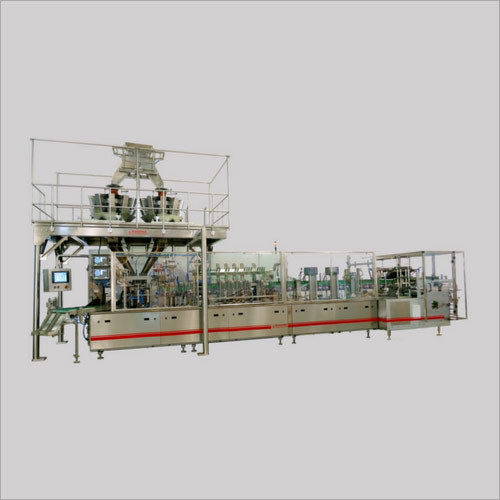

Multi Track Form Fill & Seal Machine - Food Grade Stainless Steel, 3-10 Tracks, 1-100 Gm/ml Packing Range | Fully Automatic With High Speed And Versatile Application For Liquids, Powders, Granules, And Pastes

Price:

Get Latest Price

In Stock

Product Specifications

| Product Application | Liquid, Powder |

| Quantity Packed | 1-100 Gm/Ml |

| Tracks | 3-10 |

| Speed | 65-90 Pouch/Min |

| Controller | Plc Based |

| Material | Stainless Steel |

| Dimensions | 4000X1600X2750 Mm |

| Features | Multi-Track, High Speed, Versatile, Hygienic, Economical, Efficient, Durable, Easy Operation |

Product Overview

Key Features

We expertly deal and distribute multi track form fill & seal

machine. It is used to pack liquid paste and powder substances like

shampoo, Vaseline, lotion, coffee powder etc. Our multi track form fill

machine is trouble-free for secondary packing of the goods. These

machines are fully automatic and are manufactured in keeping with our

strict quality control process. We also produce multi track form seal

machine for long lasting and hygienic packing. When it comes to the top

multi track form fill & seal machine exporters from India, we are

unrivaled champions in the field.

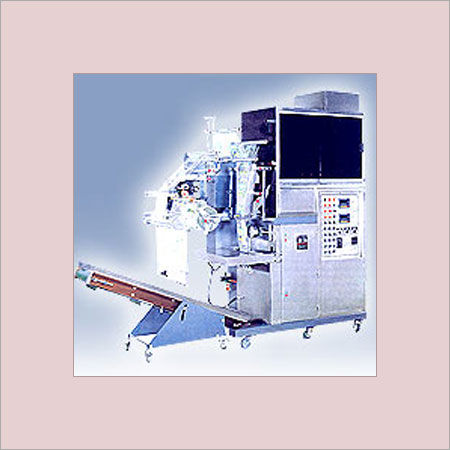

Model No. AIP/MT/45

- Application: Tablets, Panmasala, Tobacco, Jaljira, Cereals, Coffee Powder, Tea, Detergents, Pharmaceutical Powder, Namkeen, Henna, etc.

- Packaging Range: 1 -100 gm

Model No. AIP/MT/55

- Application : Shampoo, Vaseline, Creams, Lotions, Tomato Ketchup, Sauces, Pastes, Honey, Liquid Soap, etc.

- Packaging Range: 1-100 ml

Technical

Specifications

Product application | Liquid, Paste, Powder, Granules |

Quantity to be packed | 1 ml/gm-100 ml/gm |

No. of tracks | 3-10 tracks (Depends upon pouch width) |

Machine speed | 65-90 Pouch/Min/Track |

Temperature Controller | PID Based |

Machine Control | PLC (Programmable Logic Control) based |

Roll Width | 400-800 mm |

Roll Diameter | 400-800 mm |

Feeding System | Sticky Powder/Liquid/Grains Auger Filler/Piston |

Contact parts | Food Grade Stainless Steel SS 316 |

Pouch length/Type | Programmable/Four side sealing (with/without |

Laminate unwinding system | Servo based/ electromagnetic clutch and break |

Web controller | Electronic/Pneumatic Hydraulic Web Edge controller |

Compressed Air requirement | 2 CFM @ 6 Bar |

Electric Supply | 440 V, Three Phase, 50 Hz |

Power Consumption | 5-9.5 kw |

Machine Dimension | L (4000) X W (1600) X H (2750) mm |

Net Weight | 1200-2100 kg |

| Optional Attachments | Pneumatic coding device, collating system, notching |

Salient Features

Features | Advantages | Benefits |

Option of 4 -10 | Option of | Time |

Batch Cutting | Cuts the Batch | Ease of |

Three Side seal | Less laminate | Savings on |

Wide product | Versatile | Multi Purpose |

Zipper Pouch | Pouch Can be | Repeat usage |

Machine is | Displays/controls | Optimum |

Jacketed Hopper | For Liquid | Better Feeding |

Food Grade | No rusting | Long Life, |

Laminate | Maintains | Better Sealing |

Intermittent | Efficient, | Savings on |

Error Detection | Detection and | High Runtime |

Quality | High Quality | High Run Time, |

Notching Device | Notch is | Ease of Tearing |

Collating | Automatic | Less Labour |

Pneumatic | To Print M.R.P, | Helps In |

Company Details

Focusing on a customer-centric approach, Albasit India Packaging has a pan-India presence and caters to a huge consumer base throughout the country. Buy Packaging Machine in bulk from Albasit India Packaging at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Establishment

2003

Working Days

Monday To Sunday

Payment Mode

Cash Against Delivery (CAD), Cash Advance (CA)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Faridabad, Haryana

Proprietor

Mr. Aasif

Address

Plot No. 3665, Street No. 3, Air Force Road, Near Nain Chowk, NIT, Faridabad, Haryana, 121005, India

form fill seal machines in Faridabad

Report incorrect details