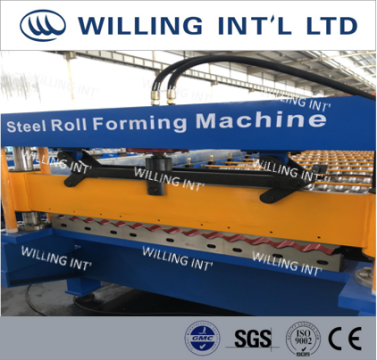

Mitsubishi Controller T8 Profile Metal Roof Roll Forming Machine With Ce Certificate Application: Industrial

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | 15M X 1.8M X 1.5M |

| Motor Power | 7.5Kw |

| Hydraulic Power | 2.2Kw |

| Roller Material | No.45 Steel |

| Cutter Material | Cr12 Mould Steel |

| Shaft Diameter | 72Mm |

| Features | High Accuracy, Automatic Operation, Long Life, Easy Operate, Durable Design, Precise Sheets, Simple Install, Easy Maintain |

Product Overview

Key Features

Forming speed: About 20- 25m/min

Power Requirement:

Main motor power: 7.5 Kw(Depend on final design)

Hydraulic station power: 2.2Kw(Depend on final design)

Material of forming rollers: No.45 steel, plated with chrome on surface.

Material of cutter: Cr12 mould steel with quench treatment, HRC58-60

Material of shaft:

High quality 45# steel, with heat treatment.

Roller grinder milling.

Shaft diameter: 72mm

Controlling system: Mitsubishi PLC & converter

Total weight of machine: About 9500KGS

Machine's size: About 15mA 1.8mA 1.5m (Depend on final design)

Shipping: 1x40GP container can load one machine

Roll Forming System:

1a Roller material is high grade No.45 forged steel plated with hard chrome, by digital- controlled procession.

2a 40mm thickness wall for forming system to ensure machine 15 years long life.

Bearings inside rollers:

Bearings inside the forming rollers to allow machine run with less loading, so that machine rollers not easy to be damaged to prolong machine life. More important, machine can get more precise sheet because of bearing designing.

High Accuracy:

1a Shaft material is No.45 steel with diameter 72mm, strong and durable.Shafts for rollers are tooled by grinding machine 2 times. Ensure product accuracy.

2a Finished shafts from grinding machine,rollers on these shafts can ensure final sheet accuracy.

Automatic & Easy Operate:

Machine long life: Roller material is high grade No.45 forged steel,plated with hard chrome,processed by digital-controlled procession.

Mitsubishi PLC with touch screen. Friendly man-machine interaction.The system is simple to learn and easy to operate.

Automatic Operation:once you set quantity and length of product,machine will produce product automatically.

Control Quality Well:

Zhongyuan factory is a "All-in-house source" from raw material to the final high-precision forming machine. All are done in our factory. Quality and delivery time can be controlled here.

Simple to install and easy to maintain:

You only need to connect some tubes and wires in your factory. Video and manual will show you how to do.

Our experienced technicians can supply overseas service.

Company Details

We are manufacturer for metal roll forming machine since 2003. Good quality and reasonable rate for our customers. 1.Zhongyuan is a from raw material to the final high-precision forming machine.All are done in our factory. Your machine quality and delivery time can be controlled here if you choose us. 2.With technical support by our 20 years experienced engineers and technicians, you can get our suggestion and solution within 24 hours. 3.You can get guarantee lifetime services for our machines. 4.Simple to install and easy to maintain. >> Our machines are well installed and tested before delivery. You only need to connect some tubes and wires in your factory. Video and manual will show you how to do. >> Our experience technicians can go to your factory and train your workers. >> We have exported 85 sets machines to India since 2008. You can trust our experience and solution for your deal between us.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

60

Establishment

2003

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Hangzhou, Zhejiang

Sales Manager

Mrs May Fu

Address

No.228, Yongli, Nanyang Street, Xiaoshan District, Hangzhou, Zhejiang, 311227, China

roof roll forming machine in Hangzhou

Report incorrect details