Semi-automatic Oil Diffusion Vacuum Pump

Price:

Get Latest Price

Minimum Order Quantity :

5

In Stock

Product Specifications

| Ultimate pressure | 5 10-5 (Pa) |

| Pumping Capacity | 550 L/S |

| Critical pressure | 40 (Pa) |

| Backflow rate | 3 10-2 |

| Heating time | 30 min |

| Heating Power | 0.8-1 kw |

| Electric Voltage | 220V |

| Features | High Pumping, Observation Windows, Protection Device, Stretching Process |

| Payment Terms | Western Union, Telegraphic Transfer (T/T), Others, Cash in Advance (CID), Cheque, Cash Advance (CA) |

| Supply Ability | As per client requirement Per Month |

| Delivery Time | 3 Week |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Main Domestic Market | All India |

| Certifications | Wooden Pallets |

Product Overview

Key Features

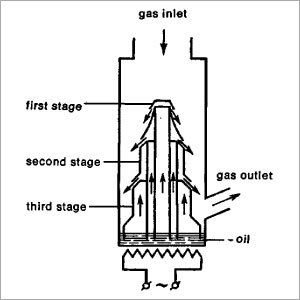

We are a competitive manufacturer, trader, exporter and supplier of Oil Diffusion Vacuum Pump. This pump is basically a equipment that is mainly used for getting the high vacuum (10-2 pa, 10-5 pa) condition. It can make high pumping system with valves, water cooled baffle, mechanical vacuum pump etc. Moreover, it is widely used for high technology fields of vacuum coating like Resistance evaporation coating machine, Multi-arc ion coating machine etc. if this Oil Diffusion Vacuum Pump want to obtain ultrahigh vacuum (up to 10-6Pa), it adopts liquid nitrogen cooling device and baking equipment,

Features:

- High pumping capacity, the pumping capacity from 480L/s to 130000L/s.

- It adds observation windows (sight glasses), oil inlet and outlet, the protection device for pump oil overheat, etc.

- It adopt stretching process, reduces weld crack and out gassing and increases strength.

- There are two kinds of heaters (electric heating wire and electric heating plate) as alternative when you place orders.

Applications:

Its widely used for high technology fields of vacuum coating ( such as Multi-arc ion coating machine, Magnetron sputtering coating machine, Resistance evaporation coating machine, Electron beam evaporation optical coating machine, Rolling vacuum coating, Continuous vacuum coating machine production line /In-line coating production line, etc), vacuum furnace ( such as, vacuum soldering/brazing furnace, vacuum annealing furnace, vacuum tempering furnace, vacuum sintering furnace, vacuum carburizing furnace, etc), electron, chemical industry, metallurgy, aviation, aerospace, material, creature medicine, atomic energy and universe probe, etc.

| Item | KT-100 | KT-160 | KT-200 | KT-250 | KT-300 | KT-320 | KT-400 | KT-500 | |||||||

| Ultimate pressure | 510-5 | ||||||||||||||

| (Pa) | |||||||||||||||

| Pumping Capacity (L/S) | 550 | 1800 | 2800 | 3500 | 4600 | 5000 | 8500 | 12000 | |||||||

| Critical fore-pump pressure | 40 | ||||||||||||||

| (Pa) | |||||||||||||||

| Backflow rate | 310-2 | ||||||||||||||

| mg/(cm2min) | |||||||||||||||

| Heating time | 30 | 35 | 40 | 45 | |||||||||||

| ( min) | |||||||||||||||

| Heating Power | 0.8-1 | 1.4-1.6 | 1.6-1.8 | 2.2-2.4 | 2.4-3 | 4~5 | 4~5 | 6~8 | |||||||

| (kw) | |||||||||||||||

| Electric Voltage | 220 | 380 | |||||||||||||

| (AC)V | |||||||||||||||

| Pump Oil Model | KS-3 | ||||||||||||||

| Pump Oil Volume | 0.15 | 0.45 | 0.55 | 1-1.4 | 1-1.6 | 1.4-1.8 | 3~4 | 4 | |||||||

