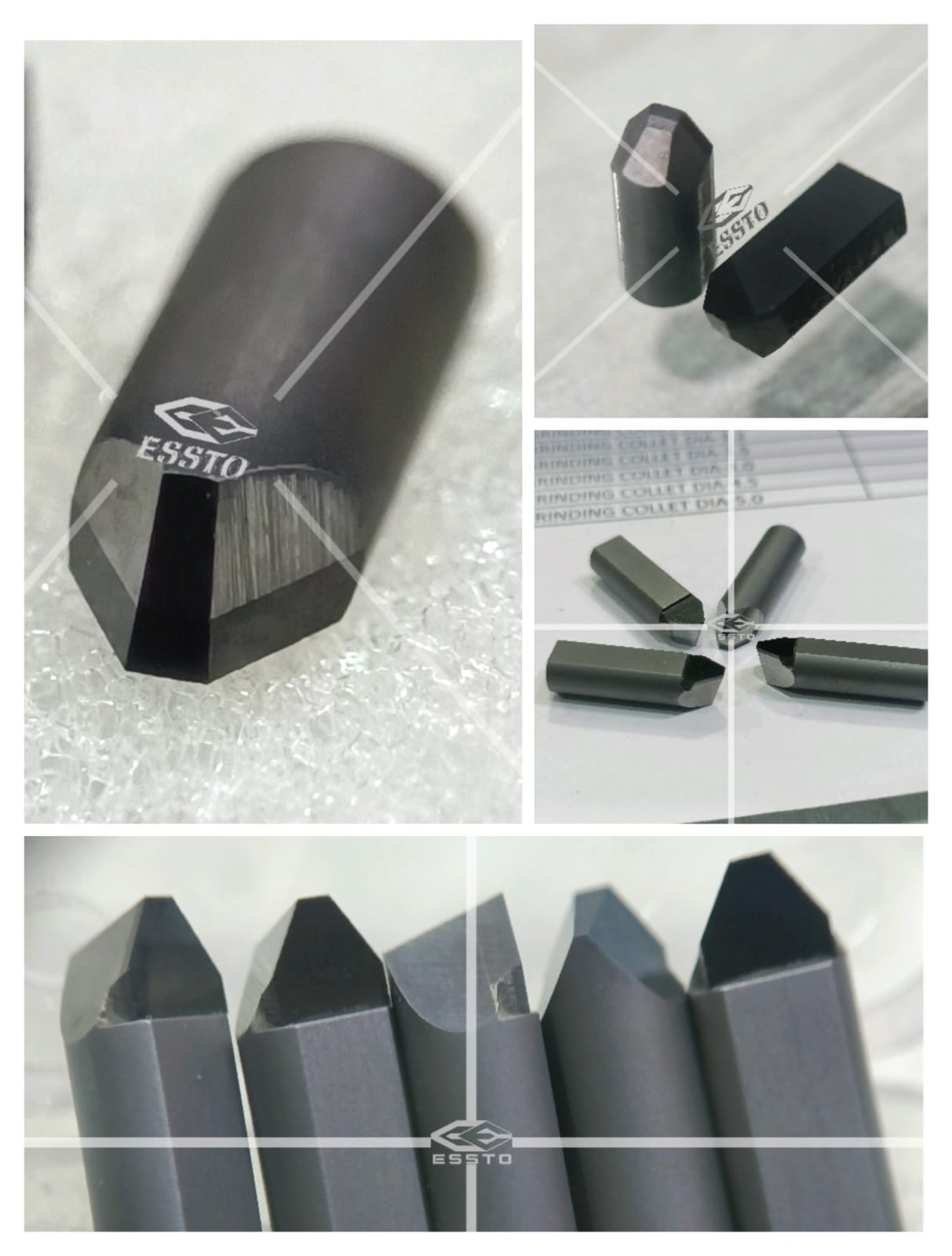

Pcd Boring And Notching Tools For Carbide Rollers

Price:

Get Latest Price

In Stock

Product Specifications

| Size | Vary |

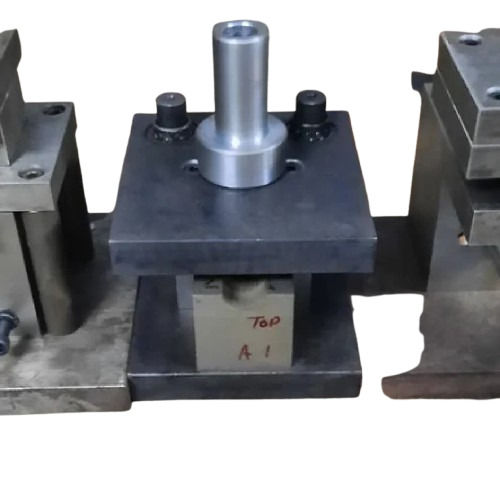

| Usage | Boring And Notching |

| Product Type | Cutting Tool |

| Payment Terms | Others |

Product Overview

Key Features

a Suitable for dry and wet cutting

PCD boring tools are used for machining various of tungsten carbide rollers. PCD tips for carbide roller notching.

