Multi Utility Coffee And Grain Drier

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless steel |

| Drying rate | 2%-3%/hr |

| Fuel type | Agro waste |

| Control | Automatic |

| Usage | Coffee, grains, pulses drying |

| Dimensions | Variable |

| Capacity | Variable |

| Features | Uniform drying, Energy efficient, Stainless steel, Auto control, High quality, Easy operation |

| Payment Terms | Others, Cash Against Delivery (CAD) |

| Delivery Time | within 1 Week |

| Main Domestic Market | All India |

Product Overview

Key Features

the solution is SKF Multi application Drier, completely designed and synthetic, maintaining in thoughts the unique wishes of farmers/merchants/industries!

The layout :

For the excellent technique to capture the incredibly competitive export market, with espresso/grains/pulses of super fine, choose SKF Multi utility Drier. thoroughly made from chrome steel, with an auto manage hot air and moisture, SKF Multi software Drier can produce all styles of coffee beans/grains/pulses of global great.

The additives :

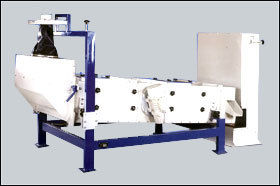

Feeder for Drier

Drier Chambers SS

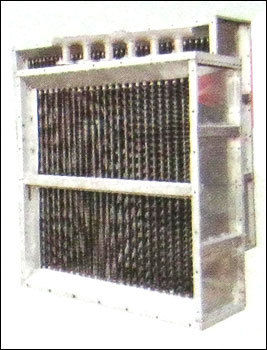

warm Air heat Exchanger

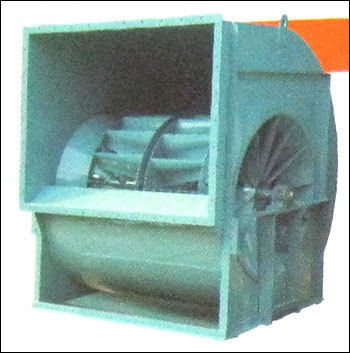

Centrifugal Blower

Chimney

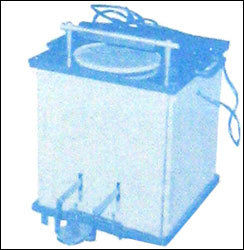

vehicle manipulate for Moisture and Temperature

The Feauters :

Moisture content decreased is: 2% - 3%/hr.

state-of the-art outstanding green, multi software drier.

Futuristic design and competitively priced-desires minimum strength and gas (coffee bean shells/fireplace timber/agro waste).

auto-manage air and temperature for uniform drying.

general automation for clean operation and renovation.

absolutely product of stainless steel-upkeep loose.

Hygienic world elegance espresso, grains, pulses guaranteed.

warm air technology-indirect heating for uniform drying.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Working Days

Monday To Sunday

GST NO

29AAHCS9043D1Z6

Certification

ISO 9001 : 2000

Related Products

More Product From This seller

Seller Details

GST - 29AAHCS9043D1Z6

Mangaluru, Karnataka

Manager

Mr Vivek Vallabah

Address

Door no. 129, Bannadka Belvai, Near Moodbidri, Mangaluru, Karnataka, 574213, India

Food Processing Machinery in Mangaluru

Report incorrect details