Novec1230 Firetrace Suppression System - Ul Approved Material, 1.2x0.55x0.55m, Red | Suitable For Electrical & Server Applications, 12-month Warranty

Price: 94400.00 INR / Set

(80000.00 INR + 18% GST)

Get Latest Price

MRP:

105000.00 INR / Set

Weight :

20.00 Kilogram

1 Pack Contains :

1

Minimum Pack Size :

1

In Stock

Product Specifications

| Usage | fire suppression system |

| Product Type | FIRE DETECTION TUBE BASED SUPPRESSION SYSTEM |

| Temperature Range | 100 Celsius (oC) |

| Material | UL APPROVED |

| Alarm | YES |

| Color | RED |

| Weight | 20 Kilograms (kg) |

| Warranty | 12 MONTHS |

| Dimension (L*W*H) | 1.2x.55x.55 Meter (m) |

| Input Power | 230 Volt (V) |

| Application | ELECTRICAL & SERVER APPLICATION |

| FOB Port | New Delhi |

| Payment Terms | Others |

| Supply Ability | 500 Per Month |

| Delivery Time | 4 Week |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | FIRETRACE TUBE SYSTEM |

| Main Export Market(s) | Asia |

| Main Domestic Market | All India |

| Certifications | LPCB APPROVED, UL APPROVED AND CE APPROVED |

| Pkg Box Breadth | 25.00 in |

| Packsize | 1 |

| Product Unit | 1 Set/Sets |

| Stock Quantity | 100 |

| Currency | INR |

| Shipping Type | order_percent |

| Min Quantity | 1 |

| GSTIN | 18% |

| Mop | 1 |

| Pkg Box Length | 25.00 in |

| Brand Name | FIRETRACE |

| Returnable | No |

| Unit Type | Set/Sets |

| Max Quantity | 100 |

| Shipping Rate | 3.00 |

| Weight | 20.00 Kilogram |

| Moq | 1 |

| Price | 80000.00 INR (Approx.) |

| MRP | 105000.00 INR |

| Color | RED |

| Price Type | fixed |

| Pkg Box Height | 25.00 in |

| Minimum Ordered Packs | 1 |

| Minimum Order Quantity | 1 |

Product Overview

Key Features

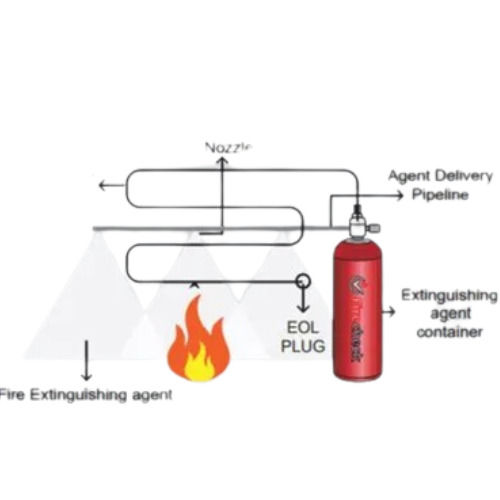

Herea s how they work:

During a fire, the portion of the tube nearest the point where the most heat is detected ruptures, forming a spray nozzle.

The pressure decreases as the tubing releases fire suppression chemical from the cylinder through the spray nozzle (burst hole) to effectively suppress the fire.

A direct release system can be installed to protect multiple enclosures using a single cylinder by routing additional tubing to each enclosed space.

We recommend direct release systems for protection of electrical cabinets. For protection of vehicles or CNC machines, we recommend indirect release systems.

What is a Fire Suppression System?

A fire suppression system is any product designed to stop a fire from spreading. It gets the name suppression system as it aims to hold back the fire and the damage it may cause. Preventing the fire from spreading mitigates losses and allows time for emergency personnel to respond. One example of a fire suppression system is a fire sprinkler system. Clean agent and dry chemical systems, like those offered by Firetrace also qualify as fire suppression systems.

While sprinkler systems are the most common type of fire suppression system, some applications require special hazard fire suppression systems that do not use water. These systems are unique in that they can deal with hazards where water could actually do more harm than good. Within fire science, there are several classes of fires: class A, B, C, D, and K. The fuel of the fire will dictate what can put it out. Class A fires, for example, involve wood, and a sprinkler system would work well. A Class C fire, on the other hand, is an electrical fire and that may get worse by trying to suppress it with water. In summary, the specific environment will determine which system will work best.

Types of Fire Suppression Systems

Engineered vs. pre-engineered fire suppression systems also need discussion. Engineered fire suppression systems will protect an entire room. Firetrace, for example, uses clean agents that are safe with electronics and can be inhaled without doing any harm to a person.

Pre-engineered systems are used to protect small compartments or micro-environments. Engine compartments and electrical panels are good examples of where these types of systems would provide protection. They are also useful for suppressing fires in CNC and EDM machines.

Firetrace pre-engineered fire suppression systems are available in two configurations: indirect release and direct release. Watch the video below to learn about the two different Firetrace pre-engineered fire suppression systems:

Fire suppression agents: Within pre-engineered fire suppression systems, there is a slew of agents that can be used. Class K systems typically have foam fire suppressants or other wet chemical agent options to help reduce the spread of the fire within the space. Engines, by contrast, are typically protected using ABC Dry Chemical powder, which can effectively suppress Class A, B, and C fires.

Detection options: A pre-engineered system usually comes in two forms or categories. The first is an active detection system, while the second is a non-electric detection system. Active detection requires an electrical power source, constantly seeking out heat or smoke. A non-electric detection system relies on zero electricity.

Non-electric detection systems, including the Firetrace pre-engineered system, utilize pneumatic detection tubing that can be installed inside and throughout hazards. Since heat rises, it works to trigger the pneumatic detection tube. If the heat or fire comes in contact with the tube, the tubing will burst open at the point of contact.

Company Details

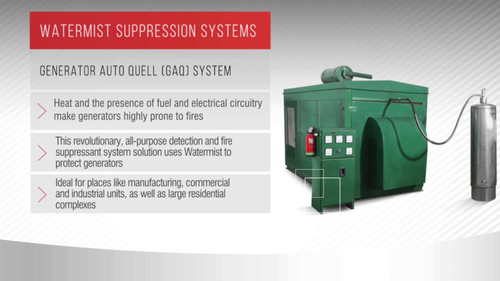

Fire Engineering Technology, started with the vision to cater the Hospitals, Hotels, Government sector, and other sectors like Mining and Industries to provide best quality of Fire Safety system with satisfaction. We are leading manufacturer and supplier of all type industrial Fire suppression system products like -Novec-1230 fire suppression system, Novec-1230 gas flooding system, FM-200 fire suppression system, FM-200 gas flooding systems, HFC227ea gas suppression system, Kitchen fire suppression system, Vehicles fire suppression system and Automatic fire detection and suppression system (AFDSS) for Mining Vehicles HEMM. We are providing service all over India.

Business Type

Manufacturer, Service Provider, Distributor, Supplier, Trading Company, Wholesaler

Employee Count

25

Establishment

2014

Working Days

Monday To Sunday

GST NO

07AADFF6834G1ZG

Payment Mode

Others

Certification

ISO 9001:2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AADFF6834G1ZG

New Delhi, Delhi

Accepts only Domestic inquiries

Director

Mr Anil Mishra

Members since

8 Years

Address

Plot No. 71, Sewak Park, Dwarika More Metro Station, Near Pillar No. 776, Uttam Nagar, New Delhi, Delhi, 110059, India

Report incorrect details