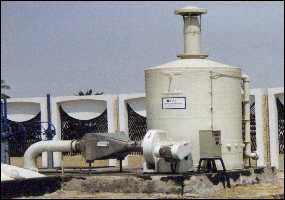

Odour Control System - Multi-stage Wet Chemical Scrubber With Plc Automation | 99% H₂s Abatement, Online Monitoring, Optimized Chemical Consumption, Small Footprint

Price:

Get Latest Price

In Stock

Product Specifications

| Airflow Capacity | Variable |

| Stages | 2-3 |

| Abatement Efficiency | >99% |

| Material | Stainless steel |

| Control System | PLC based |

| Monitoring | Online |

| Usage | Industrial odour control for large volumes of air with high and variable odour challenges, typically involving ammonia, amines, hydrogen sulfide, or other acidic gases. Suitable for various industries, including waste treatment and manufacturing. Reduces odour emissions to meet environmental regulations. |

| Features | High odour loads, Instantaneous adapts, 99% H2S abatement, Optimised chemical, Small footprint, Full turnkey service |

Product Overview

Key Features

Odour Control System

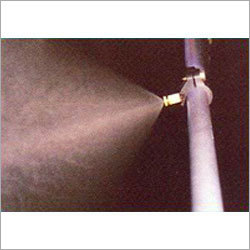

Wet Chemical Scrubbing is a very effective system for abating large air volumes with high and or variable odour challenges that are difficult for biological systems to treat. A wet chemical scrubber will normally have either 2 or 3 chemical stages depending on the odour make up.

Where ammonia or amines are likely to be present in the gas stream a first stage acid stage scrubber would be used followed by a two stage alkaline process for the removal of acidic gases such as Hydrogen Sulphide (H2S). Otherwise gas streams that are predominately acidic in nature will be passed through a two stage scrubbing process with the first stage using an aqueous solution of Sodium Hypochlorite to oxidise the load and a second caustic polishing stage to remove chlorinated products or chlorine.

If both alkaline and acidic gasses are present a three stage system will be used consisting of all of the above stages. Chemical consumption is the critical operational cost and therefore our control system designs minimise dosing rates whilst maximising abatement efficiency.

We offer full PLC based Human Machine Interface panels linked to on-line inlet and outlet odour monitoring to maintain system efficiency.

Benefits:

Treats high odour loads

Adapts to variable rates instantaneously

> 99% H2S abatement

Online inlet and outlet odour monitoring

Optimised chemical consumption

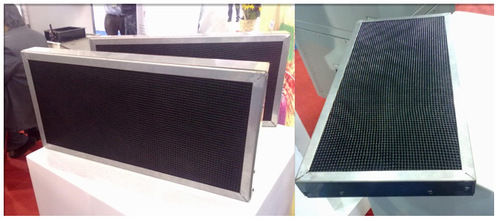

Optional activated carbon polishing filters if required

10 year media life

Small footprint

Full turn-key service available

Company Details

Focusing on a customer-centric approach, OMEGA ENVIRO POWER SYSTEMS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Pollution Control & Monitoring Equipment in bulk from OMEGA ENVIRO POWER SYSTEMS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Establishment

2010

GST NO

33ALVPR4156L1ZD

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 33ALVPR4156L1ZD

Chennai, Tamil Nadu

Proprietor

Mr. Ramesh Ranganathan

Address

No:22, Anupam Flat, L&t Colony, Manapakkam, Chennai, Tamil Nadu, 600116, India

odour control system in Chennai

Report incorrect details