Metal Injection Molding (Mim) For Medical Devices

Price:

Get Latest Price

In Stock

Product Overview

Key Features

The MIM Process

Mixing a Blend fine metal powders with proprietary ingredients to create viscous feedstock.

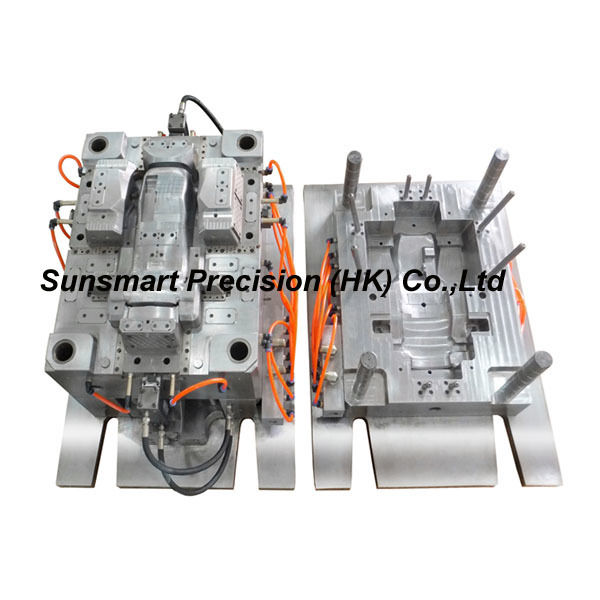

Molding a Form complex shapes using standard injection molding tools and equipment.

Debinding a Prepare molded components for high temperature sintering.

Sintering a Subject components to temperatures up to 1600A C to achieve up to 99% densification.

Finishing a Add standard engineering detail as needed (e.g., plate, heat treat, black oxide).

MIM Materials:

a c Stainless Steels

a 304L, 316 L, 17-4 PH, 420, 440

a c Low Alloy Steel

a 4605, 4105, 2200

a c Titanium Alloys

a Ti, Ti-6Al-4V

a c Soft Magnetic Alloys

a Fe-Si, Fe-Ni, Fe-Co

a c Tungsten Alloys

a 95%W-Ni-Fe, 97%W-Ni-Fe

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

240

Establishment

2004

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Nanjing, Jiangsu

Sales Manager

Mr Tony Wang

Address

24F, No.8, Zhongshan Nanlu, Nanjing, Jiangsu, 210005, China

custom metal parts in Nanjing

Report incorrect details