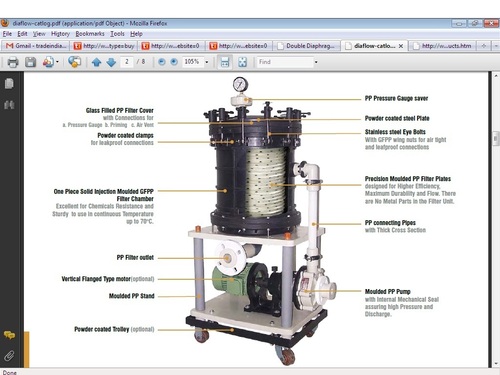

Micro Filtration System - Spuny Porous Membrane Technology, 0.1-10 Micron Particle Separation, Compact Design, Low Sludge Production, Process Automation

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless steel |

| Filtration Range | 0.1-10 um |

| Number of Units | 3 |

| Process Type | Cross-flow/Dead-end |

| Usage | Raw water microfiltration, particle and microorganism removal |

| Pressure Rating | Variable |

| Dimensions | 1000x200x300mm (approx.) |

| Features | High efficiency, Compact design, Low sludge, Automated process, Reduced steps |

Product Overview

Key Features

MCF separates particles of size 0.1 microns (um) through 10 um. MF membranes have received particular attention because of their ability to remove turbidity, particles and coliform bacteria. Although MF isn't serious obstacle for viruses, when used in conjunction with a disinfection process, it can control microorganisms in the feed water. MF includes two common forms of filtration: cross flow separation and dead-end filtration . In cross flow separation, a fluid runs parallel to a membrane. There's some pressure involved across the membrane, which causes some of the fluid to pass through the membrane, while the remainder continues to move across the membrane, cleaning it. In dead-end filtration, or per-pendicular filtration, all of the fluid passes through the membrane, and all of the particles that cannot fit through the pores of the membrane are stopper.

Feel free to contact for Pure'fect Water Solutions.

Company Details

Focusing on a customer-centric approach, INDIAN ION EXCHANGE & CHEMICALS LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Get Water Treatment Plants from INDIAN ION EXCHANGE & CHEMICALS LTD. at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Distributor, Supplier, Trading Company

Employee Count

200

Establishment

1993

Working Days

Monday To Sunday

GST NO

24AACCI2242R1ZF

Certification

ISO 9001:2008

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AACCI2242R1ZF

Ahmedabad, Gujarat

Marketing Officer

Mr Ravi Khakhariya

Address

D-64, Diamond Park, G.I.D.C. Naroda, Ahmedabad, Gujarat, 382330, India

industrial filtration systems in Ahmedabad

Report incorrect details