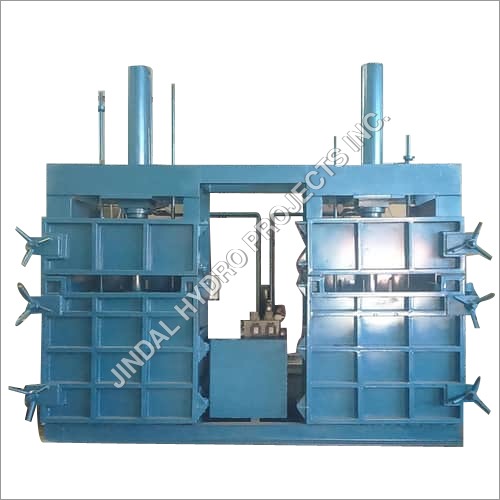

Holding vast expertise in this domain, we have been able to manufacture and export an impeccable quality Modern Hydraulic Baling Presses. Under the strict vigilance of our expert professional these baling presses are engineered using modern manufacturing techniques. Find usage in paper industries, these bailing presses are perfect for processing of waste paper, rolling paper cuts, corrugated paper broke and white & colour paper broke. We duly check Modern Hydraulic Baling Presses on various quality norms before supplying to clients. Features: Anti-corrosive body Withstand harsh conditions High efficiency Salient Features: Baling: These machine perform pressing operations on loose material to change bale shape Less cost: Reduction of transportation cost by 70% Handling Charges: Considerable saving in Handling charges. Less space: Saving of Godown space when material is stocked in the form of bales. Save time: Storing of material in less time. No wastage: No wastage of material while shifting. Easily countable in bale form. Safety: Extra more protection from moisture, heat and dust for baling material. Technical Specifications: Bale size: 36"x28"x21" (When bale weight: 150kgs.) Bale size: 36"x28"x18" (When bale weight: 100kgs.) No. of bales per hr: 8 to 10 Nos. Motor: 10 H.P. for 150 kgs 7.5 H.P. for 100 kgs 5 H.P. for 75 kgs. Electrical Push Button Operation Area required: 20ft. x 8 ft. Machine height from ground level: 14 ft. Working System: Bale box is movable on wheels. Hydraulic Cylinder Motor, Pump, Valves, Oil Tank is on top of press. Centre main press is fixed with foundation bolts. Two people required for filling straw, strapping the bale and operating the press. Initially straw is filled when bale box is outside. Box with straw is brought under the main press. The material is pressed with oil hydraulic force from top of the cylinder. After pressing open the doors and strap the bale.