| ( L) | |||||||||||||||

| Cooling water consumption | 180 | 250 | 300 | 350 | 400 | 420 | 500 | 600 | |||||||

| (L/H) | |||||||||||||||

| Inlet dimension | 100 | 160 | 200 | 250 | 300 | 320 | 400 | 500 | |||||||

| ( mm) | |||||||||||||||

| Outlet dimension | 32 | 50 | 65 | 65 | 80 | 80 | 100 | 100 | |||||||

| (mm) | |||||||||||||||

| Recommended forepump speed (L/s) | 4 | 8 | 15 | 15 | 30 | 30 | 70 | 150 | |||||||

| Dimension | L(Length) | 320 | 420 | 530 | 473 | 695 | 725 | 885 | 1010 | ||||||

| B(Width) | 260 | 315 | 390 | 450 | 505 | 525 | 665 | 815 | |||||||

| H(Height) | 365 | 505 | 575 | 650 | 726 | 830 | 925 | 1165 | |||||||

| Net weight (kg) | 14 | 31 | 39 | 48 | 89 | 100 | 175 | 185 | |||||||

| | | | | | | | | | | | | | | | |

| Item | KT-600 | KT-630 | KT-800 | KT-900 | KT-1000 | KT-1200 | KT-1400 | KT-1600 | |||

| Ultimate pressure (Pa) | 510-5 | ||||||||||

| Pumping Capacity (L/S) | 17500 | 20000 | 30000 | 40000 | 50000 | 60000 | 90000 | 130000 | |||

| Critical fore-pump pressure (Pa) | 40 | ||||||||||

| Backflow rate mg/(cm2min) | 310-2 | ||||||||||

| Heating time ( min) | 50 | 60 | 65 | 70 | 80 | 90 | |||||

| Heating Power (kw) | 8~9 | 9~11 | 13-13.5 | 14-16 | 17-20 | 28-30 | 38-40 | 48-50 | |||

| Electric Voltage (AC)V | 380 | ||||||||||

| Pump Oil Model | KS-3 | ||||||||||

| Pump Oil Volume | 6~7 | 7~8 | 12~14 | 14-15 | 15-16 | 22 | 38 | 50 | |||

| ( L) | |||||||||||

| Cooling water consumption (L/H) | 800 | 850 | 1200 | 1350 | 1500 | 2600 | 3400 | 4300 | |||

| Inlet dimension ( mm) | 600 | 630 | 800 | 900 | 1000 | 1200 | 1400 | 1600 | |||

| Outlet dimension (mm) | 150 | 160 | 200 | 200 | 300 | 300 | 320 | 320 | |||

| Recommended forepump speed (L/s) | 300 | 600 | 600 | 600 | 1200 | 1200 | 1200 | 2500 | |||

| Dimension | L(Length) | 1145 | 1170 | 1520 | 1843 | 1990 | 2235 | 2556 | 2900 | ||

| B(Width) | 975 | 1010 | 1275 | 1283 | 1290 | 1750 | 1950 | 2100 | |||

| H(Height) | 1444 | 1275 | 1870 | 1950 | 2220 | 2465 | 2950 | 3355 | |||

| Net weight (kg) | 375 | 420 | 670 | 830 | 990 | 1500 | 2150 | 2500 | |||

Company Details

Focusing on a customer-centric approach, WINNER VACUUM PACKING PRIVATE LIMITED has a pan-India presence and caters to a huge consumer base throughout the country. Get Pumps & Pumping Equipment from WINNER VACUUM PACKING PRIVATE LIMITED at Trade India quality-assured services.

Business Type

Exporter, Importer, Manufacturer, Service Provider, Distributor, Supplier, Trading Company

Employee Count

6

Establishment

2013

Working Days

Monday To Sunday

GST NO

27AOWPR7032K1Z4

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AOWPR7032K1Z4

Mumbai, Maharashtra

Sales

Mr. Ravindra Raghuwanshi

Address

124, Shrikrishna Industrial Estate, Opp. Chek Naka, Dahisar (E), Mumbai, Maharashtra, 400068, India

diffusion vacuum pump in Mumbai

Report incorrect details