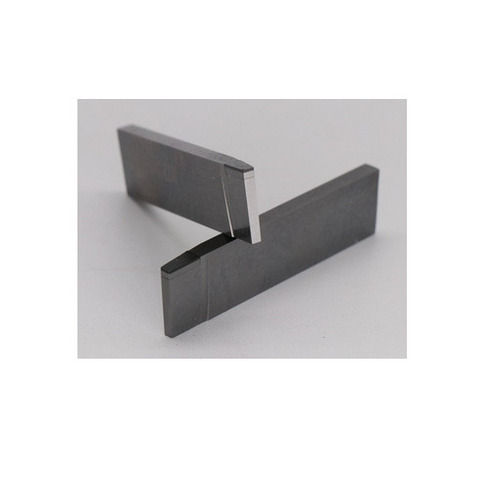

The PCD boring tools are made by PCD blanks (E6) brazing on the tungsten carbide body. Most common is full face pcd notching tools.

Specification

Applications of PCD boring tools:

PCD boring tools are used for machining various of tungsten carbide rollers. PCD tips for carbide roller notching.

Advantages of PCD boring tools:

high abrasive resistance and thermal conductivity

good surface finish

Long service life. The service life is 20-30 times more than carbide boring tools.

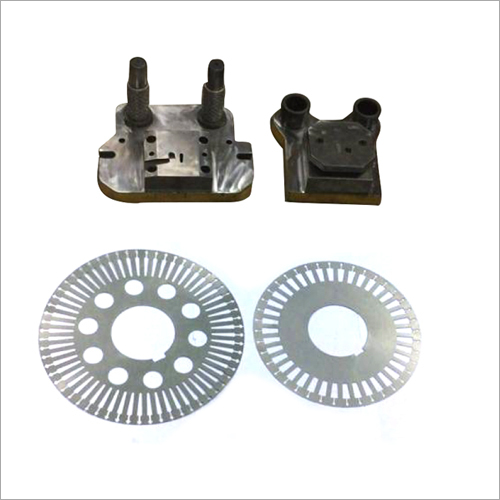

PCD inserts are mostly used in high, medium and low silicon content aluminum alloys, graphite, metal matrix composites, carbon fiber composites, titanium alloys, aluminum alloy ultra-finishing industries, aviation and auto parts, etc. In traditional machining applications, it not only greatly reduces the overall production cost, but also significantly improves the productivity and efficiency of the entire production operation, while greatly reducing equipment investment.

PCD boring tools Application range

Rolla Air Conditioning Compressor Partsa Slewing supporta Gear shafta Bearinga Cylindera Cylinder linera Hub unit bearinga Brake druma Brake disc.

Why Choose Our PCD Boring Tools

1. The raw material is excellent, and it is processed and sharpened by the element six PCD composite sheet.

2. Fine cutting edge, the hardness of diamond is about 8000HV, and the hardness is 10 times that of alloy. It has the advantages of low friction coefficient, high hardness and long service life. It can process a higher finish than conventional tools while reducing costs.

3. High-precision dimensions, tolerances of blade angle, blade tip, length, and equal division are strictly controlled within the tolerance of 0.02MM to ensure the stability of the life of each blade.

4. Complete specifications, various specifications and models can be produced, customized production according to the customer's use size, the manufacturer's supply makes you more assured.

Company Details

More SuperHard devotes to develop and produce advanced diamond & CBN grinding wheels to provide you a complete grinding solution, which is widely used in Petroleum & Geology Industry, Auto & Aviation Processing Industry, Cutting Tool Processing Industry, and Natural Diamond & Jewelry Processing Industry and etc. With the advanced bond systems (Vitrifified bond, Resin bond, Metal bond, Hybrid bond and electroplated), our products cover all grinding types, flflat grinding, cylindrical grinding, internal grinding, centerless grinding, profifile grinding, peripheral grinding, etc… Fit manual grinder and also CNC grinding center.

Business Type

Exporter, Manufacturer

Employee Count

25

Establishment

2023

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Zhengzhou, Henan

Export Manager

Mr. Peter

Address

No. 171, Zhongyuan Rd, Zhongyuan District, Zhengzhou, Henan, 000000, China

notching tools in Zhengzhou

Report incorrect details