Octagonal Blender - Aisi 316 Stainless Steel, 25 Kg To 5000 Kg Batch Size | Cgmp Compliance, Ideal For Homogeneous Mixing And Lubrication Of Granules

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Aisi 316/304 |

| Capacity | 25Kg-5000Kg |

| Shape | Octagonal |

| Drive | Rigid, Enclosed |

| Gearbox | Reduction |

| Motor | Included |

| Mixing Time | 5-15 Mins |

| Features | Fast Mixing, Homogenous Blend, Dry Powder Mixing, Granule Blending, Cgmp Compliant, Multiple Batch Mixing, Versatile Application, Efficient Process |

| FOB Port | MUMBAI |

| Payment Terms | Letter of Credit at Sight (Sight L/C) |

| Main Export Market(s) | Asia, Central America, South America, Western Europe, Middle East, Africa |

| Main Domestic Market | All India |

Product Overview

Key Features

Effective Process Technic of uniform mixing, lubricating & blending of dry powder & granules

Application & Process :

Blenders are used for mixing, lubricating and blending in Pharmaceutical, Nutraceutical, Food, Chemical, cosmetics, ceramics, pesticide, plastics and other Allied industries

The octagonal shape blenders have six corner of product container for more tumbler effect to the material for fast and homogenizing mixing. It can perform homogenously dry mixing of free flowing powders, granules requiring low shearing force, Mixing and Blending of particles with rapid intermixing of particles irrespective of varying specific gravities. The material is loaded into the blender drum. The octagonal blender is tumbles the material in the container and spread out. The mixing is achieved in 5 to 15 minutes with better homogeneity.

Salient Features :

a cDesign is cGMP - Current Good Manufacturing Practices compliance

a cAll Product contact parts AISI 316 & non contact parts AISI 304.

a cOctagonal shape product container for Ideal dry mixer for lubrication of granules and homogenization mixing of multiple batches in to single batch.

a cAvailable Capacity model in octagonal blender 25 kg to 5000 kg batch size.

a cEnclosed rigid drive with reduction gear box and motor.

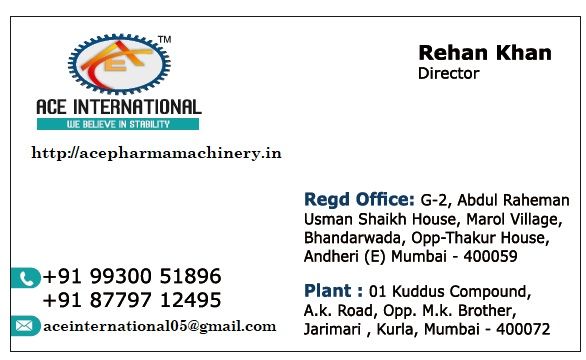

Company Details

Profile Since our establishment in the year 2005, we, A Ace International are engaged in manufacturing and supplying an optimum quality range of Pharmaceutical Machinery & Spare Parts. Offering Spare Parts Of Rapid Mixer Granulator, Fluid Bed Dryer, Capsule Printing Machine Blister Packing Machine, Conical Blender, Double Cone Blender, Industrial Blender, Vibro Sifter Machine, Industrial Vibro Sifter, Multi Deck Vibro Sifter, Bolus Tablet Press GMP Model, Double Sided Rotary Tablet Machine, Central Drive & Pre-Compression Tablet Press GMP Model , Tablet Press, Fluidized Bed Coater , RMG Machine Lab Model & Production etc. Reckoned for quality attributes such as dimensional accuracy, corrosion & abrasion resistance, long functional life and fine finish, these components and spare parts are utilized extensively in engineering industries. We design and develop these products using certified material to ensure their compliance with international standards. Prior to dispatch, the entire range of finished products is quality tested at our advanced facility on various set parameters. Our quality controllers are highly efficient and help us provide top-notch quality components and spare parts to the clients located across the nation. In our business operations, we are aided by a team of adroit professionals, with whose cooperation we are able to fulfill the exact requirements of clients and garner a rich Clientele in the market. The infrastructure facility of our firmincorporates latest technology, and is outfitted with most advanced machine and tools. We hold expertise in offering our clients wide range of Pharmaceutical Machinery Spare parts that is valued for smooth functioning, durability and superior quality.We offer them in different technical specifications and are used in varied industrial applications. We offer them in different specific sizes and dimensions and are easy to operate. These products are fitted with rotary action and are available at most affordable rates

Business Type

Exporter, Manufacturer

Employee Count

4

Establishment

2005

Working Days

Monday To Sunday

GST NO

27AAKFA9123E1ZK

Payment Mode

Letter of Credit at Sight (Sight L/C)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAKFA9123E1ZK

Mumbai, Maharashtra

Mr R. M. Khan

Address

Factory : 01, Kuddus Compound, A.k. Road, Opp. M.k. Brother Jarimari , Kurla, Mumbai, Maharashtra, 400072, India

octagonal blender in Mumbai

Report incorrect details